Solar silicon wafer anti-light-decay processing and conveying device and method

A technology of conveying device and silicon wafer, which is applied to conveyor objects, transportation and packaging, photovoltaic power generation, etc., can solve the problems of different light decay treatment effects of solar silicon wafers, reducing the quality of light decay treatment, and reducing the quality of solar silicon wafers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

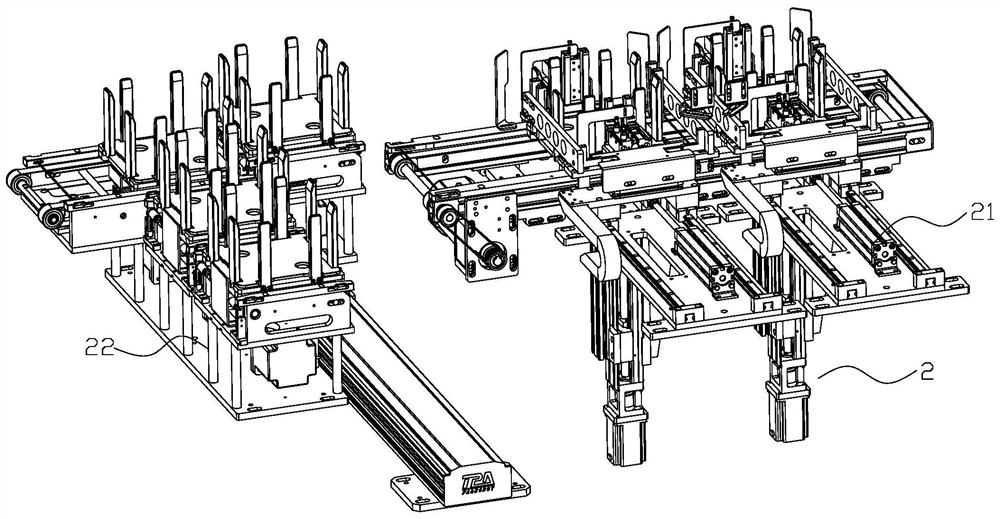

[0031]Such asfigure 1 The silicon wafer conveying device 2 shown includes a fixture feeding mechanism 21 and a fixture buffering mechanism 22; the fixture feeding mechanism 21 and the fixture buffering mechanism 22 are both fixed on the workbench, and the fixture feeding mechanism 21 The input end is connected with the output end of the silicon wafer feeding device 1, and the output end of the jig feeding mechanism 21 is connected with the input end of the jig buffer mechanism 22; the output end of the jig buffer mechanism 22 is connected with the light decay furnace inlet The jig feeding mechanism 21 is used to position and transport the solar silicon wafer; the jig buffer mechanism 22 is used to buffer the transferred surplus jig and output to the next station.

[0032]The product flow direction of solar silicon wafers is from the fixture feeding mechanism 21 to the fixture buffer mechanism 22.

[0033]Such asfigure 2 Shown is a schematic diagram of the product structure of a single sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com