Tubular tissue structure body and constructing method thereof

A construction method and structure technology, applied in the field of biomedical engineering, can solve problems such as low patency rate, customization and manufacturing, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

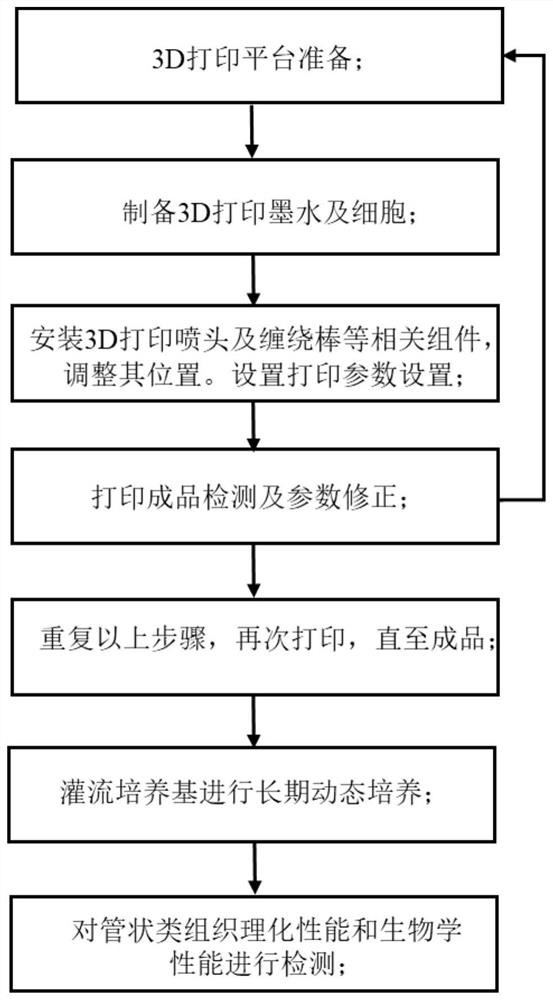

Method used

Image

Examples

Embodiment 1

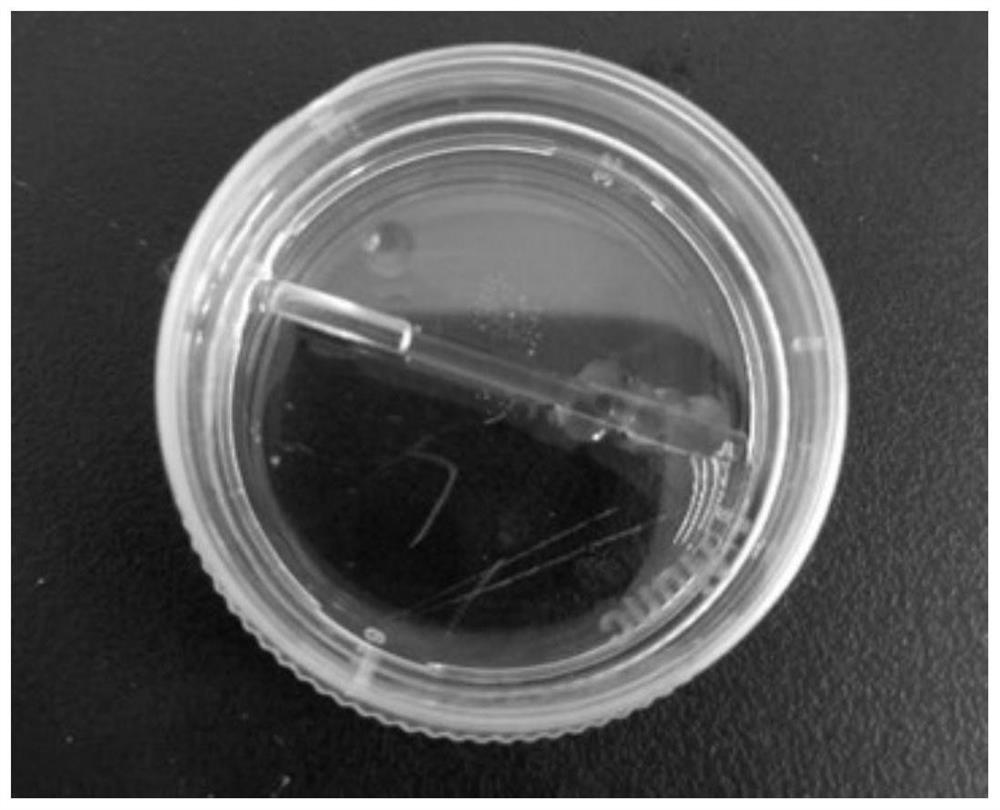

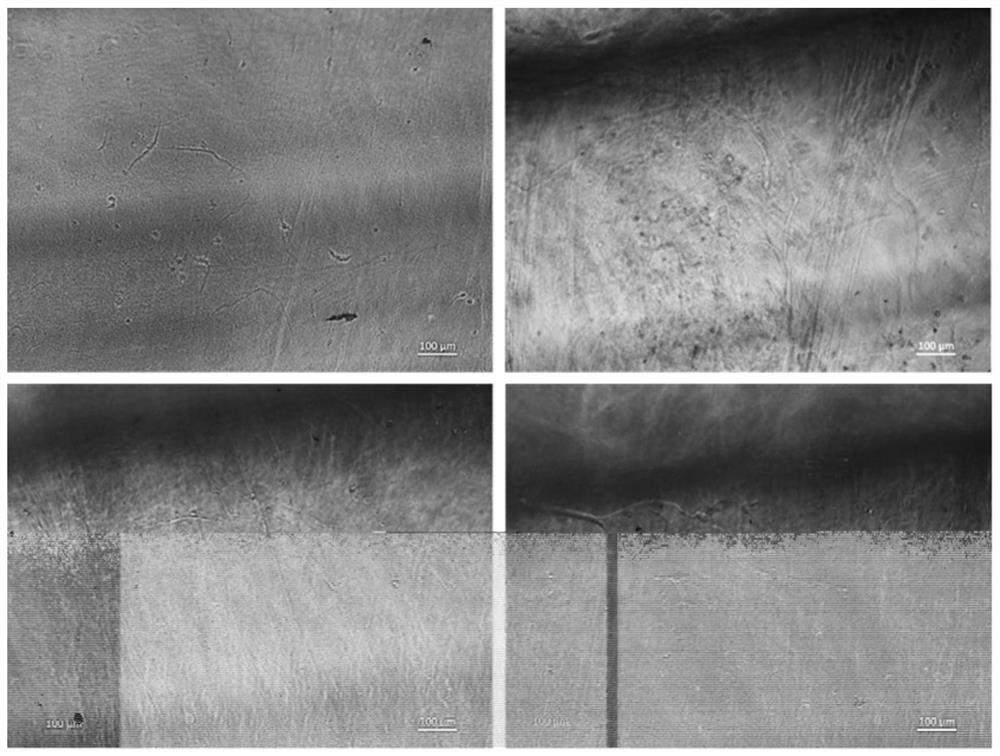

[0108] Example 1 Construction of Fibrin Tubular Vasculoid Structure

[0109] 1. Preparation of printing platform

[0110] Construct a stainless steel alloy frame structure, and assemble the 3D printing nozzle and winding rod in the frame, debug the motor control system, and build a motion system to ensure that the 3D printing nozzle can perform translational motion and the winding rod can perform rotational motion. During the installation process, ensure that the 3D printing nozzle is placed directly above the winding rod and in the same vertical plane as the winding rod. The winding rod is placed horizontally, and its rotational movement can be precisely controlled, while the translational direction of the 3D printing nozzle is along the axis of the winding rod, and its movement can also be precisely controlled. The platform structural parts are all customized from the enterprise, and a few parts such as motor mounting boards are obtained by purchasing raw materials such as ...

Embodiment 2

[0132] Example 2 Construction of fibrin tubular bile duct-like structure

[0133] 1. Preparation of printing platform

[0134] Construct a stainless steel alloy frame structure printing platform, mainly including printing nozzles and winding units for tubular construction. Among them, the printing platform and its components are independently drawn and designed, and each component can be customized by the enterprise or processed by a professional machining unit.

[0135] In this embodiment, a microfluidic chip nozzle designed based on the principle of microfluidics is used, and PMMA material is used to construct a microfluidic chip nozzle with a Y+S configuration flow channel. The nozzle can effectively promote solution fusion and prevent channel blockage problems.

[0136] The diameter of the glass tube used for winding in this embodiment is about 0.5 cm, which is close to the diameter of the human bile duct.

[0137] 2. Printing ink (bioprinting material) preparation

[...

Embodiment 3

[0161] Example 3 Construction of Tubular Bronchoid Structure

[0162] 1. Preparation of printing platform

[0163] Construct a stainless steel alloy frame structure printing platform, mainly including printing nozzles and winding units for tubular construction. Among them, the printing platform and its components are independently drawn and designed, and each component can be customized by the enterprise or processed by a professional machining unit.

[0164] In this embodiment, a microfluidic chip nozzle designed based on the microfluidic principle is used, and a PMMA material is used to construct a microfluidic chip nozzle with a single flow channel. The spray head can precisely control the solution flow.

[0165] The diameter of the glass tube used for winding in this embodiment is about 1 cm, which is similar to the diameter of the human bronchus.

[0166] 2. Printing ink (bioprinting material) preparation

[0167] The printing ink of the present invention can be purch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com