A dry stone granule and rock slab with simulation effect and its preparation method and application

A stone and dry particle technology, applied in the field of brick product coatings, can solve the problems of high initial melting point and high temperature viscosity stone dry particles, insufficient three-dimensional effect, no flash effect, etc., achieve high and high temperature viscosity, low cost of raw materials, and reduce viscosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

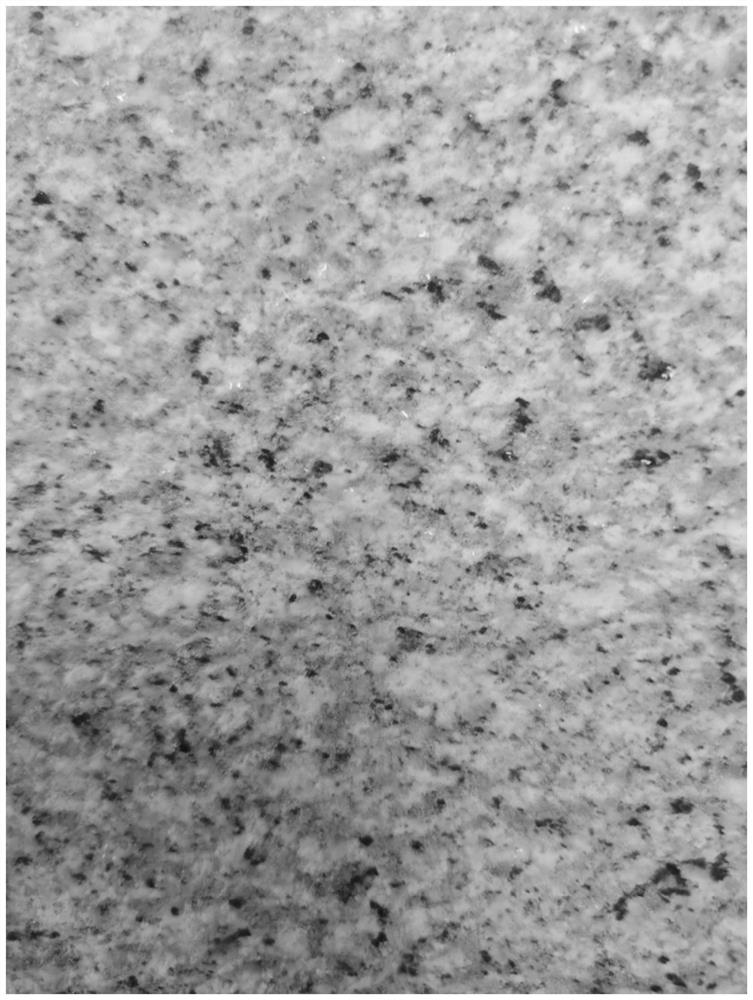

[0030] Embodiment 1 has the preparation of stone material dry granule and slate of simulation effect

[0031] The preparation steps of stone dry granules with simulation effect are as follows:

[0032] Take 50Kg of potassium feldspar, 10Kg of quartz, 6Kg of zinc oxide, 5Kg of calcite, 7Kg of dolomite, 12Kg of barium carbonate, 3Kg of boronite, 4Kg of cerium oxide and 3Kg of alumina. The obtained frit is pulverized by a jet mill to obtain granular dry stone granules with a particle size of 30-150 meshes, which is recorded as the finished product 1 of the embodiment of dry stone granules with simulation effect.

[0033] The steps to prepare the rock slabs are as follows: apply the finished product 1 of dry stone granules with simulation effect on the brick surface that has been glazed with a bell jar, and then fire at 1200°C for 55 minutes to obtain a rock slab. Example finished product 1.

Embodiment 2

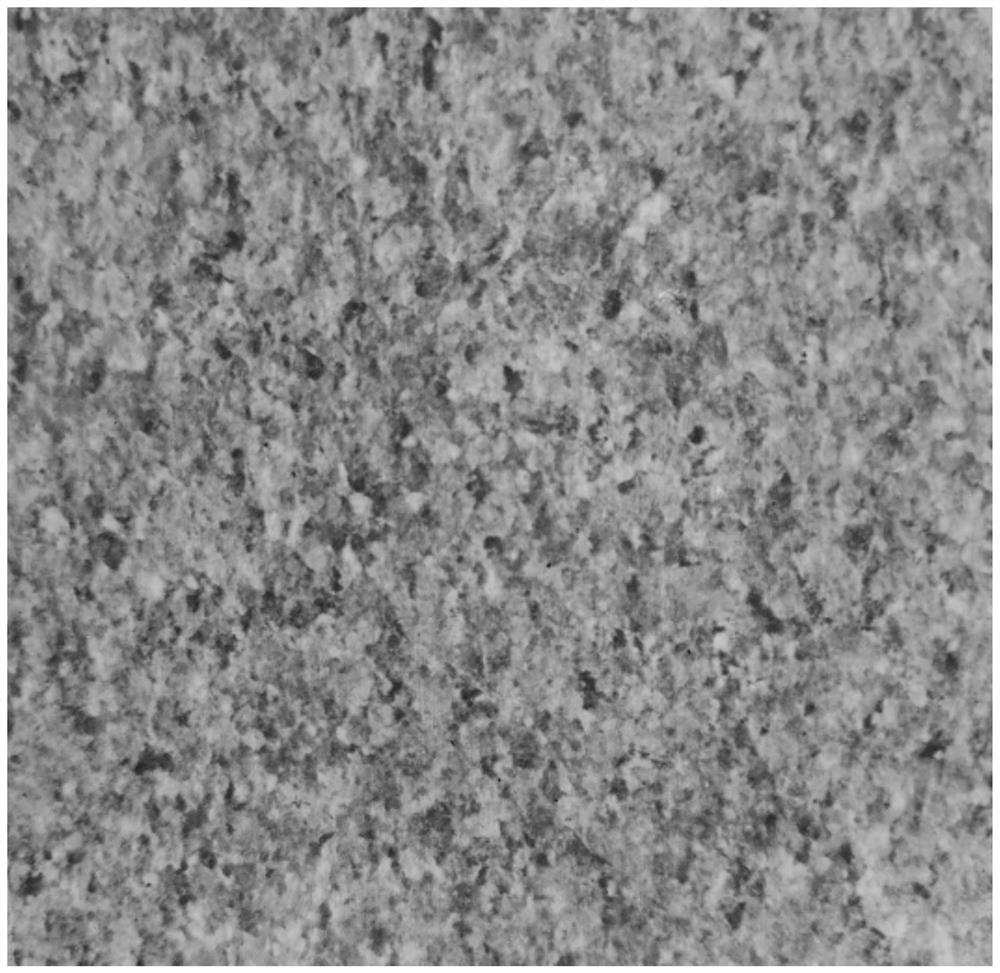

[0034] Embodiment 2 has the preparation of stone material dry granule and slate of simulation effect

[0035] The preparation steps of stone dry granules with simulation effect are as follows:

[0036] Take 50Kg of potassium feldspar, 10Kg of quartz, 6Kg of zinc oxide, 4Kg of calcite, 6Kg of dolomite, 12Kg of barium carbonate, 3Kg of boronite, 5Kg of cerium oxide and 4Kg of alumina. The obtained frit is pulverized by a jet mill to obtain granular dry stone granules with a particle size of 30-150 meshes, which is recorded as the finished product 2 of the embodiment of dry stone granules with simulation effect.

[0037] The steps for preparing the slate are as follows: apply the finished product 2 of the stone dry granule example 2 with the simulation effect on the brick surface that has been glazed with a bell jar, and then fire it at 1200°C for 55 minutes to obtain a slate. Example finished product 2.

Embodiment 3

[0038] Embodiment 3 has the preparation of stone dry granule and slate with simulation effect

[0039] The preparation steps of stone dry granules with simulation effect are as follows:

[0040] Take 50Kg of potassium feldspar, 11Kg of quartz, 6Kg of zinc oxide, 6Kg of calcite, 7Kg of dolomite, 12Kg of barium carbonate, 3Kg of boronite, 3Kg of cerium oxide and 2Kg of aluminum oxide, mix well, and melt at 1450°C for 5.5 hours. The obtained frit was pulverized by a jet mill to obtain granular stone dry granules with a particle size of 30-150 meshes, which was recorded as Example 3 of dry stone granules with simulation effect.

[0041] The steps for preparing the slate are as follows: apply the finished product 3 of the stone dry granule example 3 with the simulation effect on the brick surface that has been glazed with a bell jar, and then fire it at 1200°C for 55 minutes to obtain a slate. Example finished product 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com