Single stage focusing wave zone plate and manufacturing method thereof

A zone plate and single-stage technology, which is applied in the field of single-stage focusing zone plate and its manufacturing, can solve the problems of inability to manufacture suitable Gabor zone plate and limit the manufacturing precision of zone plate, and achieve the production accuracy, which is easy to control and improve Monochrome performance, flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] To this end, this embodiment discloses a single-stage focusing zone plate suitable for the visible light band, refer to figure 1 and figure 2 shown, including:

[0042] Transparent silicon carbide substrate;

[0043] Multiple tantalum (Ta) opaque primitives on a transparent substrate.

[0044] In the present invention, for visible light, the material of the transparent substrate can also be light-transmitting materials such as ordinary glass or plexiglass, and the opaque material can also be opaque metals such as gold, aluminum or copper.

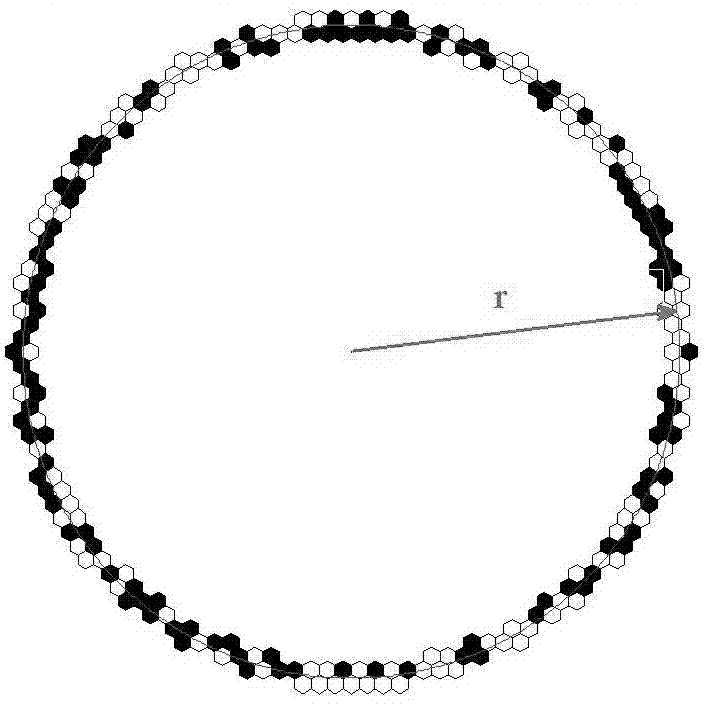

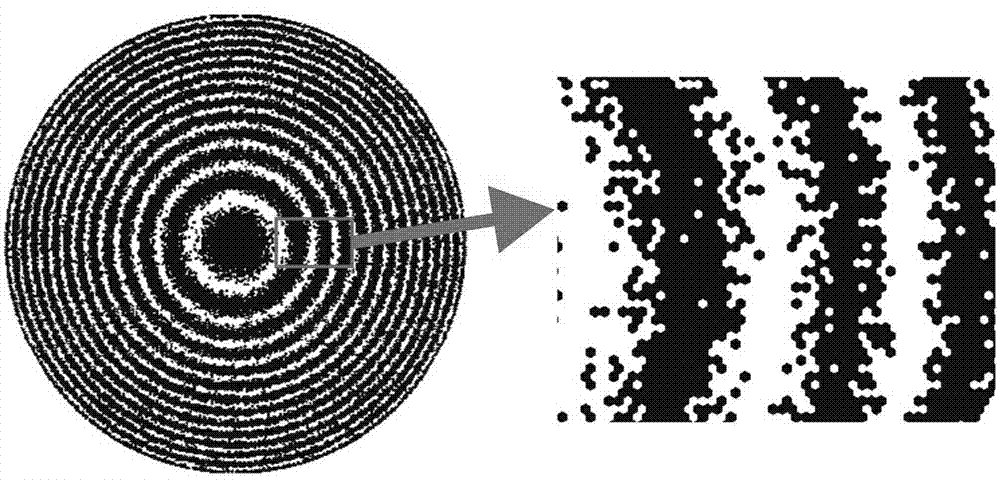

[0045] Wherein, the basic element may be tantalum (Ta), gold (Au), nickel (Ni) or other materials that can block electromagnetic waves of a certain band. The primitive can be one of polygons such as hexagon, circle, sector or other arbitrary shapes. Preferably, the primitive is a regular hexagon with the same size, such as figure 1 Shown is the single-stage focusing zone plate of the present invention at radius The distribut...

Embodiment 2

[0060] This embodiment discloses a single-stage focusing zone plate structure suitable for the THz band. The radius of the innermost ring of the single-stage focusing zone plate is 40mm, the width of the outermost ring is 2.8427mm, and the shape of the primitive is a regular hexagon (the The side length is 2mm), the ring number of the zone plate is 50, the total size of the single-stage focusing zone plate is 568 mm×568 mm; the wavelength of the incident light is 600 μm, so it can be seen that the corresponding focal length is m.

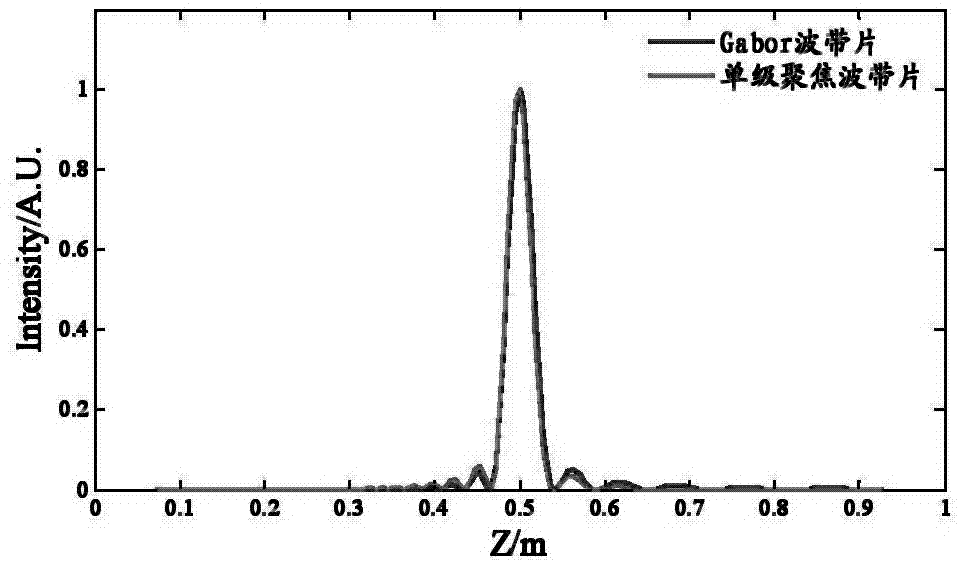

[0061] The structure of the single-stage focusing zone plate of the present invention has been described in detail above. In order to better understand the single-stage focusing effect of the present invention, the following will theoretically simulate the focusing characteristics of the single-stage focusing zone plate of the present invention. Refer to Figure 8 and Figure 9 shown. Figure 8 and Figure 9 are the diffracted light intensity di...

Embodiment 3

[0063] This embodiment discloses a single-stage focusing zone plate structure suitable for the soft X-ray band. The radius of the innermost ring of the single-stage focusing zone plate is 70 μm, the width of the outermost ring is 4.977 μm, and the shape of the primitive is a regular hexagon. (Its side length is 100nm), the number of zone plate rings is 50, the total size of the single-stage focusing zone plate is 990μm×990μm; the wavelength of the incident light is 6nm, so it can be seen that the corresponding focal length is cm.

[0064] The structure of the single-stage focusing zone plate of the present invention has been described in detail above. In order to better understand the single-stage focusing effect of the present invention, the following will theoretically simulate the focusing characteristics of the single-stage focusing zone plate of the present invention. Refer to Figure 10 and Figure 11 shown. Figure 10 and Figure 11 are the diffracted light intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com