Returned material removing mechanism of construction waste environment-friendly ship loader

A technology of construction waste and ship loader, which is applied in the direction of cleaning device, transportation and packaging, loading/unloading, etc. It can solve problems such as difficult to achieve dust-free operation, silt ejection, and dust generation, so as to facilitate air injection and reduce impurities The effect of adhesion and reducing vibration reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

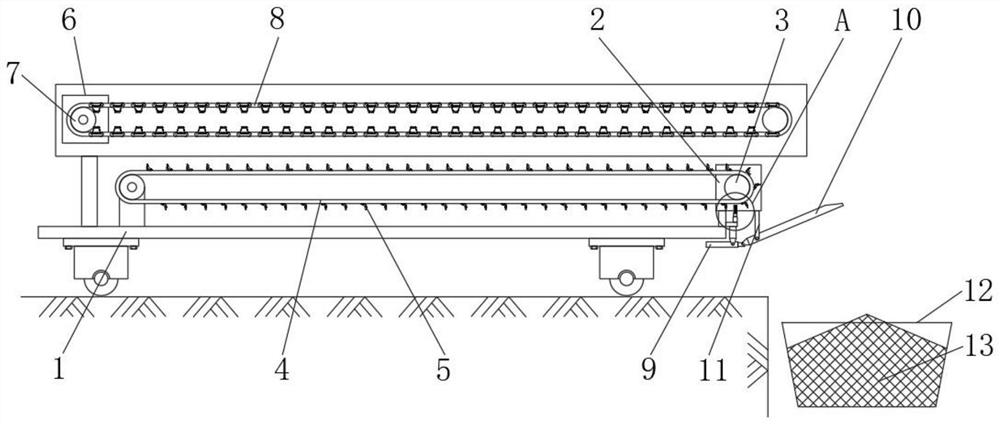

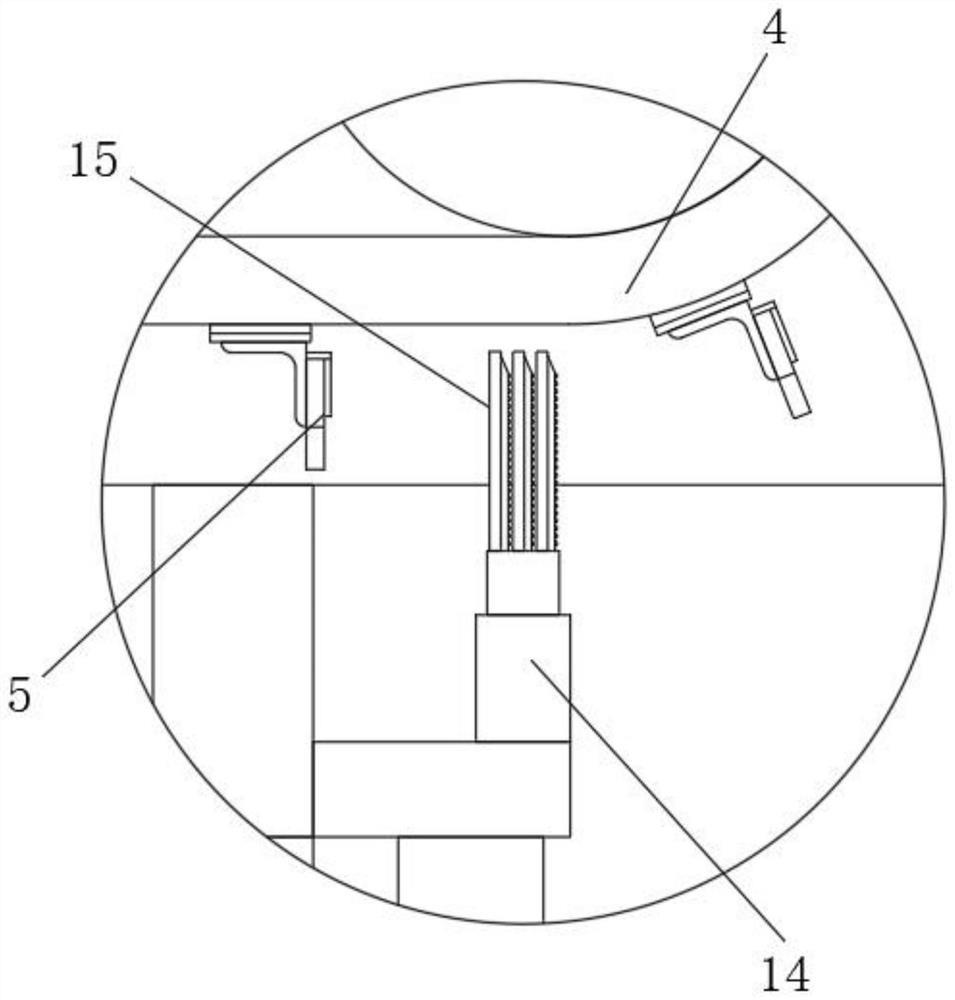

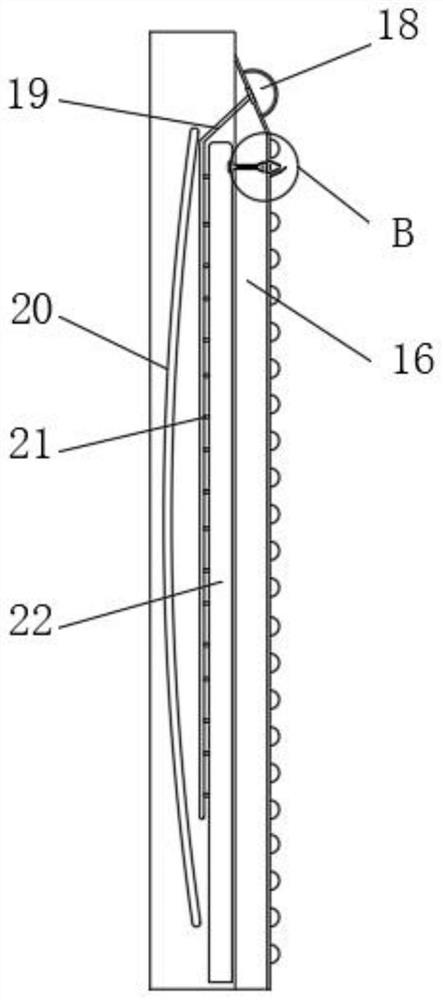

[0047]SeeFigure 1-6 , A construction waste environmental protection ship loader return material removal mechanism, including a movable frame 1, a first drive motor 2 is fixedly installed on the upper right side of the movable frame 1, and the output end of the first drive motor 2 is connected to the head wheel 3 and the nose The outer surface of the wheel 3 is connected with a return material removal chute 4, the outer surface of the return material removal chute 4 is fixedly installed with a slide plate 5, and the upper left side of the return material removal chute 4 is fixedly installed with a second drive motor 6 and a second drive motor 6 An active head 7 is connected to the output end of the active head 7, a chain conveyor 8 is fixedly installed on the outer surface of the active head 7, an electro-hydraulic push rod 9 is fixedly installed on the lower right side of the movable frame 1, and the output end of the electro-hydraulic push rod 9 is connected with The movable front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com