Polyamic acid composition, polyimide copper-clad plate and circuit board

A technology of polyamic acid and polyimide film, which is applied in the direction of circuit substrate materials, printed circuits, printed circuits, etc., can solve the problems of low bonding force of copper foil, low bonding force of copper foil and polyimide film, etc. To achieve the effect of improving bonding strength, reducing mobility and reducing dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

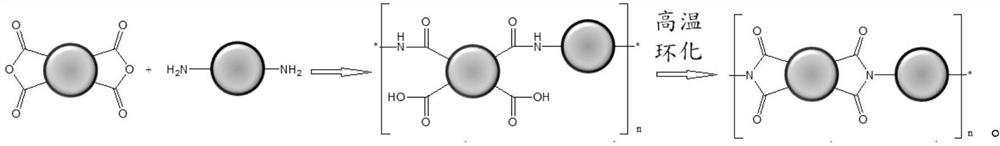

[0054] The preparation method of the polyamic acid composition can be: adding the diamine monomer containing the liquid crystal unit, the diamine monomer containing the soft structure and the diamine monomer containing the nitrogen heterocycle into a reaction bottle with a solvent; Stir to completely dissolve the diamine monomer containing the liquid crystal unit, the diamine monomer containing the soft structure and the diamine monomer containing the nitrogen heterocycle in the solvent; then, the dianhydride monomer containing the liquid crystal unit or the diamine monomer containing the soft structure At least one of the dianhydride monomers is added into the reaction flask, stirred and reacted for a period of time to obtain a polyamic acid composition. Wherein, the solvent is preferably a bipolar aprotic solvent. The bipolar aprotic solvent may be dimethylformamide (DMF), dimethylacetamide (DMAC), N-methylpyrrolidone (NMP), dimethylsulfoxide (DMSO) and the like. The added ...

Embodiment 1

[0068] Add NMP (203.37g), APAB (0.068mol, 15.52g), ODA (0.027mol, 5.41g), DTZ (0.005mol, 0.50g) into a 500mL reaction bottle, stir at high speed until dissolved, then add BPDA (0.1mol, 29.42g) under anhydrous nitrogen environment, stirred and reacted at lower than room temperature for 48 hours, that is, the polyamic acid composition was prepared.

Embodiment 2

[0070] Add NMP (205.77g), APAB (0.078mol, 17.80g), ODA (0.017mol, 3.40g), DTZ (0.005mol, 0.50g) into a 500mL reaction bottle, stir at high speed until dissolved, then add ODPA (0.02mol, 6.20g), BPDA (0.08mol, 23.54g) were stirred and reacted for 48 hours below room temperature under anhydrous nitrogen environment, and the polyamic acid composition was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com