Novel efficient anti-sticking kettle agent for PVC suspension polymerization production and preparation method of novel efficient anti-sticking kettle agent

A technology of anti-sticking agent and suspension polymerization, applied in the direction of coating, etc., can solve the problems of difficult to meet the production requirements of PVC polymerization, poor anti-sticking effect, poor wall coating effect, etc., and achieve synergistic effect, good wall coating effect, Effect of improving anti-stick performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

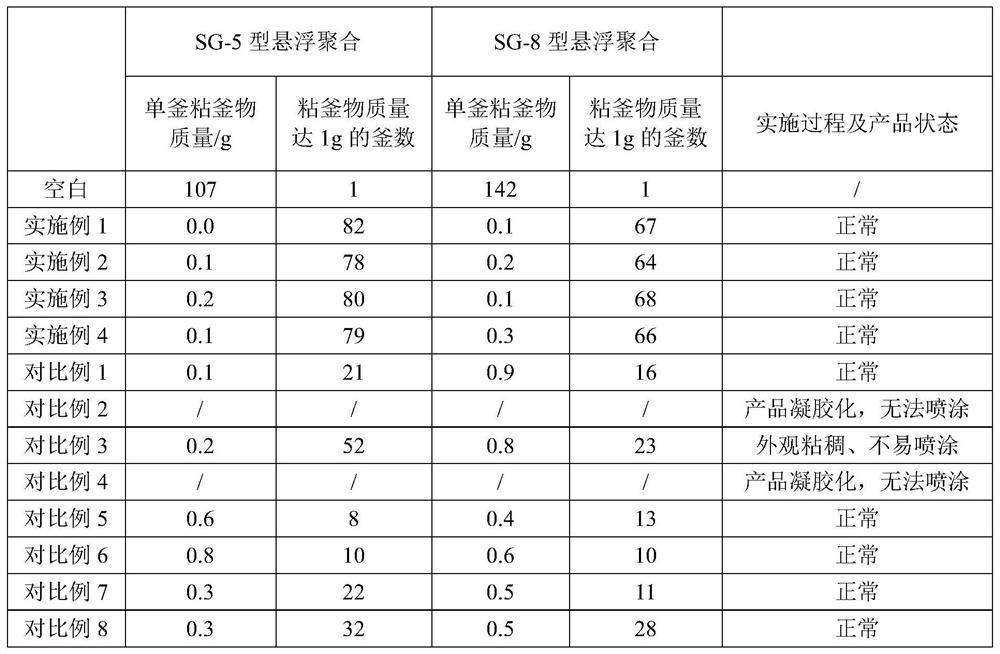

Examples

preparation example Construction

[0033] The present invention provides a preparation method of the above-mentioned novel high-efficiency anti-sticking agent. The method has the characteristics of simple production process, easy-to-obtain raw materials, low product use cost, and convenient industrialization and application. It specifically includes the following steps:

[0034] (1) Add water to the reaction kettle first, start stirring, the stirring speed is 2500-3000r / min, and the stirring time is 15-30min. The temperature was raised to 65-70°C, and nitrogen gas was continuously purged.

[0035](2) Add the 1, 4, 5, 8-tetrahydroxynaphthalene and sodium hydroxide in the recipe amount into the kettle, and stir until they are completely dissolved.

[0036] (3) Mix and dissolve o-hydroxybenzaldehyde, sodium formaldehyde sulfoxylate and part of deionized water, add it dropwise to the reaction kettle, and keep warm at 70-75°C for 2.5-3 hours.

[0037] (4) The temperature of the reaction kettle is raised to 90°C, an...

Embodiment 1

[0044] The composition and ratio of the anti-sticking pot agent are: 5% o-hydroxybenzaldehyde, 5% 1, 4, 5, 8-tetrahydroxynaphthalene, 2% 1-naphthol-4-carboxylic acid, sodium formaldehyde sulfoxylate 2%, polyvinyl alcohol 2%, sodium hydroxide 2%, sodium sulfite 1%, methanol 10%, and the balance is deionized water.

[0045] The preparation method of the anti-sticking pot agent: first add 20% water to the reaction kettle, start stirring, the stirring speed is 2500r / min, and the stirring time is 25min; the temperature is raised to 70°C, and nitrogen is continuously purged. Then add 5% tetrahydroxynaphthalene and 1% sodium hydroxide into the kettle, and stir until completely dissolved. Continue to mix 5% o-hydroxybenzaldehyde, 2% sodium formaldehyde sulfoxylate and 10% deionized water to prepare and dissolve, then add dropwise to the reaction kettle, and keep warm at 70° C. for 3 hours. The temperature of the reactor was raised to 90°C, and 2% of 1-naphthol-4-carboxylic acid, 1% o...

Embodiment 2

[0047] The composition and ratio of the anti-sticking pot agent are: o-hydroxybenzaldehyde 1%, 1, 4, 5, 8-tetrahydroxynaphthalene 6%, 1-naphthol-4-carboxylic acid 3%, formaldehyde sodium sulfoxylate 1%, polyvinyl alcohol 3%, potassium hydroxide 2%, sodium bisulfite 1%, methanol 15%, and the balance is deionized water.

[0048] The preparation method of the anti-sticking pot agent: first add 20% water to the reaction kettle, start stirring, the stirring speed is 2600r / min, and the stirring time is 15min; the temperature is raised to 70°C, and nitrogen is continuously purged. Then add 6% of 1,4,5,8-tetrahydroxynaphthalene and 1% of potassium hydroxide into the kettle and stir until completely dissolved. Continue to mix 1% o-hydroxybenzaldehyde, 1% sodium formaldehyde sulfoxylate and 10% deionized water to prepare and dissolve, then add dropwise to the reaction kettle, and keep warm at 70°C for 2.5h. The temperature of the reactor was raised to 90°C, 3% of 1-naphthol-4-carboxyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com