Shape-optimized assembly type shear damper with staged yield energy dissipation mechanism

A staged, prefabricated technology, applied in building types, protective buildings/shelters, building components, etc., can solve the problems of single energy consumption form, insufficient ductility, insufficient energy consumption capacity, etc., and achieve stable mechanical properties, Good ductility and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

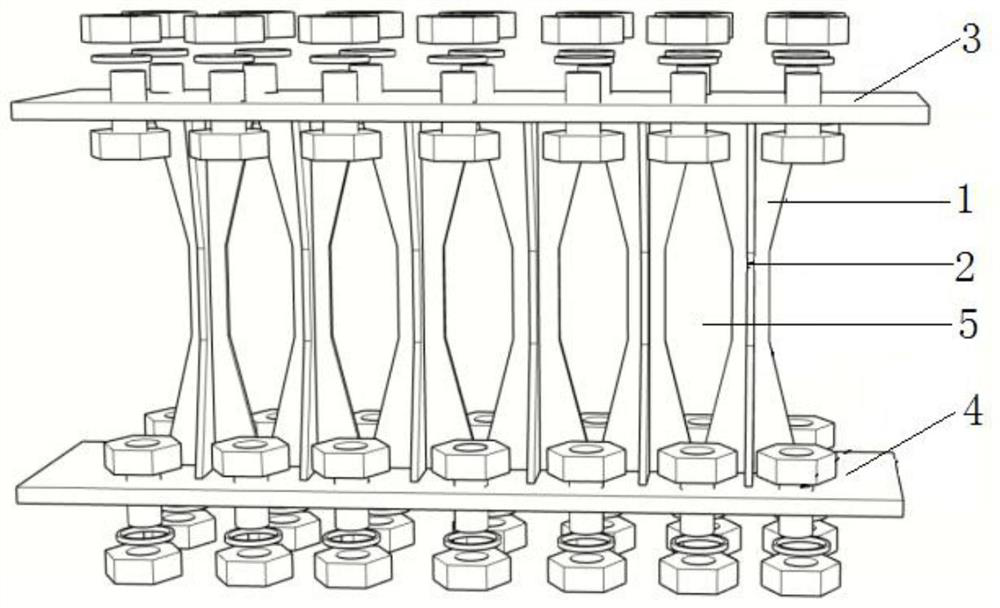

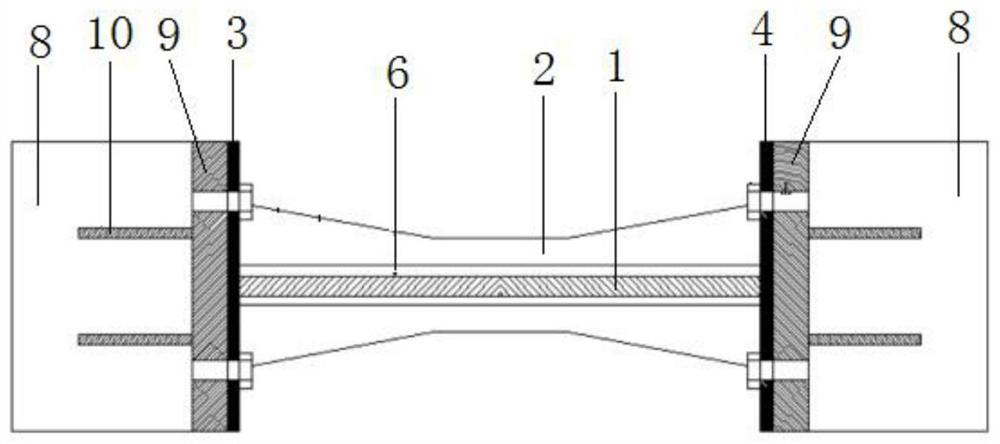

[0026]See attachedFigure 1-6The embodiment of the present invention discloses an assembled shear-type damper with an optimized shape-optimized staged yield energy dissipation mechanism, including: in-plane deformation energy dissipation sheet 1, out-of-plane deformation energy dissipation sheet 2, first connecting plate 3, and second Two connecting plates 4, the first connecting plate 3 and the second connecting plate 4 are arranged in parallel, the in-plane deformation energy dissipation sheet 1 and the out-of-plane deformation energy dissipation sheet 2 are fixed to the first connecting plate 3 and the second connecting plate by welding Between 4.

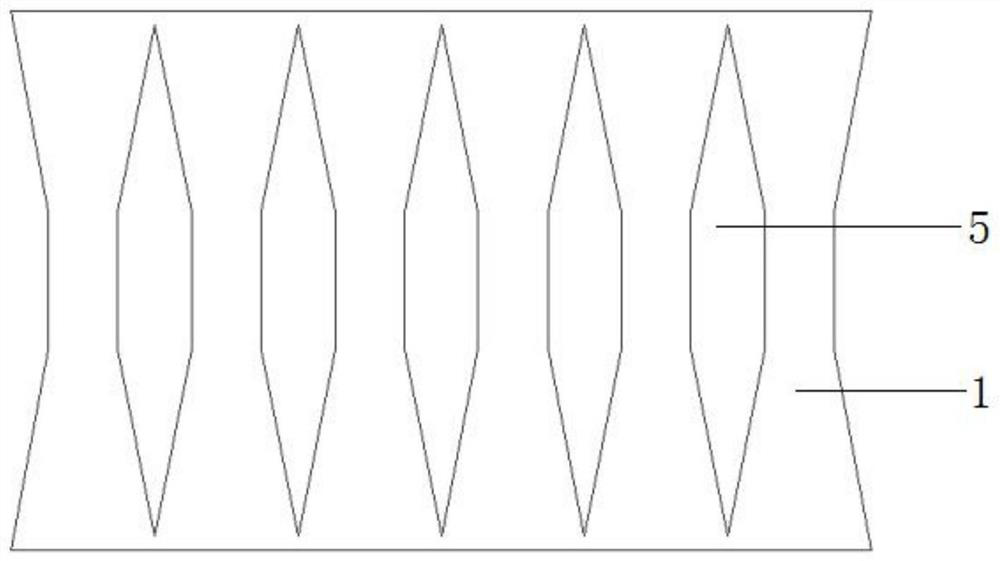

[0027]Among them, the in-plane deformation energy dissipation sheet 1 is provided with a plurality of through holes 5 in an array in the length direction. The through holes 5 are gradually condensed from the middle to the two ends, and the two ends respectively face the first connecting plate 3 and the second connecting plate. On the conn...

Embodiment 2

[0032]See attachedFigure 7 Assemble the assembled shear-type damper of the staged yield energy dissipation mechanism with the optimized shape to the interlayer of the frame structure, and use the displacement between the layers during the earthquake to drive the damper to work and consume energy. Specifically, the first The connecting plate 3 is fixedly connected with the embedded connecting steel plate 9 under the upper frame beam 12 by bolts, the second connecting plate 4 is connected with the embedded connecting steel plate 9 fixed on the concrete connecting butt 13 by bolts, and the concrete connecting butt 13 is located on the lower layer Above the frame girder 14, the concrete connecting buttress 13 and the lower frame girder 14 are integrally poured. The concrete connecting buttress 13 has sufficient bearing capacity and initial rigidity to avoid exiting work before the damper yields. The method of fixing the embedded connecting steel plate 9 under the upper frame beam 12 and...

Embodiment 3

[0034]See attachedFigure 8 , The first connecting plate 3 in the assembled shear-type damper of the staged yield energy dissipation mechanism optimized by the shape is connected with the embedded connecting steel plate 9 under the upper frame beam 12 by bolts, and the upper frame beam 12 and Two connecting supports 15 are arranged between the lower frame beams 14. The two connecting supports 15 are arranged in a V shape. The lower end of the connecting support 15 is fixed at the connection between the lower frame beam 14 and the vertical frame, and the upper ends of the two connecting supports 15 The second connecting plate 4 in the assembled shear-type damper with a staged yield energy dissipation mechanism optimized for the shape of the intersection and fixed connection, and the intersection and the shape are fixedly connected by bolts, in the upper frame beam 12 and the lower frame beam 14 The infill wall 16 is arranged in the gap, and the connecting support 15 adopts a steel str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com