Production method of nutritional gluten

A production method and technology for nutritious noodles, which are applied in the direction of vegetable protein processing, etc., to achieve the effects of improving the washout rate, reducing the content of gluten and starch, and enhancing elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

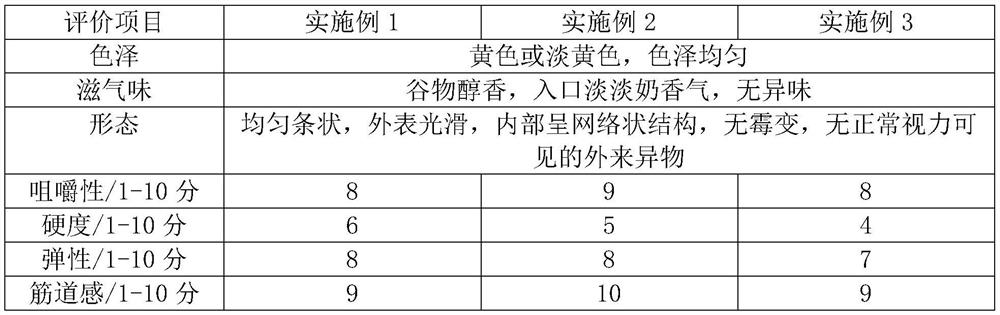

Examples

Embodiment 1

[0040] A production method of nutritional gluten, comprising the steps of:

[0041] (1) Kneading dough: mix the raw material wheat flour and water 1:1.5 in the kneading and kneading machine, the water contains 3% salt, pH=6.5, control the water temperature at 25°C while adding water and stirring, and switch to kneading mode after stirring evenly , knead the dough for 0.5 hours;

[0042] Preferably, the moisture content of the wheat flour is ≤14.0%, and the wet gluten content is ≥35%;

[0043] (2) Face washing: After kneading the dough, pump the dough into the cylindrical sieve for intermittent kneading and washing. The pH of the washing water is 6.5, and the ratio of water to material is 1.5:1. After kneading and washing for 8 minutes, drain the liquid and add the same amount of water to knead. wash, cycle three times;

[0044] (3) Dehydration: After washing the face, the gluten balls are pumped into a squeeze dryer for dehydration, and dehydrated gluten balls with a moistur...

Embodiment 2

[0058] A production method of nutritional gluten, comprising the steps of:

[0059] (1) Kneading dough: mix the raw material wheat flour and water 1:1.8 in the kneading and kneading machine, the water contains 3% salt, pH=6.8, control the water temperature at 26°C while adding water while stirring, and switch to the kneading mode after stirring evenly , knead the dough for 0.5 hours;

[0060] Preferably, the moisture content of the wheat flour is ≤14.0%, and the wet gluten content is ≥35%;

[0061] (2) Face washing: After kneading the dough, pump the dough into the cylindrical sieve for intermittent kneading and washing. The pH of the washing water is 6.8, and the ratio of water to material is 1.5:1. After kneading and washing for 8 minutes, drain the liquid and add the same amount of water to knead. wash, cycle three times;

[0062] (3) Dehydration: After washing the face, the gluten balls are pumped into a squeeze dryer for dehydration, and dehydrated gluten balls with a m...

Embodiment 3

[0076] A production method of nutritional gluten, comprising the steps of:

[0077] (1) Kneading dough: mix the raw material wheat flour and water 1:1.8 in the kneading kneading machine, the water contains 3% salt, pH=7.0, control the water temperature at 28°C and add water while stirring, and switch to kneading mode after stirring evenly , knead the dough for 0.5 hours;

[0078] Preferably, the moisture content of the wheat flour is ≤14.0%, and the wet gluten content is ≥35%;

[0079] (2) Face washing: After kneading the dough, pump the dough into a cylindrical sieve for intermittent kneading and washing. The pH of the washing water is 7.0, and the ratio of water to material is 1.8:1. After kneading and washing for 8 minutes, drain the liquid and add the same amount of water to knead. wash, cycle three times;

[0080] (3) Dehydration: After washing the face, the gluten balls are pumped into a squeeze dryer for dehydration, and dehydrated gluten balls with a moisture content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com