Chopstick slitting and forming machine

A technology of forming machine and chopsticks, applied in the direction of forming/shaping machine, special forming/shaping machine, mechanical equipment, etc., can solve the problems of heavy weight, cumbersome equipment feeding operation, unfavorable processing efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

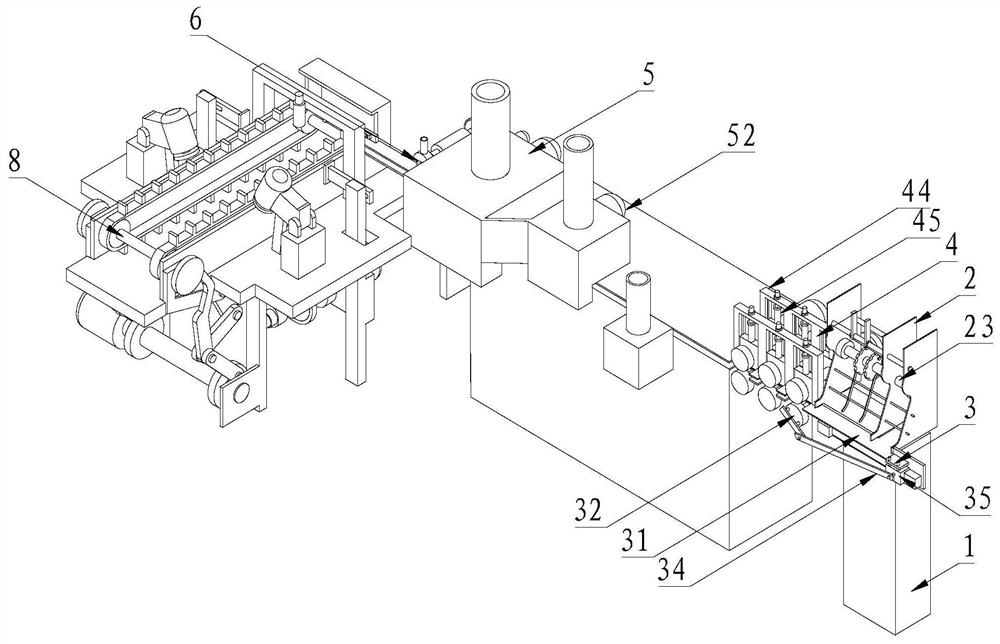

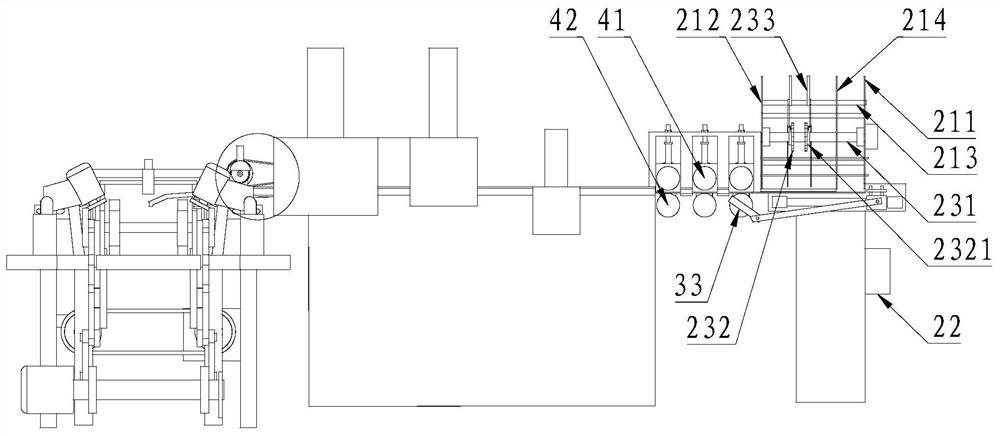

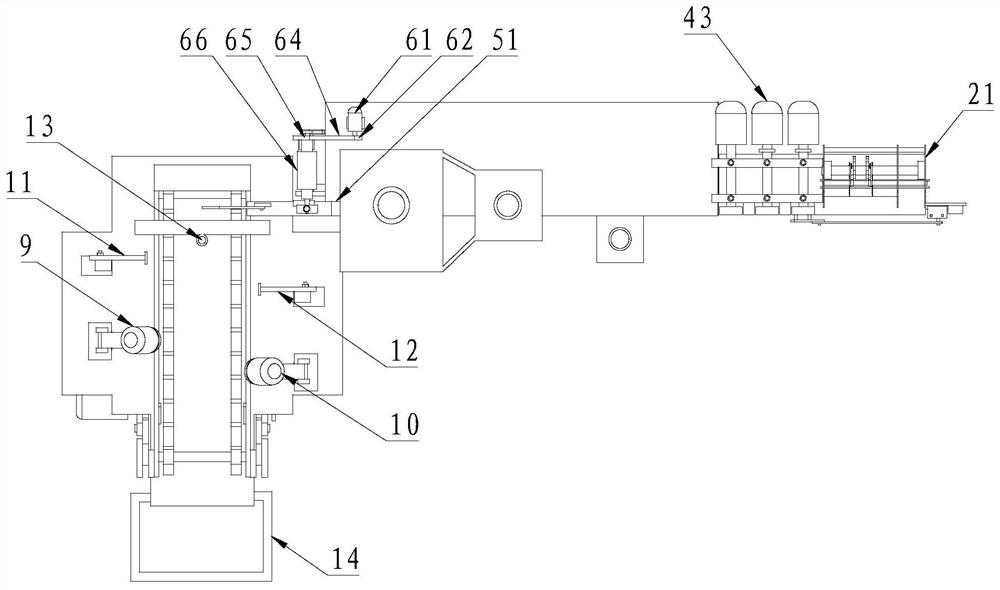

[0067] Please refer to Figure 1 to Figure 10 Shown, embodiment one of the present invention is:

[0068] A chopsticks cutting and forming machine, comprising a machine tool 1 and a blanking mechanism 2, an intermittent pushing mechanism 3, a continuous feeding mechanism 4, an edge grinding mechanism 5 and an intermittent cutting mechanism 6 respectively installed on the machine tool 1;

[0069]The blanking mechanism 2 includes a raw material storage box 21, a first motor 22 and a material shifting assembly 23, the raw material storage box 21 is arranged on the machine tool 1, the inside of the raw material storage box 21 is hollow, and the raw material storage box 21 is hollow. The top and the bottom of the box 21 are respectively provided with a material inlet and a material outlet through the inner cavity of the raw material storage box 21, the first motor 22 is arranged on the machine tool 1, and the first motor 22 passes through The first transmission assembly is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com