Single-stage focusing spiral wave zone plate

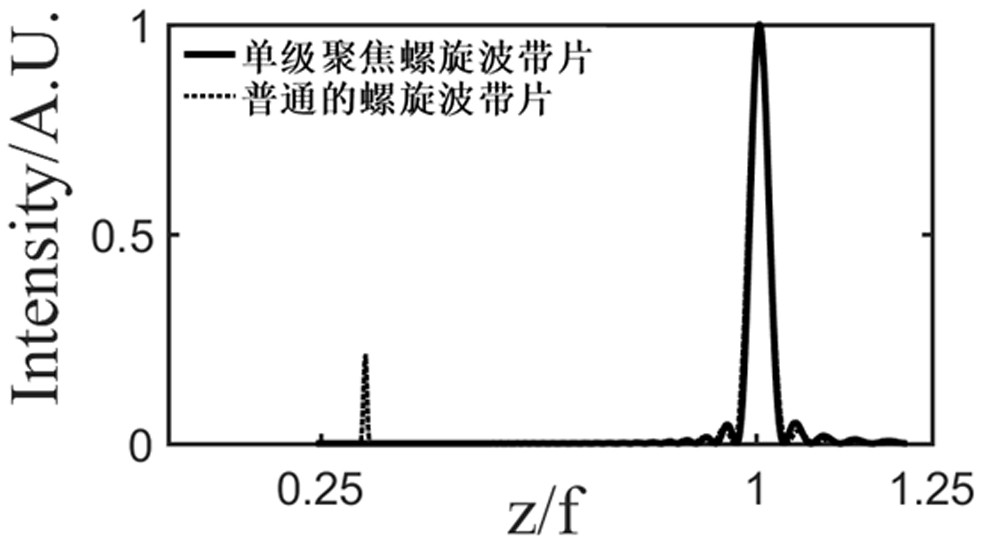

A helical wave and zone plate technology, which is applied in the field of single-stage focusing helical zone plate, can solve the problems of limiting the production accuracy of the zone plate, energy loss through the zone plate, and image quality degradation, etc., so that the production accuracy is easy to control , improved monochrome performance, and highly flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

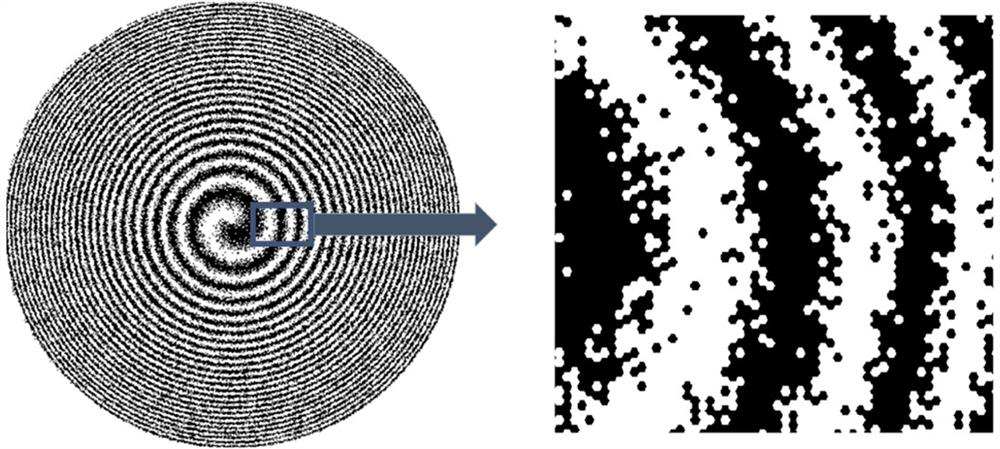

[0032] This embodiment discloses a single-stage focusing helical zone plate, refer to figure 1 and figure 2 As shown, it includes a silicon carbide transparent substrate and a plurality of tantalum (Ta) opaque elements formed on the silicon carbide transparent substrate.

[0033] In other embodiments, the material of the transparent substrate can also be ordinary glass or plexiglass light-transmitting material or one of silicon dioxide, silicon nitride and polyimide, and the opaque element can also be Chromium, gold (Au), aluminum, copper, nickel (Ni) or niobium, etc.

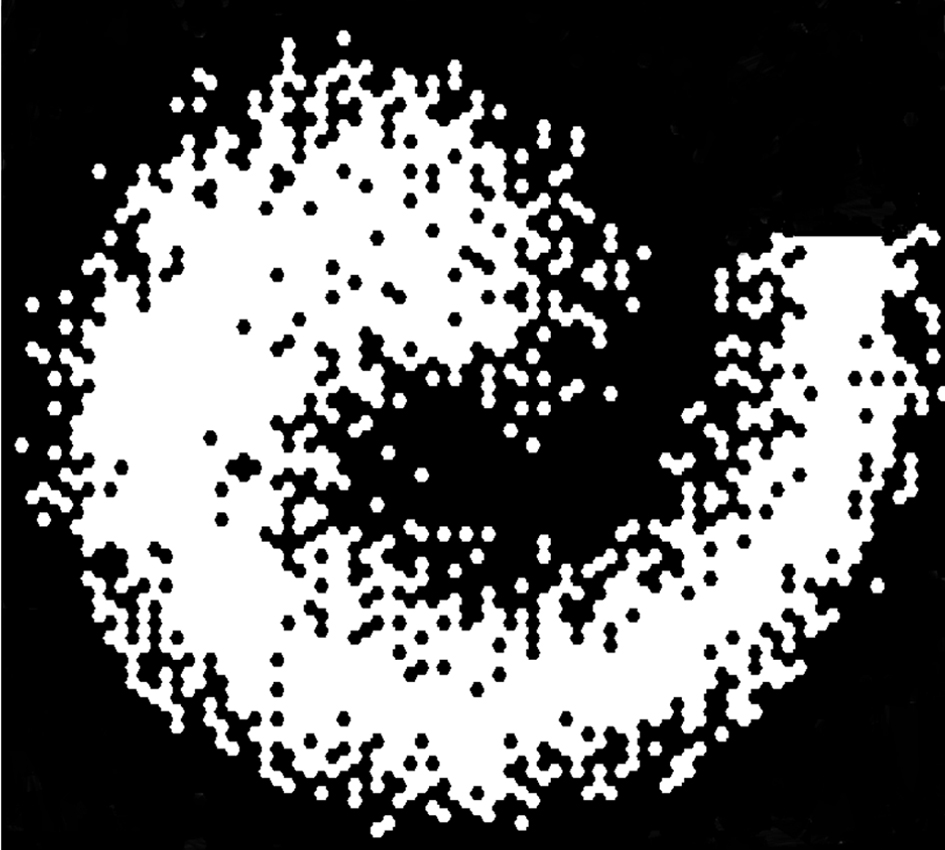

[0034] In this embodiment, the opaque primitives are regular hexagons with the same size, and may also be triangles, squares, or hexagons in other embodiments. like figure 1 Shown is the element distribution diagram of the first annular zone of the single-stage focusing helical zone plate of the present invention. If the regular hexagon filled with white is a light-transmitting element, the regular hexagon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com