A remote on-line monitoring and optimization method for scr efficiency of a diesel engine

An optimization method, diesel engine technology, applied in mechanical equipment, engine components, combustion engines, etc., can solve problems such as increased customer complaints, decreased SCR efficiency, time-consuming and labor-intensive problems, so as to improve data quality and robustness, and resolve customer complaints , The effect of liberating engineer resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

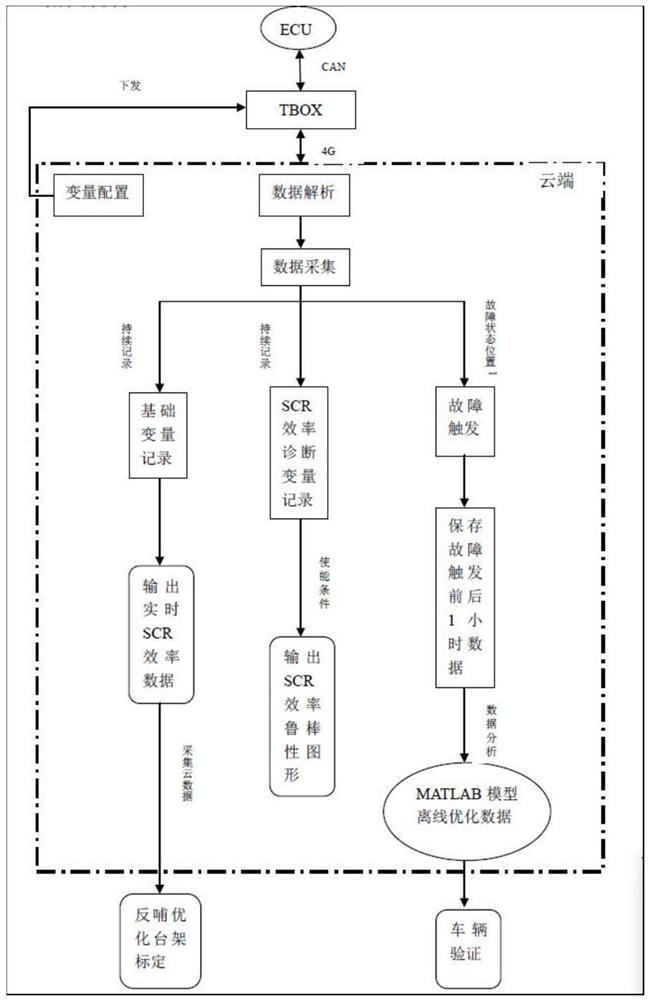

[0039] see figure 1 , the diesel engine SCR efficiency remote online monitoring and optimization method of the present invention includes the acquisition of SCR efficiency measurement signals and the monitoring and optimization process of signals, wherein:

[0040] Signal acquisition part: use TBOX remote terminal equipment to connect the ECU and the cloud, set the variable configuration in the cloud and send it to TBOX for measurement signal acquisition; among them, the communication between TBOX and ECU is based on the XCP protocol of the CAN line, and the communication between TBOX and the cloud Signal transmission through wireless network strategies such as 4G / 5G;

[0041] Monitoring optimization part: After the data is uploaded to the cloud, the data is monitored, analyzed and optimized:

[0042] 1) Continuously record and save basic variables such as rotational speed, oil volume, torque, vehicle speed, ambient temperature, water temperature, intake air volume, and real-...

Embodiment 2

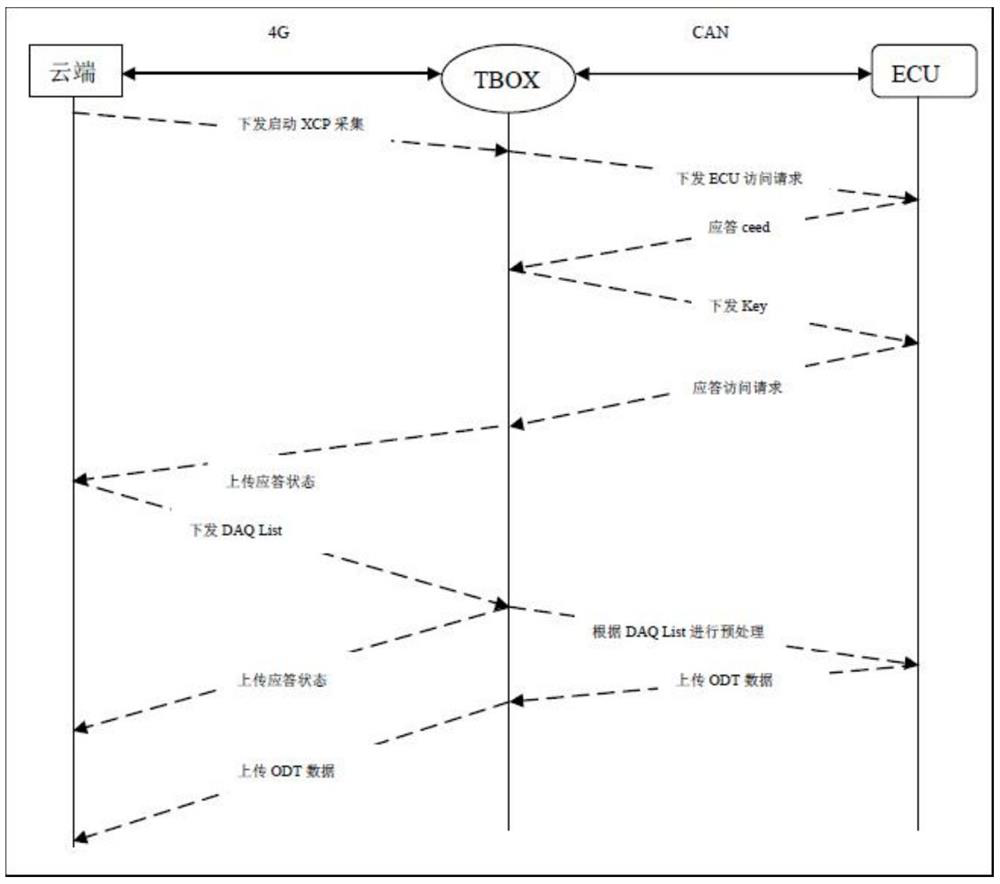

[0046] see figure 1 , figure 2 . The remote on-line monitoring and optimization method of diesel engine SCR efficiency of the present embodiment, and the difference of embodiment 1 are: further, such as figure 2 As shown, the acquisition process of the measurement signal includes:

[0047] 1) The cloud sends the collection command and sends the DAQ List configuration

[0048] 2) TBox accesses ECU to request security authentication

[0049] 3) XCP DAQ List preprocessing, DAQ List mainly includes the following (generated through A2L file conversion)

[0050] (1) List unique identification number

[0051] (2) ODT unique identification number

[0052] (3) elements

[0053] (4) Element length

[0054] (5) Page address

[0055] (6) address

[0056] 4) Collect ODT data and upload it to the cloud.

[0057] figure 2 It is the interactive communication interface between the cloud, TBOX, and ECU. The TBOX device communicates with the ECU through the CAN line, and the cloud a...

Embodiment 3

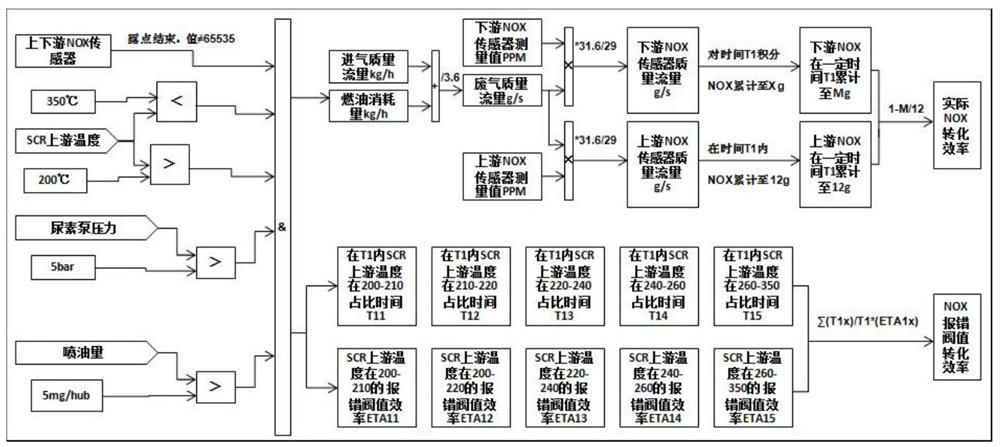

[0059] The remote online monitoring and optimization method of diesel engine SCR efficiency in this embodiment differs from Embodiment 1 or Embodiment 2 in that: further, the monitoring and optimization part: when the fault state position 1 fault is triggered, the 1 before and after the fault trigger is automatically saved. Hours of data, input this part of the data to the MATLAB model for offline optimization, verify the optimized data on the real vehicle, and solve the fault. For the SCR efficiency calculation model, see image 3 shown.

[0060] image 3 is a schematic diagram of the SCR efficiency model of MATLAB. When the dew point of the upstream and downstream NOx sensors is released, the upstream temperature of the SCR is between 200°C and 350°C, the urea pump pressure is 5bar, and the fuel injection volume is greater than 5mg / hub, the PPM measured values of the upstream and downstream NOx sensors are respectively multiplied by the exhaust gas flow rate and integrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com