Production method of patterned toning film

A production method and a technology for coloring film, which are applied in the field of preparation of intelligent PDLC liquid crystal coloring film, can solve the problems of influence of dot matrix accuracy, poor image accuracy and high cost, and achieve the effects of good display effect, easy manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

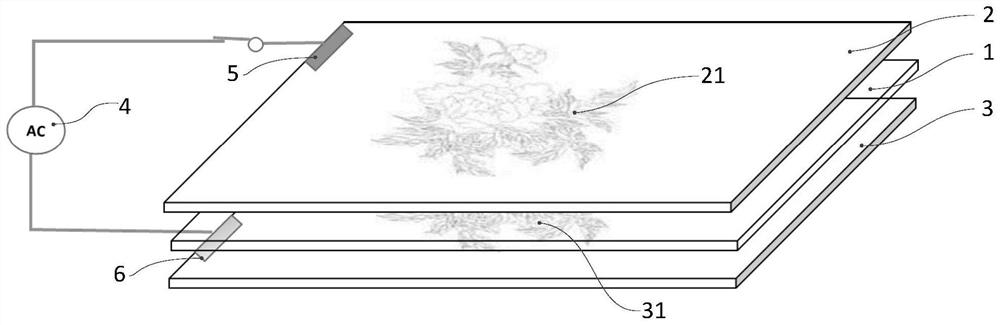

[0049] The production method of the patterned toning film of the present invention is used for preparing the patterned toning film; the patterned toning film comprises a PDLC liquid crystal layer 1, a positive pattern conductive layer 2, and a negative pattern conductive layer 3; The positive pole of the power supply 4 is connected to the positive pole 5 of the positive pattern conductive layer 2 through a wire, and the negative pole of the power supply 4 is connected to the negative pole 6 of the negative pattern conductive layer 3 through a wire; the power supply 4 is connected to , so that the patterned toner film exhibits a preset pattern.

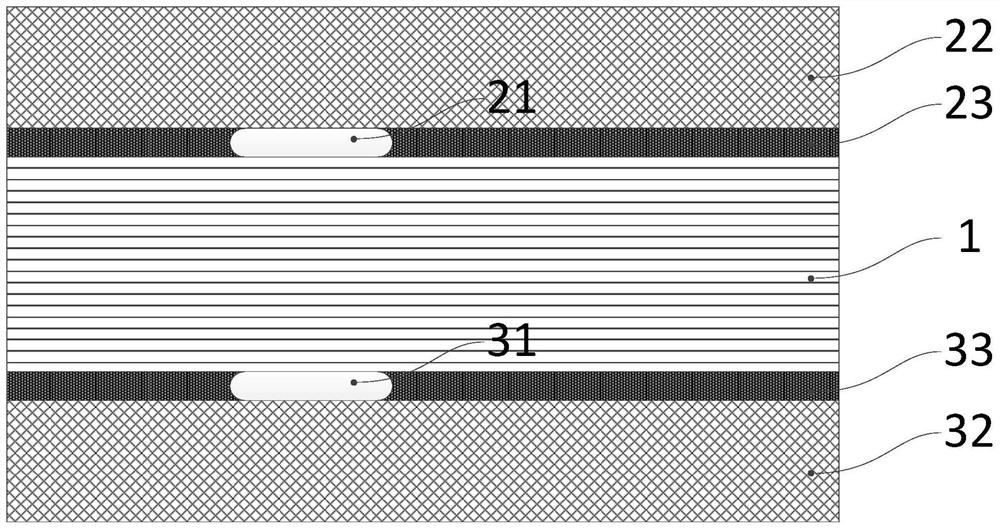

[0050] The specific structure of the patterned toning film is as follows: figure 2 As shown, the positive electrode pattern conductive layer 2 is provided with a positive electrode pattern 21, and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com