A kind of micro-nano powder modified active solder and preparation method thereof

A technology of active solder and powder modification, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of uneven thickness of solder layer and thermal damage of diamond, achieve small strength loss and improved mechanical properties , The effect of improving processing efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

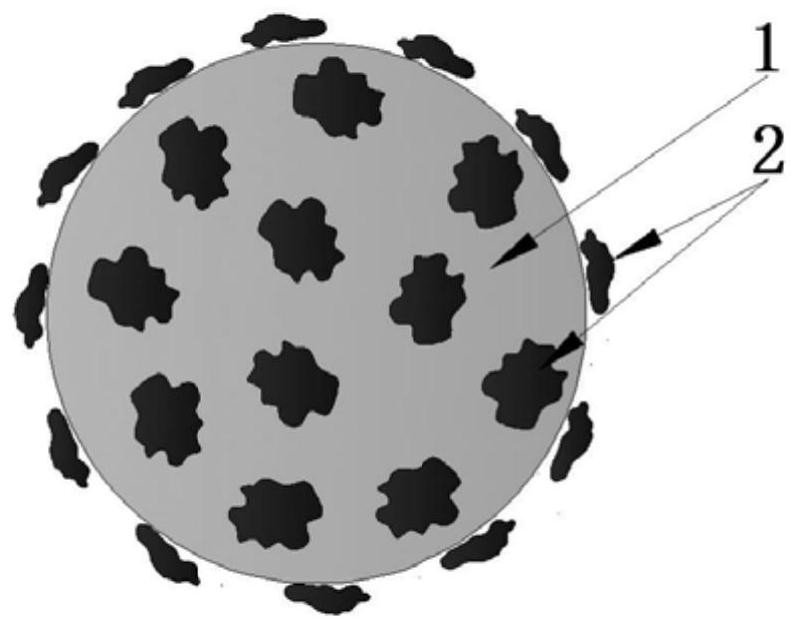

[0034] A method for preparing active solder modified by micro-nano powder, comprising the following steps:

[0035] Step 1), taking 80-99 parts of the solder body and 1-10 parts of the micro-nano powder according to the parts by mass;

[0036] Take 1-2 parts when the micro-nano powder uses defective graphene; take 5-10 parts when the micro-nano powder uses Cu-Ce alloy, take 4-8 parts when the micro-nano powder uses TiC powder, and use Take 1-10 parts of the composite powder of defective graphene and Cu-Ce alloy; the brazing filler metal body adopts Ni-Cr alloy brazing filler metal or Cu-Sn-Ti alloy brazing filler metal;

[0037] Step 2), ball milling the micro-nano powder to make the particle size less than 20 μm;

[0038] Specifically, when the micro-nano powder uses defective graphene, the particle size is less than 20 μm after ball milling, and structural defects appear in more than 50% of the defective graphene area; when the micro-nano powder uses Cu–Ce alloy, the partic...

Embodiment 1

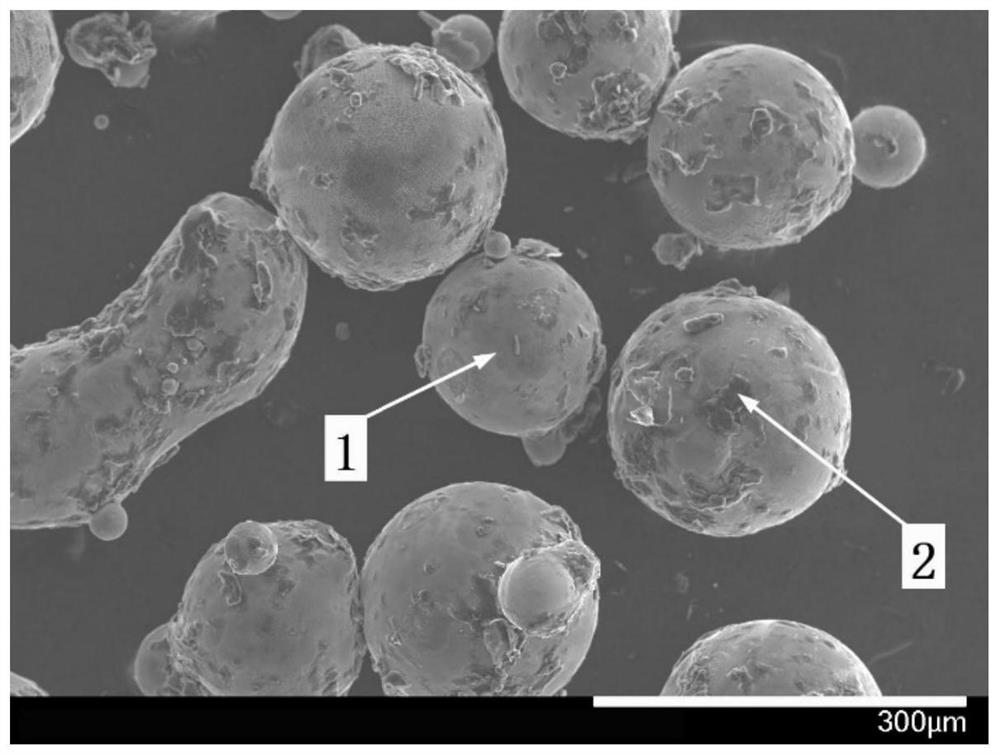

[0057] Step 1), taking 90 parts of Ni-Cr alloy solder and 8 parts of Cu-Ce alloy according to the mass parts;

[0058] Step 2), the Cu-Ce alloy is ball milled to make the particle size less than 20 μm, the vibration frequency of the vibratory ball mill is 30 Hz, the working amplitude is 7 mm, the speed of the ball mill is 30 r / min, the vibration ball milling time is 3 h, the ball-to-material ratio is 1:1, the ball The total volume of powder and powder is 80% of the volume of the ball mill tank, and the ball mill tank and balls are made of wear-resistant ceramic materials;

[0059] Step 3), using dimethylamide to completely disperse and dissolve the Cu-Ce alloy after ball milling to obtain a mixed solution A, the weight ratio of dimethylamide to Cu-Ce alloy is 1:10;

[0060] Step 4), mix the mixed solution A in the dispersant solution evenly, then add the Ni-Cr alloy solder to fully mix and evenly dry, and then obtain the active solder modified by micro-nano powder; in the disp...

Embodiment 2

[0062] Step 1), taking 80 parts of Ni-Cr alloy solder and 10 parts of Cu-Ce alloy according to the mass parts;

[0063] Step 2), the Cu-Ce alloy is ball milled, the vibration frequency of the vibration ball mill is 10Hz, the working amplitude is 10mm, the speed of the ball mill is 20r / min, the vibration ball milling time is 6h, the ball-to-material ratio is 1:2, and the total volume of the ball and powder is 75% of the volume of the ball mill, the ball mill and the ball are made of wear-resistant ceramics;

[0064] Step 3), using liquid paraffin to completely disperse and dissolve the ball-milled Cu-Ce alloy to obtain mixed solution A, the weight ratio of liquid paraffin to Cu-Ce alloy is 1:10;

[0065] Step 4), mix the mixed solution A in the dispersant solution evenly, then add the Ni-Cr alloy solder to fully mix and evenly dry, and then obtain the active solder modified by micro-nano powder; in the dispersant solution The dispersant is sodium lauryl sulfate, the weight rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com