Semi-circle type low-temperature novel expansion joint

An expansion joint and semi-arc technology, which is applied in the field of semi-arc low-temperature new expansion joints, can solve the problems of excessive extension of the outer material, large bending angle, corrosion and perforation, etc., and achieve light weight, small workload, and easy handling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further described and understood by non-limiting examples below.

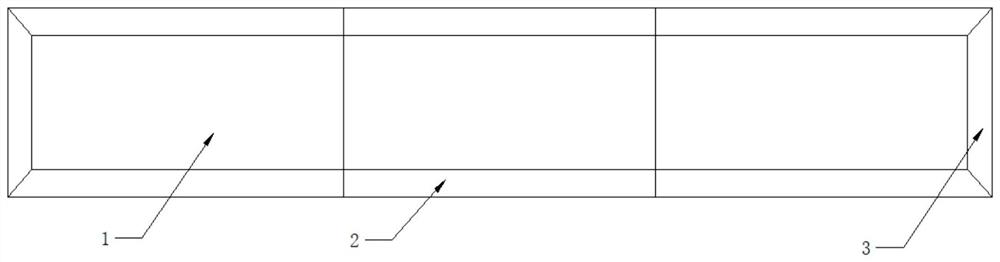

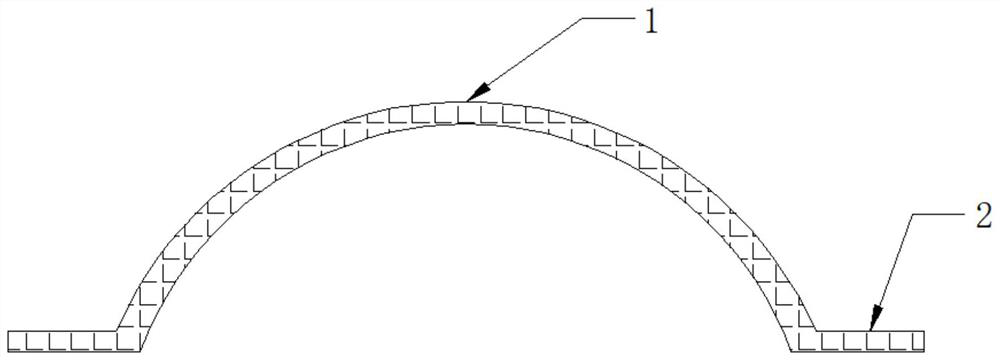

[0018] Such as Figure 1-2 As shown, the present invention is a semi-arc type low-temperature new expansion joint, which is installed at the inlet and outlet of the induced draft fan and the booster fan, as well as the original flue and the clean flue of the desulfurization absorption tower. node, the material of the wave node is duplex stainless steel, such as 2205 stainless steel; The arc length of 1 corresponds to a central angle of 140°;

[0019] During on-site installation, the original traditional expansion joints are cut, and then the first connection part 2 of each wave node is welded to the remaining pipe wall of the on-site flue. The second connection part 3 is welded below the wave node to form an integral structure with the wave node body 1 and the first connection part 2 respectively.

[0020] In the present invention, due to the simple structure and light weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com