Power semiconductor device and preparation method thereof

A technology of power semiconductors and devices, which is applied in the field of power semiconductor devices and their preparation, and can solve problems affecting the avalanche tolerance of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

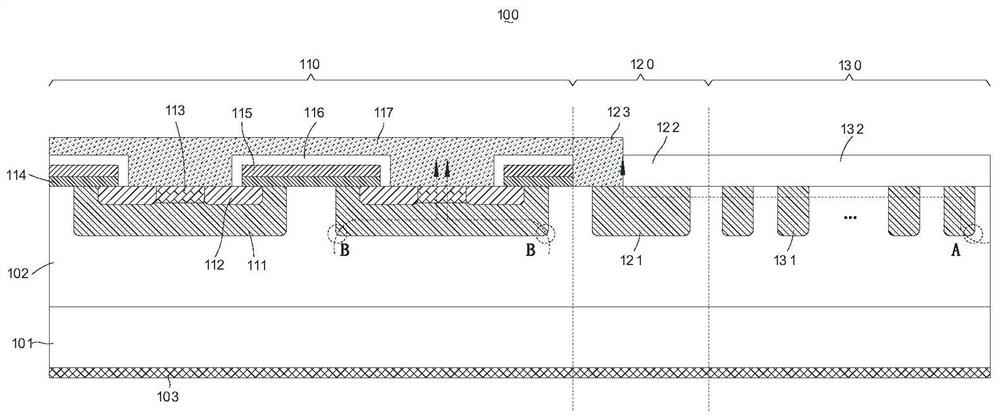

[0053] Such as Figure 4 As shown, the embodiment of the present disclosure provides a power semiconductor device 200 , including a substrate 201 , an epitaxial layer 202 , a drain metal layer 203 , an active region 210 , a transition region 220 and a terminal region 230 .

[0054] Exemplarily, the substrate 201 is a silicon carbide substrate or a silicon substrate of the first conductivity type. The resistivity of the substrate 201 is 0.01 to 0.03 Ω·cm, and the thickness is 200 to 400 μm.

[0055] The epitaxial layer 202 is an epitaxial layer of the first conductivity type and is located above the substrate 201 . The ion doping concentration of the epitaxial layer 202 is 5e14 to 5e16 cm -3 . The doping concentration and thickness of the epitaxial layer 202 are adjusted according to different device withstand voltage capabilities.

[0056] The drain metal layer 203 is located under the substrate 201 and forms an ohmic contact with the substrate 201 .

[0057] The active r...

Embodiment 2

[0078] On the basis of the first embodiment, this embodiment provides a method for manufacturing a power semiconductor device 200 . Figure 6 It is a schematic flowchart of a manufacturing method of a power semiconductor device 200 shown in an embodiment of the present disclosure. Figure 7-Figure 12 It is a schematic cross-sectional structure formed by related steps of a method for manufacturing a power semiconductor device 200 shown in an embodiment of the present disclosure. Below, refer to Figure 6 and Figure 7-Figure 12 The detailed steps of an exemplary method of the method for manufacturing the power semiconductor device 200 proposed by the embodiment of the present disclosure will be described.

[0079] Such as Figure 6 As shown, the manufacturing method of the power semiconductor device 200 in this embodiment includes the following steps:

[0080] Step S101 : providing a first conductivity type substrate 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com