Joint treatment method for enabling anchor rods to densely penetrate through lining waterproof layer in large range

A node processing, large-scale technology, applied in the direction of shaft lining, tunnel lining, bolt installation, etc., can solve the problems of reducing the strength of the bolt support structure, damage to the waterproof board, increasing the truncation process, etc., to improve the quality of waterproofing projects, The effect of meeting the progress needs and expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

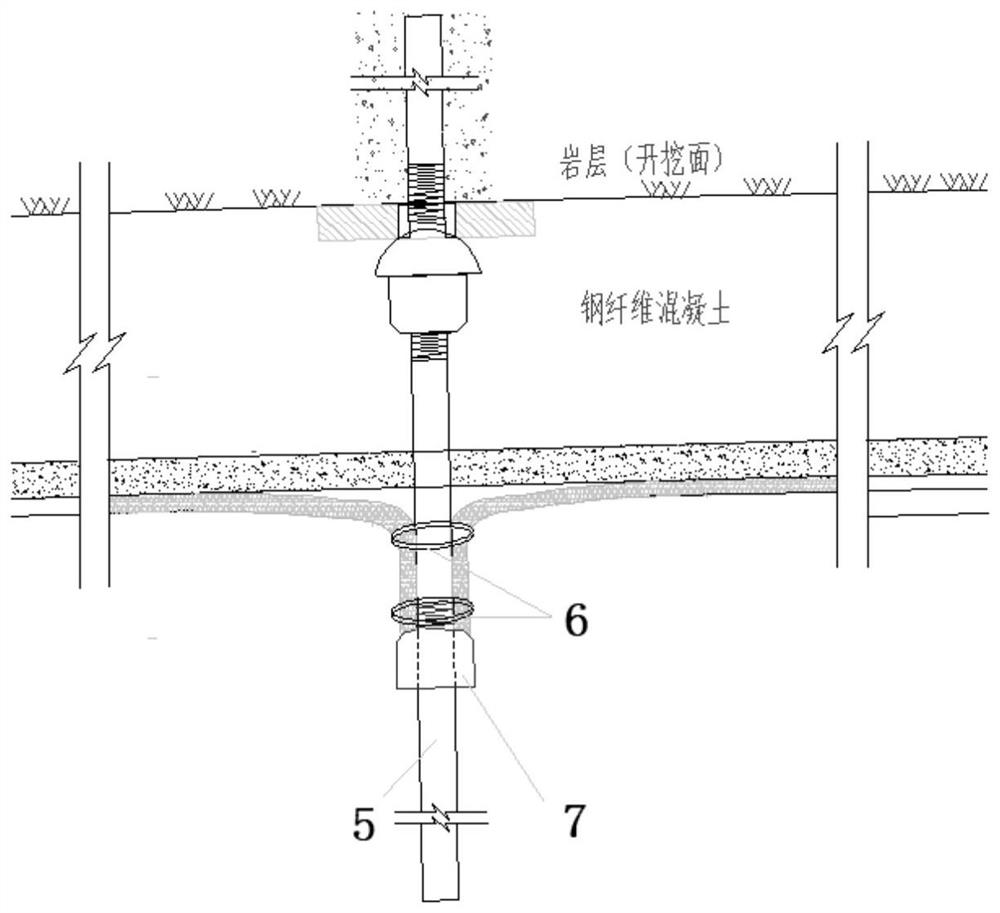

[0023] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

[0024] A node treatment method for anchor rods passing through the lining waterproof layer intensively in a large area, comprising the following steps:

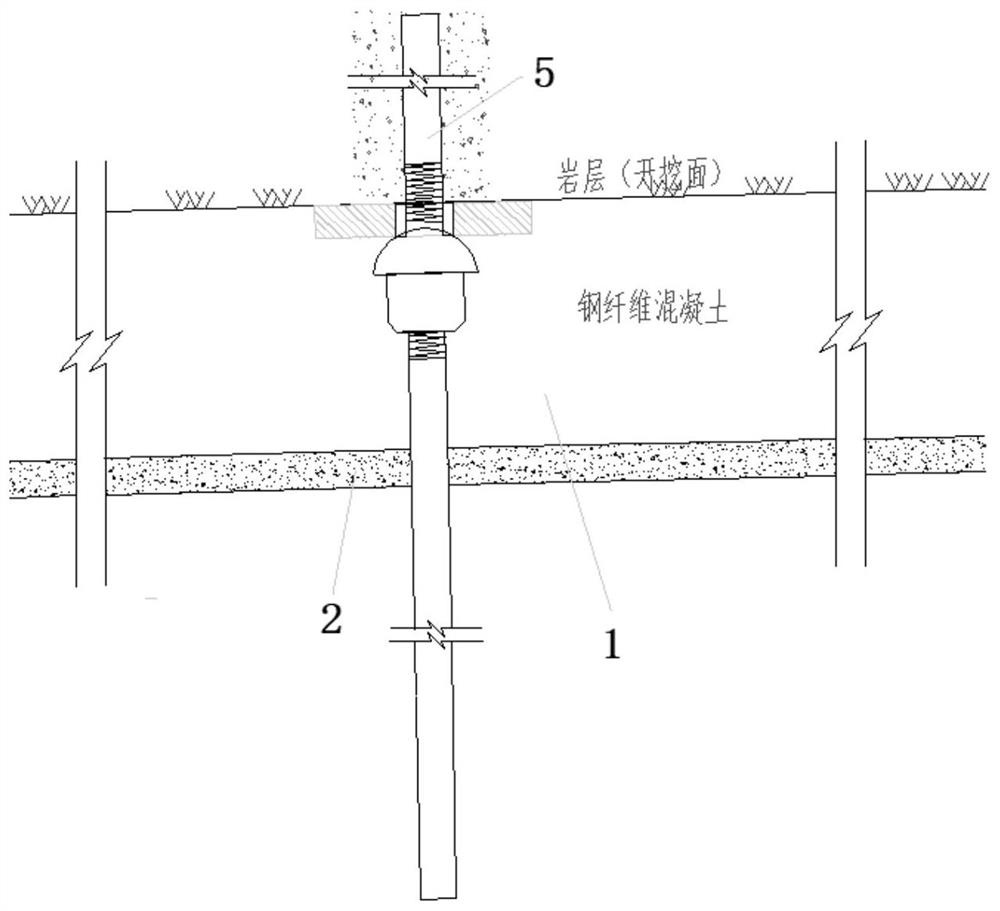

[0025] In the first step, after the tunnel is excavated and the steel fiber concrete is sprayed, the surface of the steel fiber concrete is leveled with mortar, and at the same time, the root pit of the exposed section of the anchor rod is leveled with mortar. Such as figure 1 As shown, a part of the anchor rod 5 rod body is driven into the rock body, and the anchor rod 5 rod body is exposed after passing through the sprayed reinforced concrete layer 1 (also called the initial supporting surface layer) and the mortar leveling layer 2.

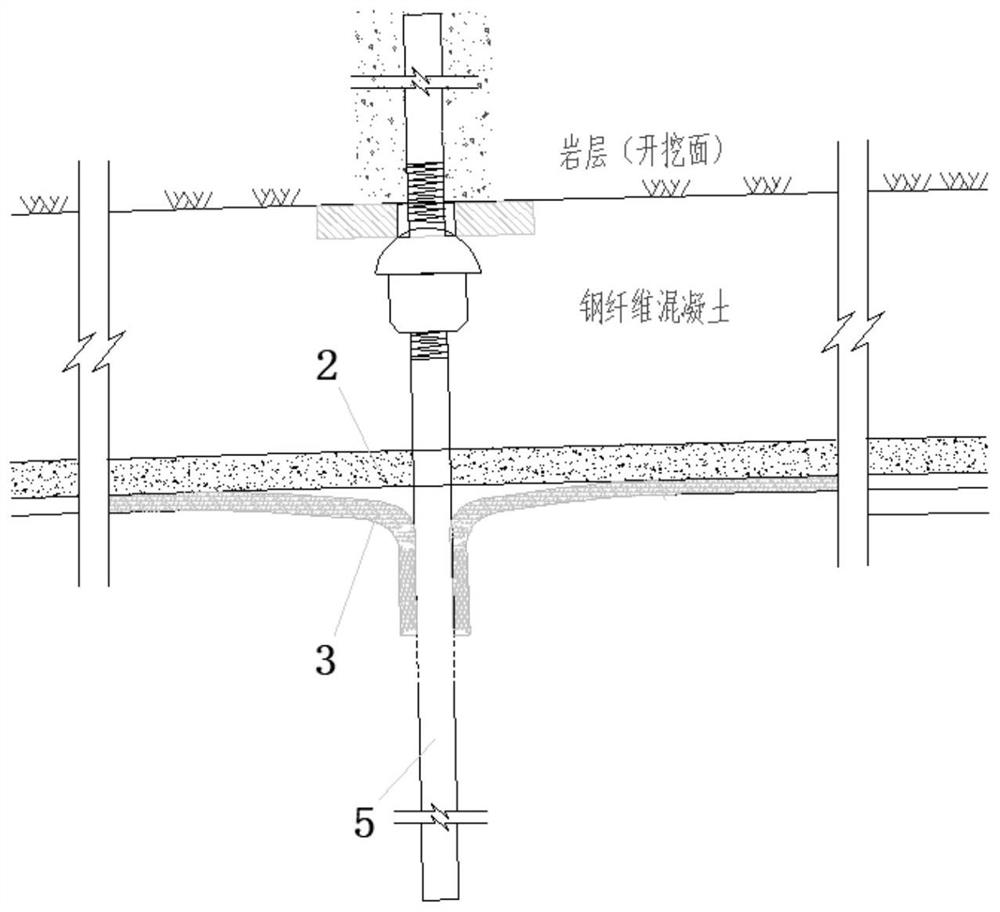

[0026] In the second step, a flexible waterproof material is laid outside the mortar screed layer 2, and a portion of the exposed section of the flexible waterproof mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com