Device and method for carrying out acidolysis by adopting I-type glass tube

A glass tube and acid hydrolysis technology, which is applied in the field of devices and methods for acid hydrolysis using type I glass tubes, can solve the problems of increasing the experiment error rate, the energy consumption of experimenters, prolonging the experimental steps and time, and increasing the risk of operational errors, etc. Achieve the effect of reducing the risk of experimental errors, reducing manufacturing costs, and convenient triggering methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

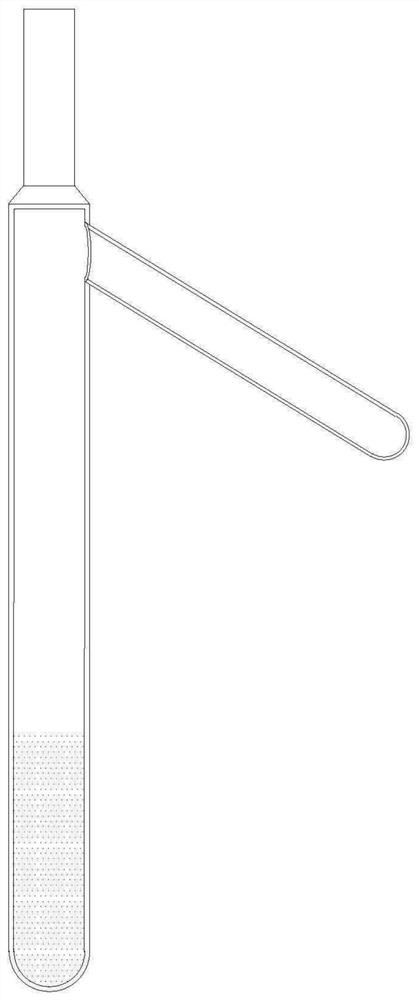

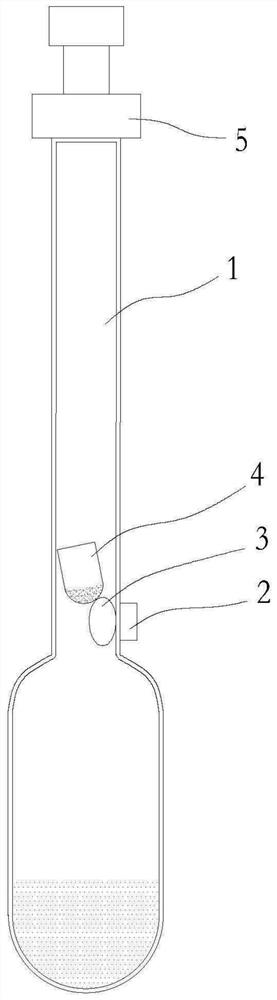

[0052] A device for acid hydrolysis using type I glass tubes, such as figure 2 As shown, it includes a type I glass tube 1, a magnet 2, a magnetic stirrer 3, a sample boat 4, a connecting joint 5 and a magnetic stirrer.

[0053] Type I glass tube 1 provides a space for acidolysis reaction, and the solution of acidolysis reaction is contained in type I glass tube 1. Magnet 2 is located on the outer wall side of Type I glass tube 1, and magnetic stirrer 3 is located on Type I glass tube 1. On one side of the inner wall, the magnet 2 and the magnetic stirrer 3 are attracted and fixed on the I-shaped glass tube 1;

[0054] The sample boat 4 is used to store samples. The sample boat 4 has an opening. The sample boat 4 is placed in the I-type glass tube 1 with the opening facing up (including vertically upward and inclined upward) and supported on the magnetic stirrer 3. Above, when the attraction force between the magnet 2 and the magnetic stirrer 3 is eliminated by external forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com