Water-based fluorescent ink as well as preparation method and application thereof

A fluorescent ink, water-based technology, applied in applications, chemical instruments and methods, inks, etc., can solve the problems of inability to achieve anti-counterfeiting encryption printing, short service life, low fluorescence intensity, etc., achieve excellent anti-counterfeiting ability, improve accuracy, and fluorescence intensity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

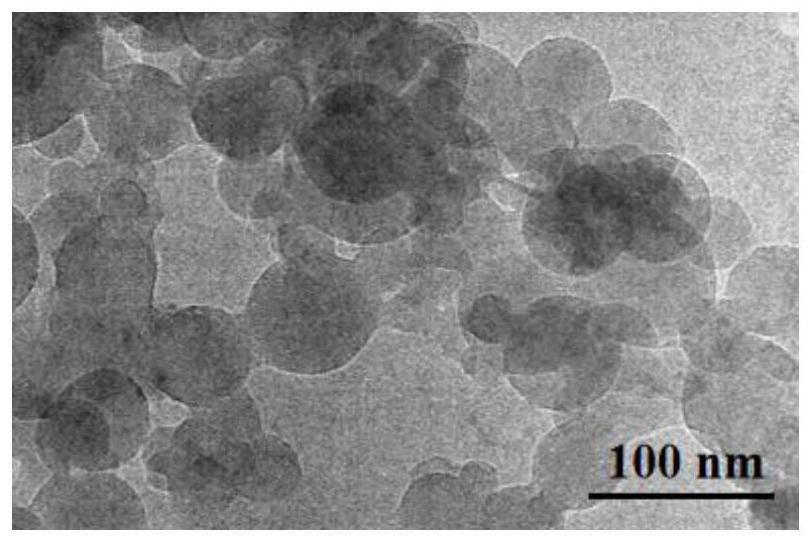

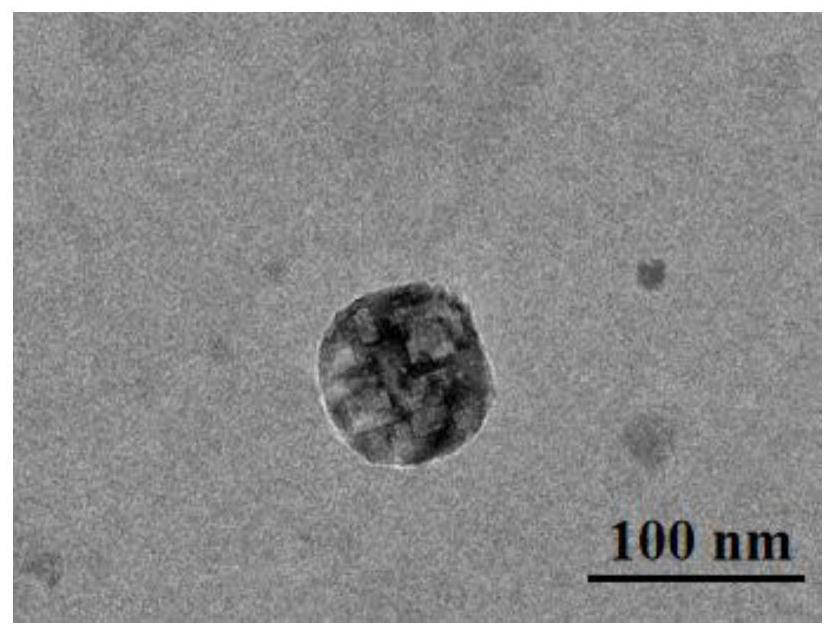

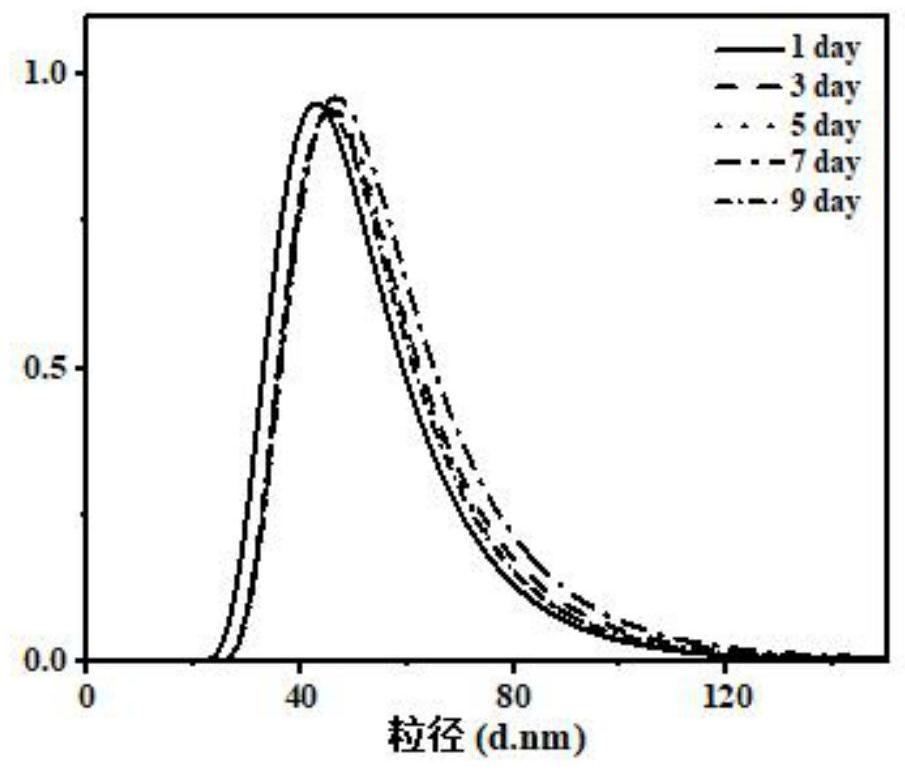

Image

Examples

preparation example Construction

[0045] The present invention also provides the preparation method of the water-based fluorescent ink described in the above technical scheme, comprising the following steps:

[0046] (1) mixing polystyrene microspheres with an organic solvent and a fluorescent dye to obtain a fluorescent solution;

[0047] (2) mixing the fluorescent solution obtained in the step (1) with a surfactant and water to obtain a homogeneous system;

[0048] (3) removing the organic solvent from the homogeneous system obtained in the step (2) to obtain a water-based fluorescent ink.

[0049] The invention mixes polystyrene microspheres with an organic solvent and a fluorescent dye to obtain a fluorescent solution.

[0050] In the present invention, the organic solvent is preferably toluene or benzene, more preferably toluene. In a preferred solution of the present invention, the toluene is less toxic.

[0051] In the present invention, the mass ratio of the polystyrene microspheres to the organic s...

Embodiment 1

[0066] In terms of mass content, the composition of the water-based fluorescent ink is: polystyrene microspheres 0.12%, fluorescent dye 0.012% (the mass content of PFO in the fluorescent dye is 100%, and the mass content of F8BT is 0%), sodium lauryl sulfate 0.5% % and water 99.368%.

[0067] M of PFO in this embodiment n 14311 Dalton, M w 19222 Daltons, MP 15292 Daltons, M z 25990 Daltons, M z+1 It is 34439 Daltons, and the polydispersity is 1.343157; the M of F8BT n 23064 Dalton, M w 48197 Daltons, MP 34516 Daltons, M z 108578 Dalton, M z+1 is 206211 Daltons with a polydispersity of 2.089722.

[0068] The preparation method of water-based fluorescent ink in the present embodiment is:

[0069] (1) 0.1g polystyrene microspheres were dissolved in 9.9g toluene, the mass ratio of polystyrene microspheres to toluene was 1:99, and 0.01g fluorescent dye (PFO) was added to obtain a fluorescent solution;

[0070] (2) Add 0.07 g of sodium lauryl sulfate to 14 g of water, then ...

Embodiment 2

[0073] PFO mass content is 99% (0.0099g) in the fluorescent dye, and F8BT mass content is 1% (0.0001g), and other is identical with embodiment 1, obtains water-based fluorescent ink S 3-2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com