A flexible piezoelectric polymer micromechanical energy harvester and its preparation method

A flexible piezoelectric and polymer technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., can solve the problems of low yield, poor piezoelectric performance, etc. The effect of increased capacitance and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

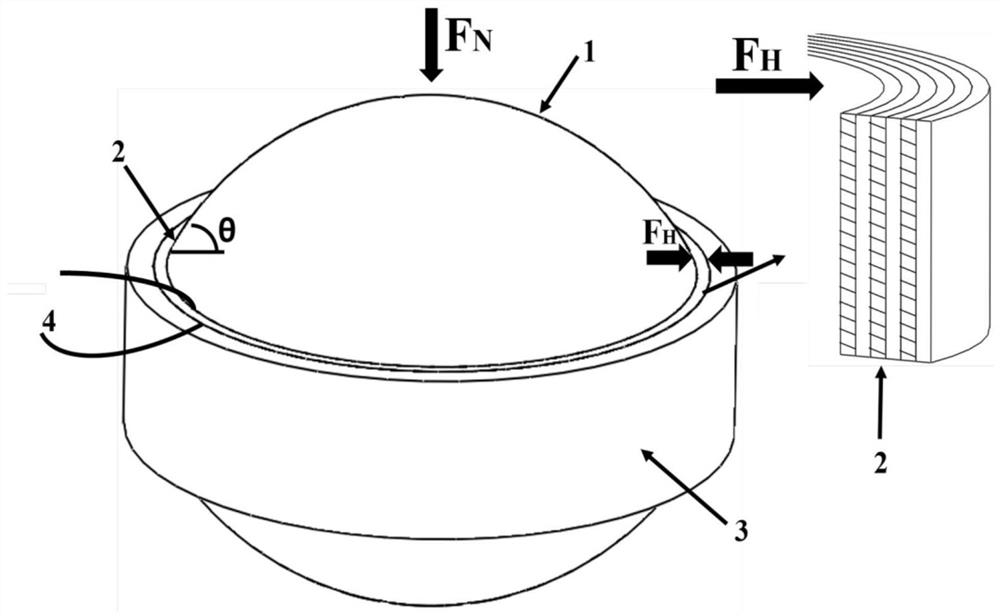

[0039] like figure 1As shown, the flexible piezoelectric polymer micromechanical energy harvester of this embodiment includes: a polymer elastomer 1, a multilayer piezoelectric film 2, parallel electrodes and a housing 3; wherein the polymer elastomer 1 is made of an elastic material, The upper surface and the lower surface are outwardly convex spherical surfaces; each layer of piezoelectric film includes an organic piezoelectric polymer film and a conductive film electrode, and the organic piezoelectric polymer film is made of organic polymer materials, and the shape is a length of Be the rectangle of b, the length a is greater than the side wall perimeter of the polymer elastomer, form a conductive film electrode on one surface of the organic piezoelectric polymer film, and carry out corona polarization, so that the galvanic couple of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com