Preparation method of melt-blown electret polymer filter material

A technology of filter material and electret, which is applied in the field of preparation of melt-blown electret polymer filter material, can solve the problems that the melt-blown cloth filter material cannot inhibit bacteria for a long time and the distribution of filtration effect is uneven, and achieve excellent thermal stability , high-efficiency filtration performance, high-efficiency antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

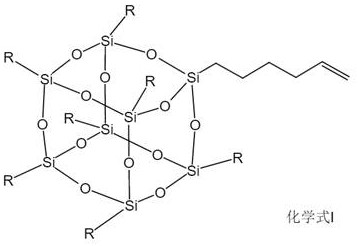

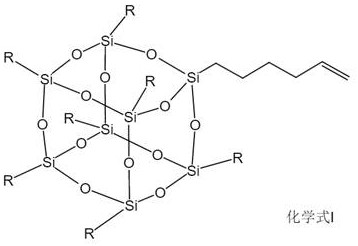

Image

Examples

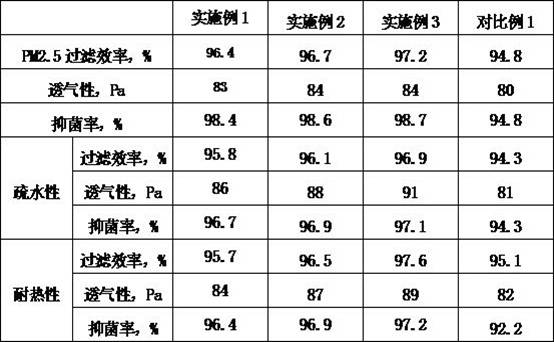

Embodiment 1

[0034] The preparation method of the melt blown electret polymer filter material of the present embodiment, it may further comprise the steps:

[0035] S1: In parts by weight, weigh 100 parts of polypropylene, 0.1 part of dicumyl peroxide, 15 parts of 6-allyl-1,3,5-triazine-2,4-diamine and 10 parts of pH The bacterial agent is added into the high-speed mixer, and after high-speed stirring and mixing, the modification reaction is extruded through the extruder to obtain the modified polypropylene masterbatch.

[0036] S2: Mix the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride obtained in step S1 evenly, after heating and melting, the melt is sprayed out through a spinneret; The mass ratio of the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride is 15:3:100:2.

[0037] S3: Use high-temperature p...

Embodiment 2

[0048] The preparation method of the melt blown electret polymer filter material of the present embodiment, it may further comprise the steps:

[0049] S1: In parts by weight, weigh 100 parts of polypropylene, 0.3 parts of di-tert-amyl peroxide, 20 parts of 4,6-di(allyloxy)-N-butyl-1,3,5-tri Add oxazin-2-amine and 15 parts of antibacterial agent into a high-speed mixer, stir and mix evenly at a high speed, and then carry out modification reaction extrusion through an extruder to obtain a modified polypropylene masterbatch.

[0050] S2: Mix the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride obtained in step S1 evenly, after heating and melting, the melt is sprayed out through a spinneret; The mass ratio of the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride is 20:6:100:5.

[0051] S3: Use hi...

Embodiment 3

[0059] The preparation method of the melt blown electret polymer filter material of the present embodiment, it may further comprise the steps:

[0060] S1: In parts by weight, weigh 100 parts of polypropylene, 0.5 parts of tert-butyl peroxyisobutyrate, and 25 parts of 4,6-diallyloxy-N-octyl-1,3,5-triazine -2-amine and 20 parts of bacteriostatic agent are added into a high-speed mixer, and after high-speed stirring and mixing, the modification reaction is carried out through an extruder to obtain a modified polypropylene masterbatch.

[0061] S2: Mix the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride obtained in step S1 evenly, after heating and melting, the melt is sprayed out through a spinneret; The mass ratio of the modified polypropylene masterbatch, polytetrafluoroethylene masterbatch, polypropylene masterbatch and polypropylene grafted maleic anhydride is 25:8:100:10.

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com