Stainless steel intercooling air inlet pipe manufacturing forming method

A molding method and air intake pipe technology, which is applied in the field of air intake pipes, can solve the problems of affecting the safety of use, easy rust and cracking of intercooled air intake pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

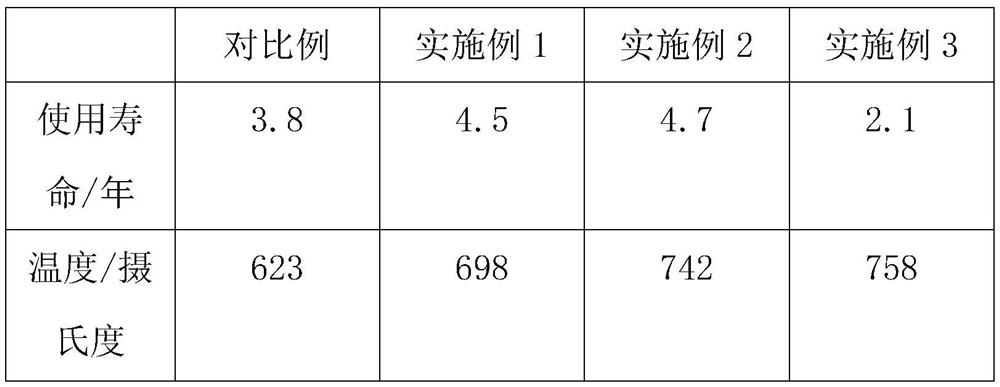

Embodiment 1

[0030] Step 1: General mechanical equipment preparation stage: After testing the function of the equipment, turn it on and enter the standby state, conduct basic testing on the materials involved in the work, remove unqualified materials, and re-examine the materials after removal;

[0031] Step 2: Heat forming and testing of the intercooled intake pipe; sieve out iron, carbon, silicon, nickel, chromium, tantalum and niobium, then fill the iron and carbon in the related materials into the sealed smelting furnace, and then close the furnace door , wait for its temperature to rise to 1300 degrees Celsius, then keep the temperature in the sealed smelting furnace for 5, then take out the molten iron after heat preservation, pour the molten metal melt into the smelting mold, and when the mold itself cools to room temperature, take out the product in the mold spare;

[0032] Step 3: Test operation of the intercooler intake pipe: place the taken out intercooler intake pipe into the a...

Embodiment 2

[0038]Step 1: General mechanical equipment preparation stage: After testing the function of the equipment, turn it on and enter the standby state, conduct basic testing on the materials involved in the work, remove unqualified materials, and re-examine the materials after removal;

[0039] Step 2: Heat forming and testing of the intercooled intake pipe; sieve out iron, carbon, silicon, nickel, chromium, tantalum and niobium, then fill the iron and carbon in the related materials into the sealed smelting furnace, and then close the furnace door , when the temperature rises to 1350 degrees Celsius, then keep the temperature in the sealed smelting furnace for 7.5 minutes, then take out the molten iron after heat preservation, pour the molten metal melt into the smelting mold, and when the mold itself cools to room temperature, put the product in the mold Take out spare;

[0040] Step 3: Test operation of the intercooler intake pipe: place the taken out intercooler intake pipe int...

Embodiment 3

[0046] Step 1: General mechanical equipment preparation stage: After testing the function of the equipment, turn it on and enter the standby state, conduct basic testing on the materials involved in the work, remove unqualified materials, and re-examine the materials after removal;

[0047] Step 2: Heat forming and testing of the intercooled intake pipe; sieve out iron, carbon, silicon, nickel, chromium, tantalum and niobium, then fill the iron and carbon in the related materials into the sealed smelting furnace, and then close the furnace door , when the temperature rises to 1400 degrees Celsius, then keep the temperature in the sealed smelting furnace for 10 minutes, then take out the molten iron after heat preservation, pour the molten metal melt into the smelting mold, and when the mold itself cools to room temperature, put the product in the mold Take out spare;

[0048] Step 3: Test operation of the intercooler intake pipe: place the taken out intercooler intake pipe int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com