Radiation protection composite material as well as preparation method and application thereof

A composite material and anti-radiation technology, applied in the field of anti-radiation, can solve problems such as poor softness, uniformity, and anti-radiation properties, unsatisfactory, thick gloves, etc., to achieve reduced surgical operations, protection against damage, excellent softness and stretching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

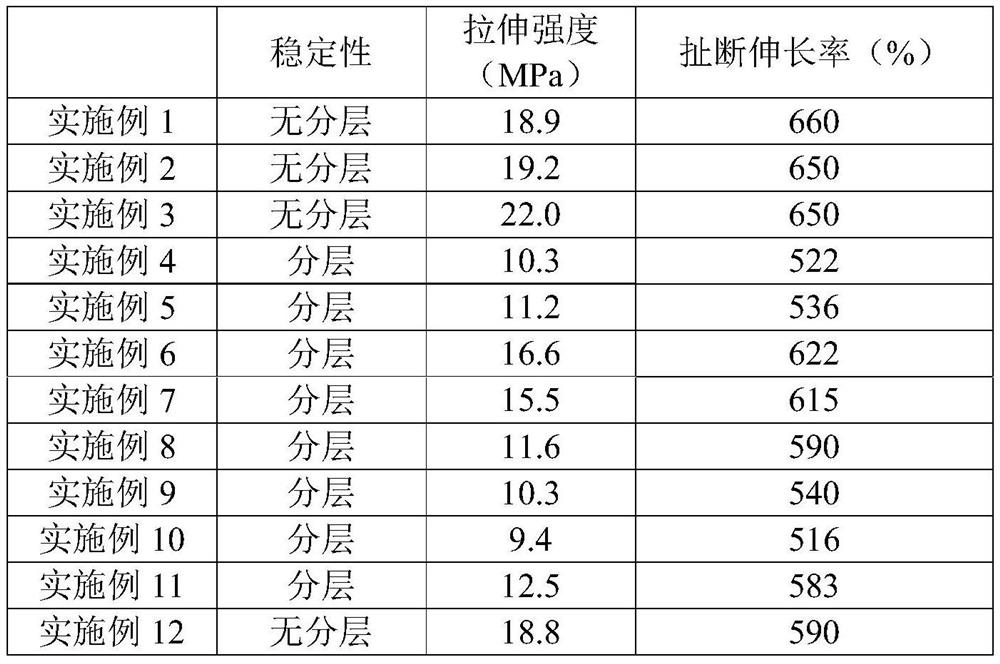

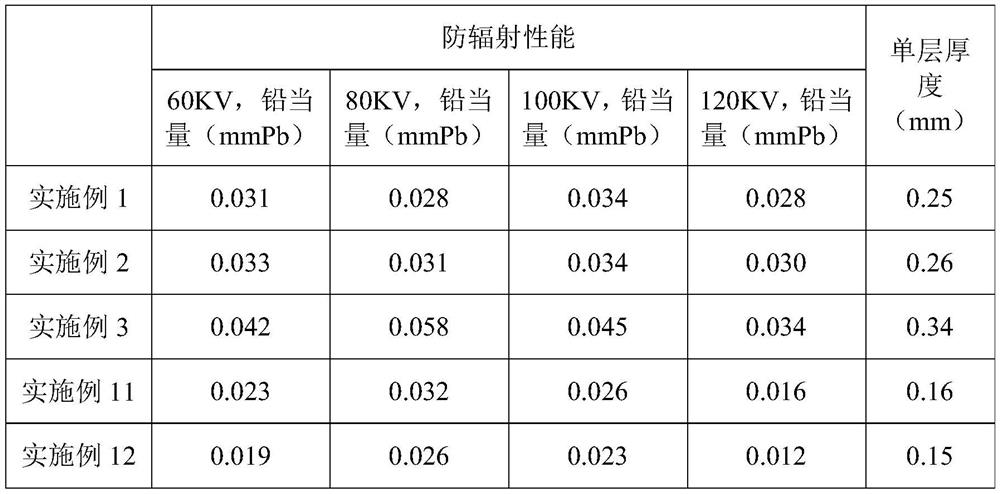

Examples

preparation example Construction

[0053] A second aspect of the present invention provides a method for preparing the radiation-resistant composite material, which includes the following steps:

[0054] (1) Mix bismuth trioxide, filler and polyacrylate, and grind to obtain radiation shielding filler slurry;

[0055] (2) adding the radiation shielding filler slurry into the liquid rubber, stirring to obtain a mixed emulsion;

[0056] (3) Dipping and molding the mixed emulsion to obtain the product.

[0057] In one embodiment, the grinding is dry grinding and / or wet grinding.

[0058] Preferably, the grinding is wet grinding.

[0059] In one embodiment, the grinding time of the grinding is greater than 8 hours.

[0060] In the step (1) of the present application, grind until the color distribution is uniform and the radiation shielding filler slurry can be well dispersed when stirred in the step (2), that is, the grinding is completed.

[0061] The third aspect of the present invention provides an applicatio...

Embodiment 1

[0082] Embodiment 1 of the present invention provides a radiation-shielding composite material, and its preparation raw materials are 100 parts of radiation-shielding filler slurry and 100 parts of liquid rubber in parts by weight.

[0083] The raw materials for preparing the radiation shielding filler slurry are bismuth trioxide, filler and polyacrylate, and the weight ratio thereof is 33:1:1. The bismuth trioxide has a particle size of 300nm, the filler is titanium dioxide with a particle size of 300nm, and the polyacrylate is sodium polyacrylate, purchased from Zhengzhou Guanda Chemical Products Co., Ltd.

[0084] The liquid rubber is natural latex, purchased from Jinan Deqiao Chemical Technology Co., Ltd.

[0085] The preparation method of the radiation protection composite material is as follows:

[0086] (1) Mix bismuth trioxide, filler and polyacrylate, and perform wet grinding for 9 hours to obtain a radiation shielding filler slurry;

[0087] (2) adding the radiatio...

Embodiment 2

[0096] Embodiment 2 of the present invention provides a radiation-shielding composite material, and its preparation raw materials are 120 parts of radiation-shielding filler slurry and 100 parts of liquid rubber in parts by weight.

[0097] The raw materials for preparing the radiation shielding filler slurry are bismuth trioxide, filler and polyacrylate, and the weight ratio thereof is 30:1:1. The bismuth trioxide has a particle size of 600nm, the filler is titanium dioxide with a particle size of 300nm, and the polyacrylate is sodium polyacrylate, purchased from Zhengzhou Guanda Chemical Products Co., Ltd.

[0098] The liquid rubber is natural latex, purchased from Jinan Deqiao Chemical Technology Co., Ltd.

[0099] The preparation method of the radiation protection composite material is as follows:

[0100] (1) Mix bismuth trioxide, filler and polyacrylate, and perform wet grinding for 9 hours to obtain a radiation shielding filler slurry;

[0101] (2) adding the radiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com