Plant fiber filter element forming device of engine oil filter and using method thereof

A technology of oil filter and plant fiber, which is applied in the direction of textiles and papermaking, can solve the problems of poor oil passing capacity, cumbersome production process, and high physical exertion, and achieve the effects of improving efficiency, increasing corporate income, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

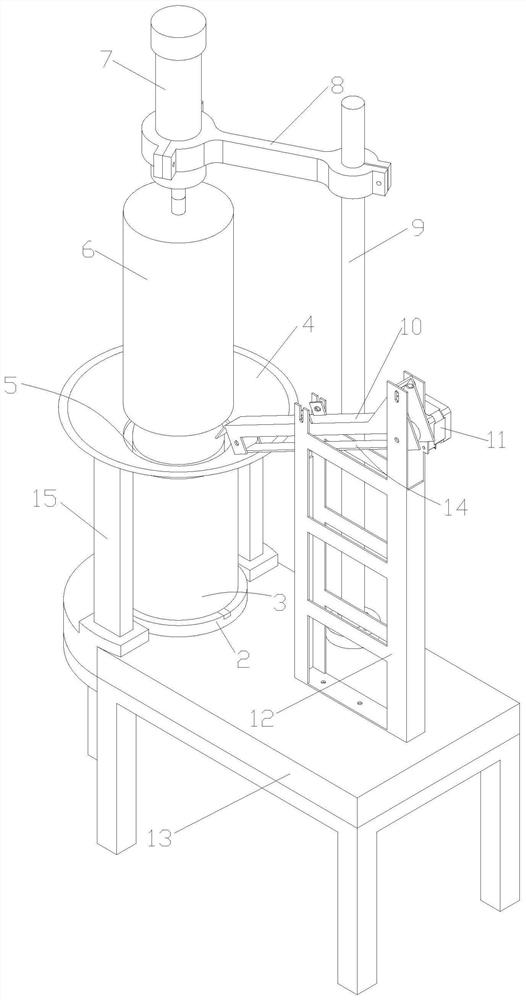

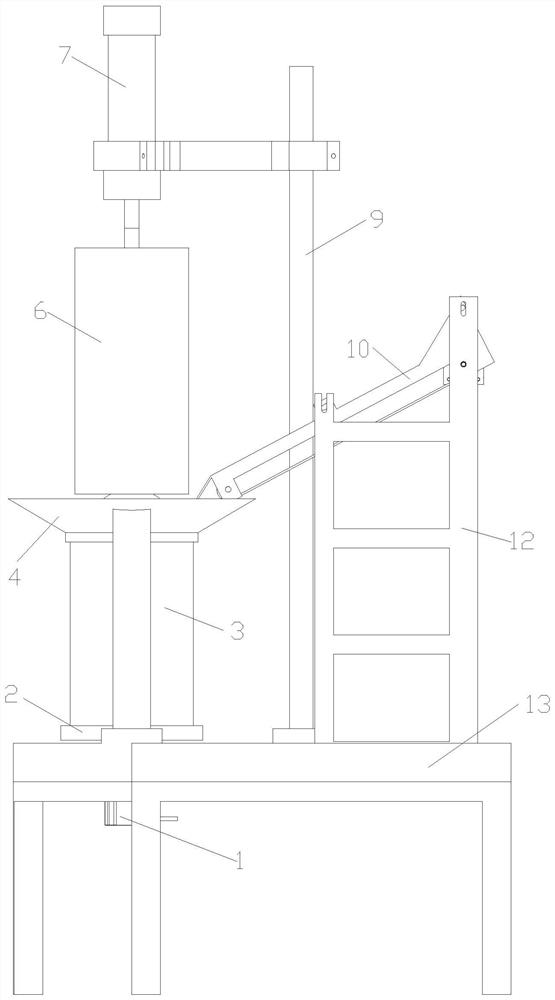

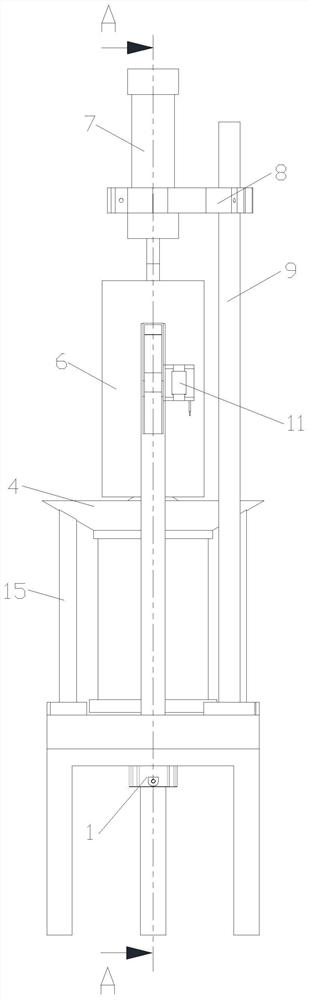

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] see Figure 1 to Figure 5 , the present invention provides a plant fiber filter element forming device for an oil filter, including a workbench 13, a rotating base 2 is installed on the left part of the workbench 13, an outer cylinder 3 is installed on the rotating base 2, and the An inner cylinder 5 is mounted on the rotating base 2 inside the outer cylinder 3, a support base 12 is installed on the right part of the workbench 13, and a conveyor belt 14 is installed on the support base 12, and the conveyor belt 14 is close to the outer cylinder One end of 3 is docked with the outer cylinder 3, and a support rod 9 is installed on the workbench 13 placed on the conveyor belt, and a connecting block 8 is fixed on the support rod 9, and a connecting block 8 is installed on the connecting block 8. Telescopic cylinder 7, the lower end of the push rod of the telescopi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com