Preparation method of integrally-woven friction material

A technology of integral weaving and friction materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of white smoke, difficult drilling, scratching the dual surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of the present invention relates to a method for preparing an integral braided friction material, comprising the following steps:

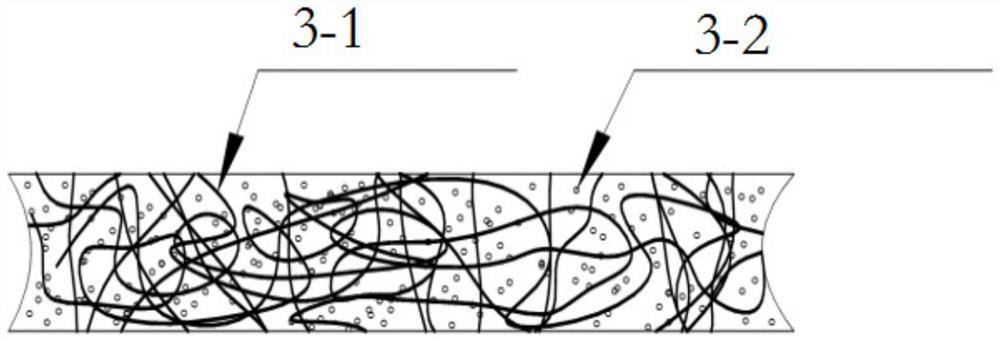

[0038] 1) Preparing ply yarns: plying metal fibers, inorganic fibers and / or organic fibers to make ply yarns;

[0039] In one embodiment of the present invention, the metal fiber is selected from at least one of copper wire, zinc wire, and silver wire; the inorganic fiber is glass fiber and / or basalt fiber; the organic fiber is selected from polyester, At least one of acrylic fiber, nylon fiber, polypropylene fiber, aramid fiber and cotton thread.

[0040] Among the above-mentioned fibers, the metal fiber has good thermal conductivity and has a certain hardness as a supporting material. It is required that the hardness of the metal should not be too high, otherwise it cannot be plied with other fibers. Inorganic fibers have good heat resistance, mechanical properties and wear resistance. Polymer organic fibers such as arami...

Embodiment 1

[0055] An integral braided friction material, the preparation method of which comprises the following steps:

[0056] 1) Preparation of plied wire: 20 parts of copper wire, 50 parts of glass fiber and 30 parts of cotton thread are plied to make a plied wire;

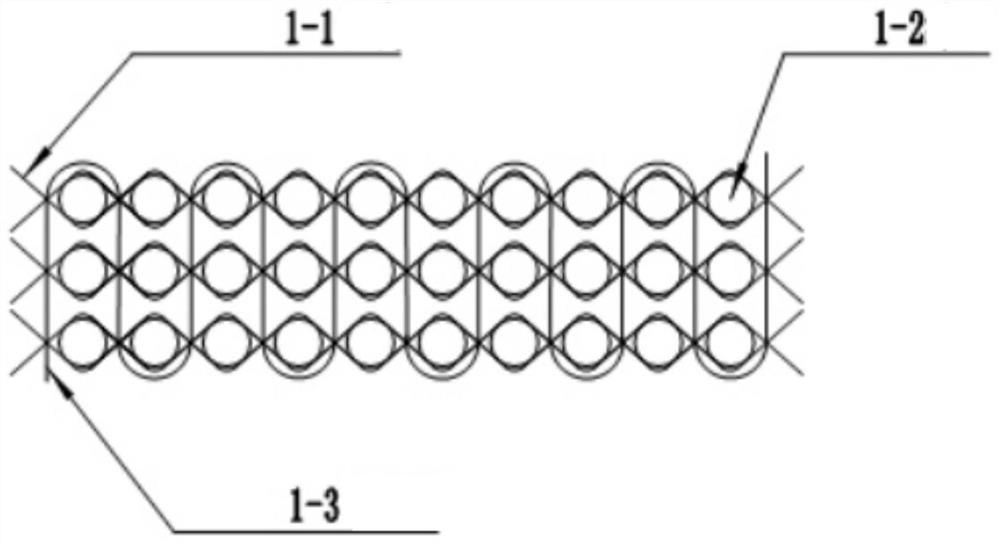

[0057] 2) Preparation of woven cloth: using a braiding machine and a half-cross integral weaving method, the ply yarn prepared in step 1) is made into a woven cloth with a density of 1.2 g / cm 3 ;

[0058] 3) Resin impregnation: immerse the woven fabric prepared in step 2) into liquid phenolic resin for 60 minutes, take it out and wait for the resin to dry naturally, then place it in an oven and dry at 120°C for 50 minutes to obtain a green body;

[0059] 4) Hot press curing: according to the size of the clutch disc, cut the green body prepared in step 3) into the desired shape, and then place it in a hot press mold for hot press curing. The temperature of hot press curing is 130°C and the pressure is 13MPa , the time i...

Embodiment 6

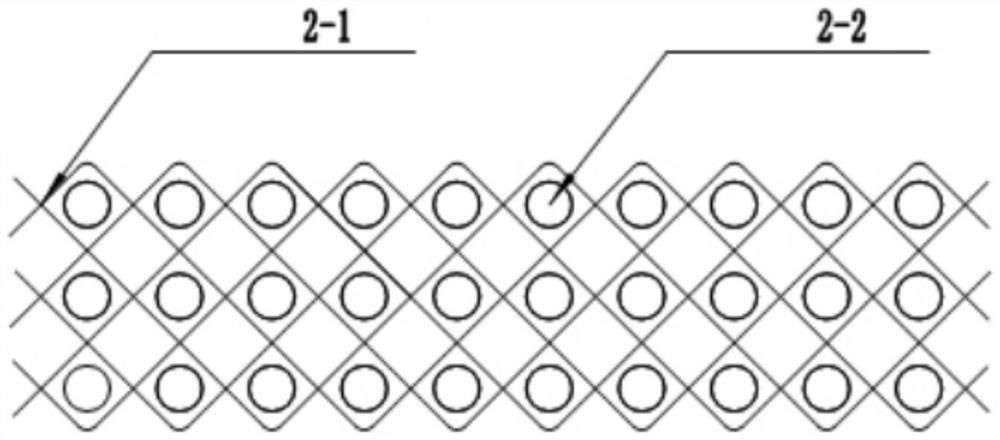

[0075] Compared with Example 1, Example 6 has similar mechanical properties, only the coefficient of friction is slightly lower than Example 1, which shows that the weaving method has a certain influence on the temperature resistance of the friction material. The friction material of Example 6 adopts the full-intersection integral weaving method, and the heat conduction distance of the upper and lower sides is longer than that of the friction material obtained by the half-intersection integral weaving method in Example 1, the heat dissipation is worse, and the friction coefficient is slightly reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com