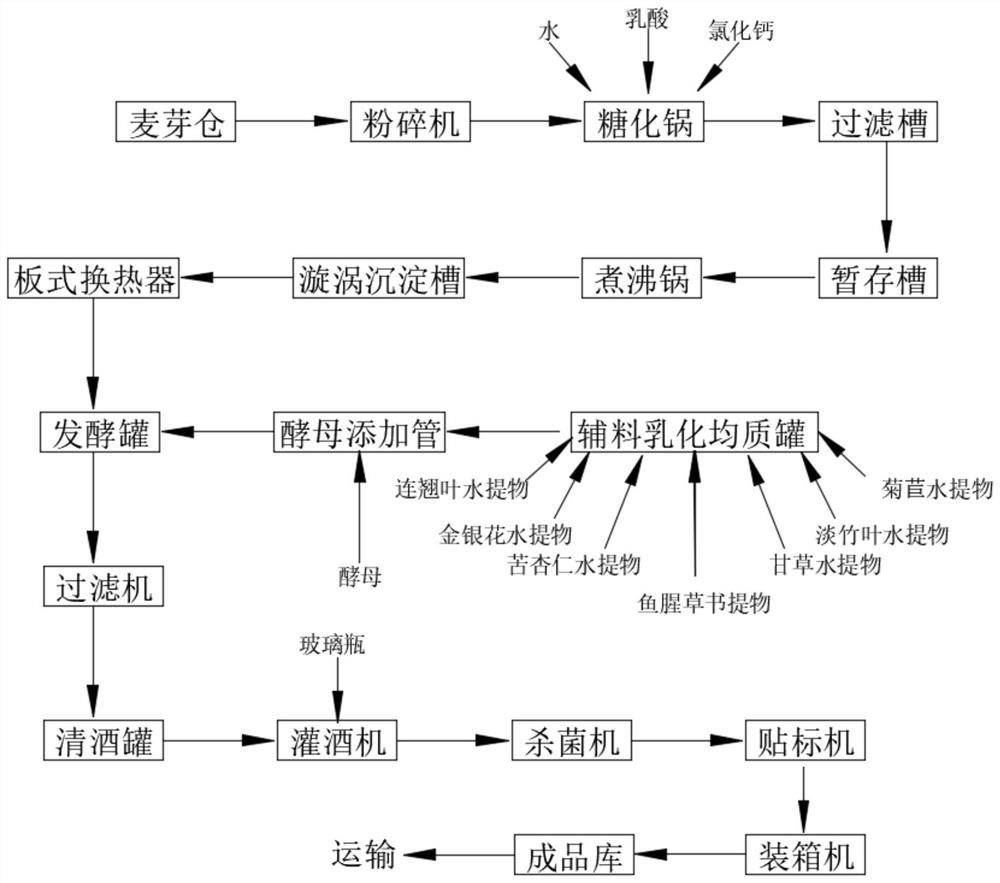

Lotus craft beer brewing process and flow

A technological process and beer technology, applied in the field of beer, can solve problems such as inefficiency and physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A lotus craft beer, which is made of Australian malt, caramel malt, forsythia leaf water extract, honeysuckle water extract, bitter almond water extract, Houttuynia cordata water extract, licorice water extract, The water extract of bamboo leaves, water extract of chicory, purified water and additives are mixed, brewed by saccharification, fermentation, filtration and sterilization;

[0068] The weight ratio of each component in Lotus Craft Beer is: 440 kg of Australian malt and 10 kg of caramel malt.

[0069] As a further solution of the present invention: additives include lactic acid 150g, calcium chloride 400g and zinc sulfate 0.3g.

[0070] As a further solution of the present invention: the ratio of malt to water in the mash tun is 1 to 3.6.

[0071] As a further solution of the present invention: the water weight ratio of the saccharification pot is: 1400 kg of brewing water and 200 kg of pretreated water.

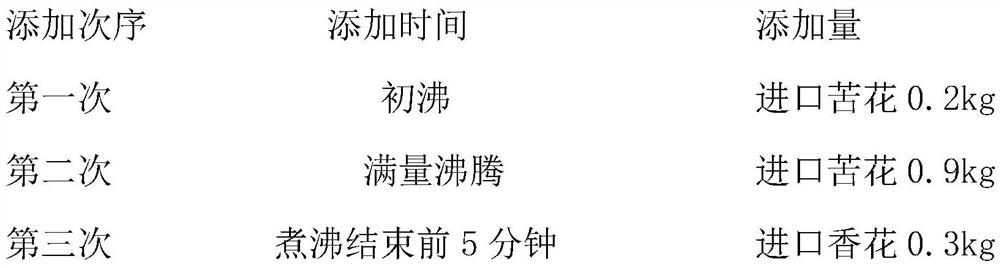

[0072] As a further solution of the present invention...

Embodiment 2- Embodiment 6

[0103] Below is embodiment 2-embodiment 6, and its preparation method is identical with embodiment 1, only there is the adjustment (unit part) of part component content:

[0104]

[0105] Some beers are made by embodiment 1-embodiment 6, and every group of embodiment extracts 10 beers and carries out following test as a group:

[0106] Determination of original wort concentration: automatic beer component analyzer;

[0107] Alcohol determination: automatic beer composition analyzer;

[0108] Aroma and taste test: Randomly select a number of people to try the beer, and record it according to the testers' comments (the aroma and taste are compared with ordinary beer).

[0109] The measurement results are as follows:

[0110]

[0111]

[0112] It can be seen from the above table that the taste of beer is the best when the water extract of forsythia leaf is 2 parts, the water extract of honeysuckle is 5 parts, and the water extract of bitter almond is 3 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com