A kind of plasma module manufacturing method and plasma module

A plasma and production method technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as potential safety hazards and reduced treatment efficiency, and achieve the effect of eliminating "adhesion" area and increasing waste gas treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] like Image 6 As shown, this example provides a plasma module fabrication method, including the steps of:

[0049] S100: Extract the internal electrode and the outer electrode model, perform modal analysis; the modal frequency and amplitude of the internal electrode and the outer electrode are obtained, and the geometric dimensions of the inner electrode and the outer electrode and the material parameters are determined.

[0050] Specifically, see Step S102-S110.

[0051] S102: From the design drawing, an internal electrode and an outer electrode model are extracted, and the inner electrode and the outer electrode model are introduced into the ANSYS software, and the inner electrode and the outer electrode model are networked.

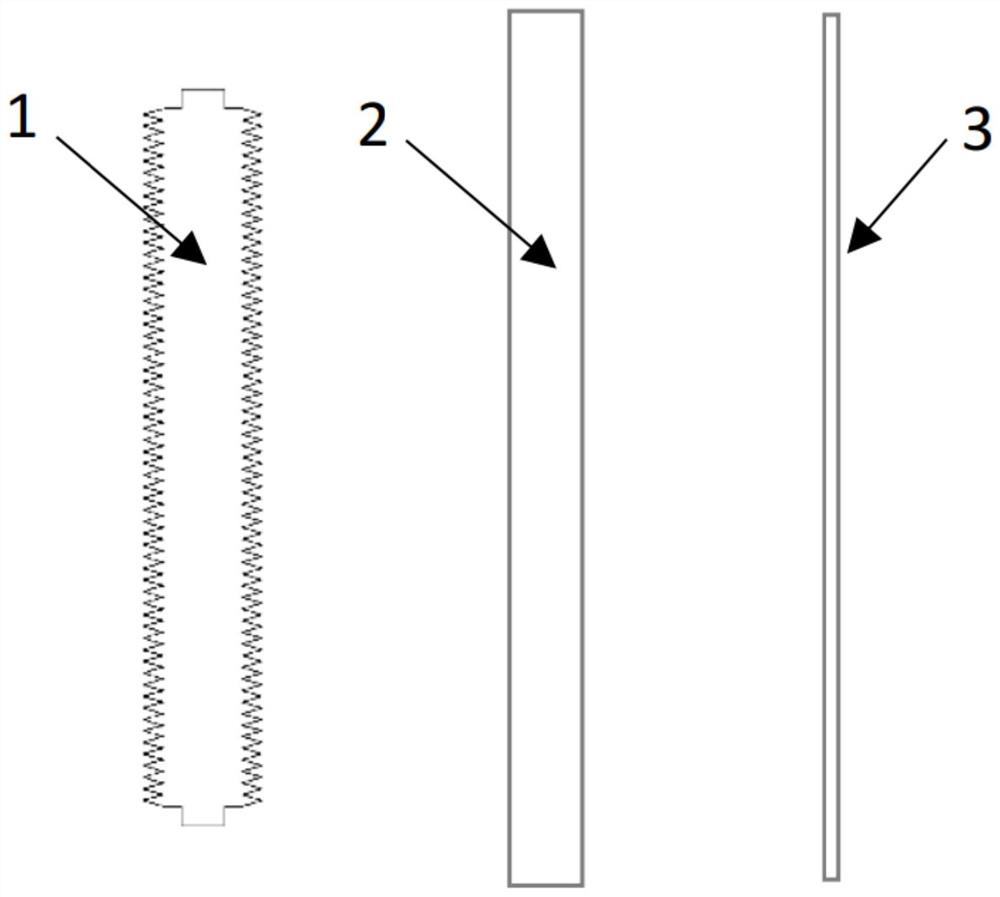

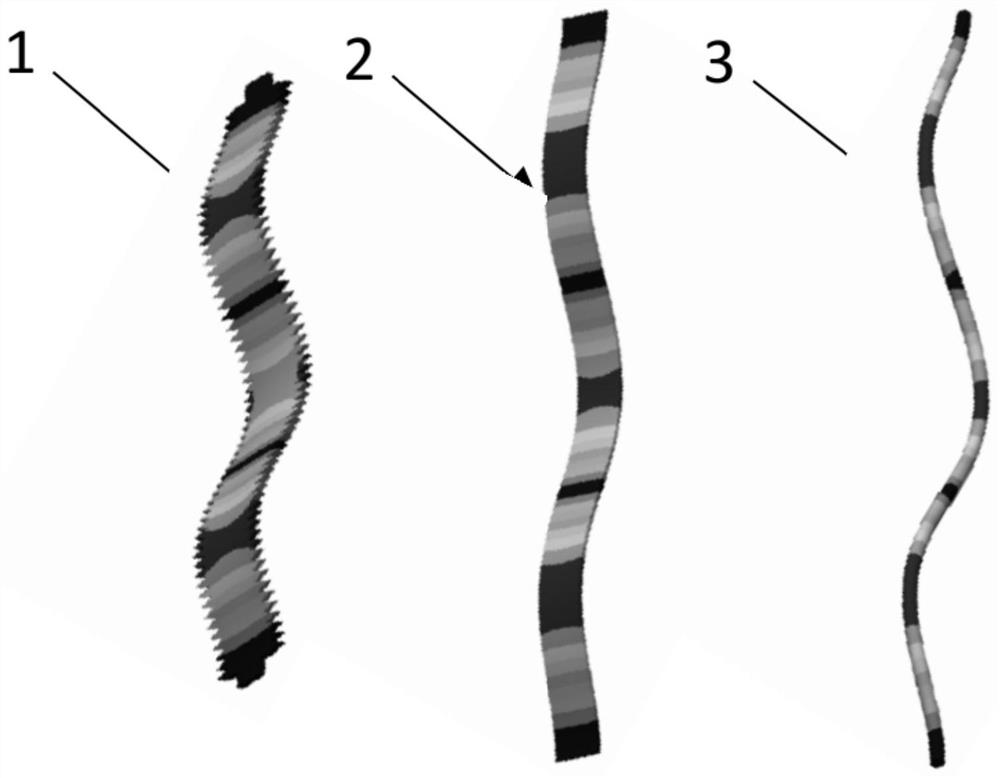

[0052] Specifically, the spatial size information of the internal electrode and the outer electrode is extracted from the design drawings, and the three-dimensional model is drawn. In this example, if figure 1 with 2 As shown, the extracted inner ele...

Embodiment 2

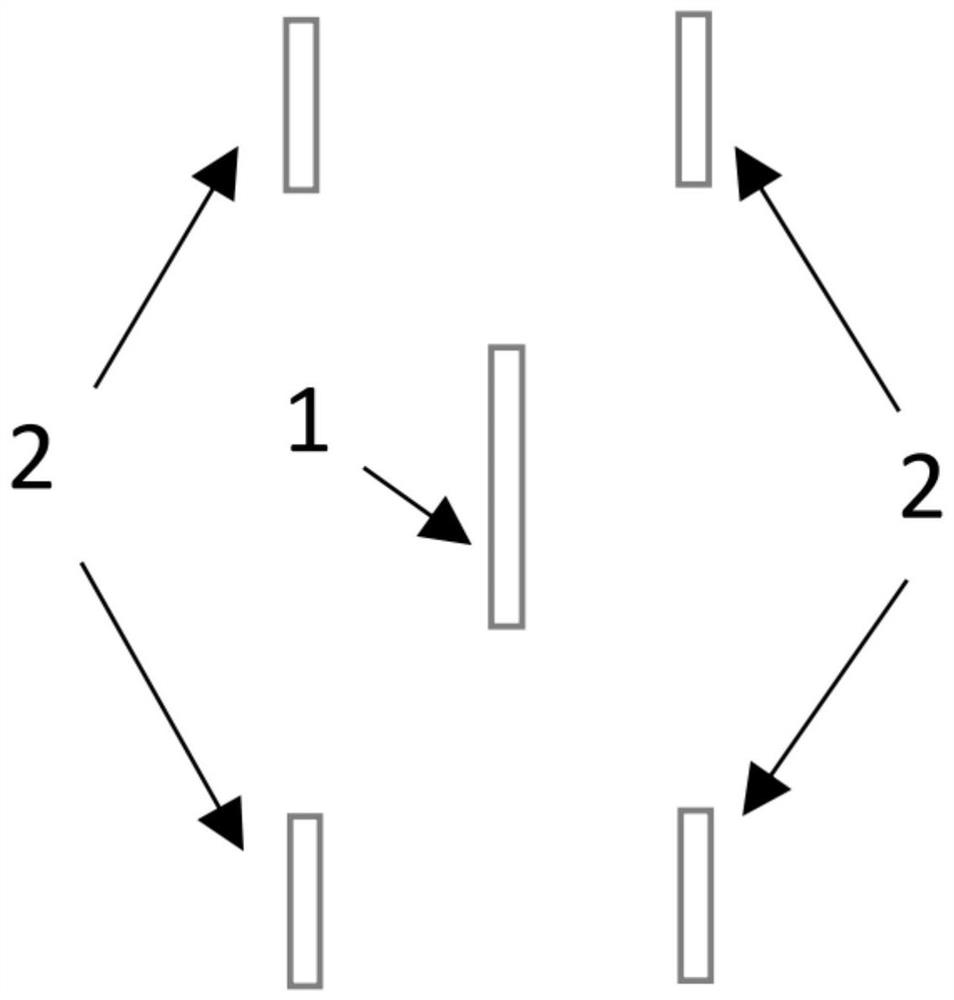

[0072] On the basis of the first embodiment, a plasma module is provided by the above-described plasma module fabrication method, wherein the plasma module includes an internal electrode sheet 1 and an outer electrode, an inner support frame 4. The outer support frame 5 and the insulator 6 are composed of one or both or both sides of the inner electrode sheet 1 having an equal distance arrangement, and is connected to the inner support frame 4; the outer electrode can be an external electrode sheet 2 Or one of the outer electrode rods 3; and the outer electrode is connected to the outer support frame, the inner support frame 4 and the outer support frame 5 connected by the insulator 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com