A kind of yeast production preparation process

A preparation process, yeast technology, applied in the direction of biochemical equipment and methods, fungi, biochemical instruments, etc., can solve the problems of unfavorable disassembly and cleaning, low filtration degree, poor filtration effect, etc., to improve the filtration and removal effect, avoid Pollution, the effect of increasing the amount of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

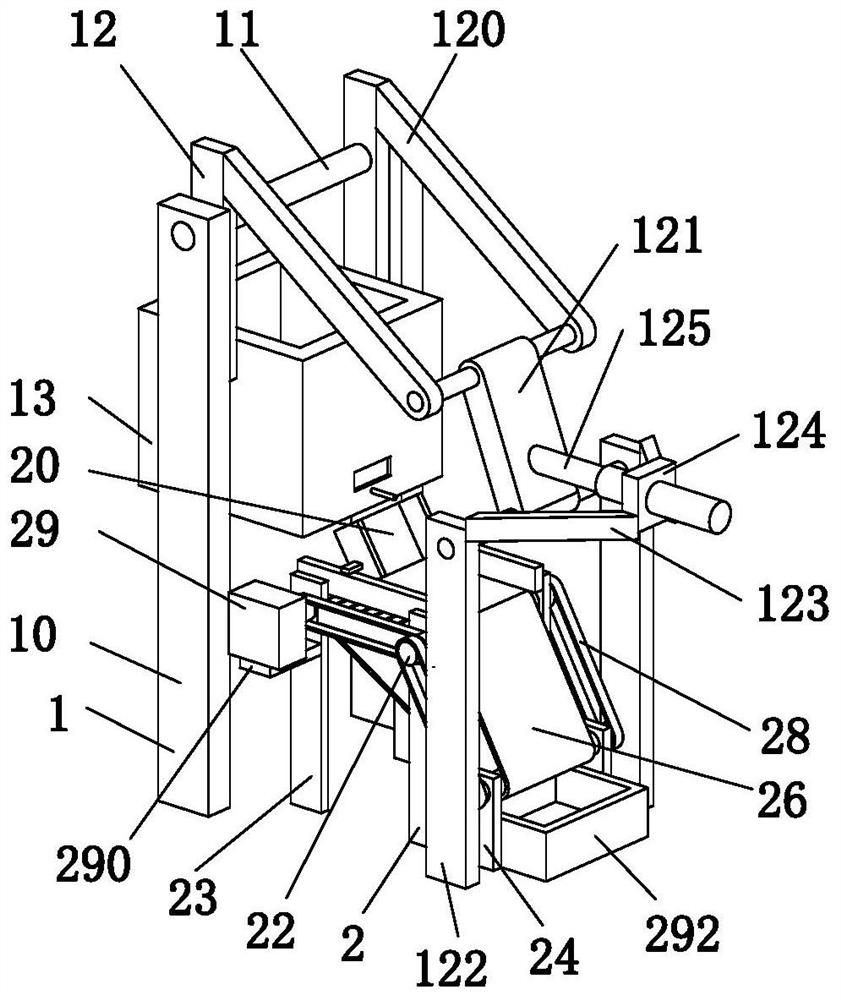

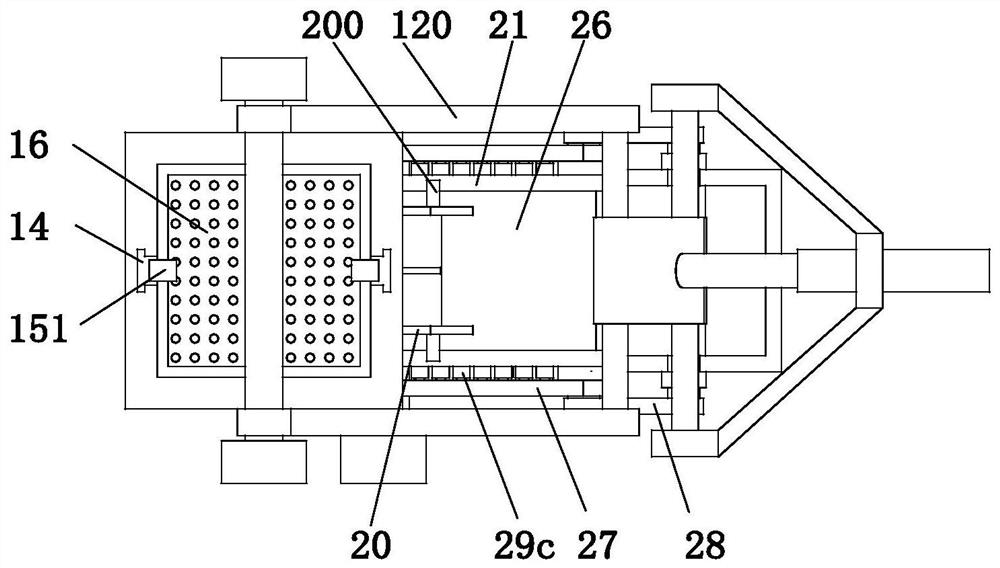

[0038] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

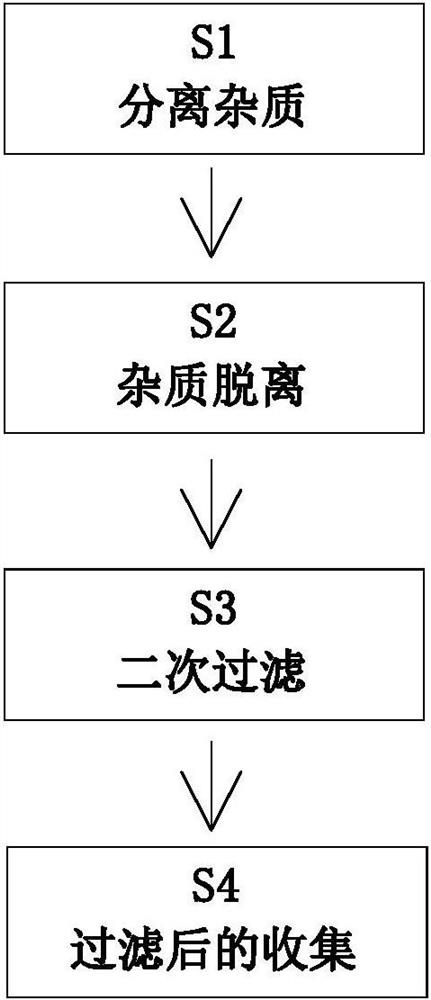

[0039] Such as Figure 1 to Figure 11 As shown, a yeast production and preparation process uses a yeast production and preparation device, the yeast production and preparation device includes a supernatant mechanism 1 and a lower cleaning mechanism 2, and the yeast production and preparation device is used for yeast production Concrete preparation process during preparation is as follows:

[0040] S1. Separation of impurities: pour the yeast emulsion into the processing basket 13 manually, let it stand for a certain period of time, light impurities float on the surface, and then drive the sieve plate 16 to press the yeast emulsion downward through the electric slider 14 During the process, the light impurities float up to the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com