Device and method for online identifying exposed rate of metal matrix when thermal barrier coating is removed through abrasive water jet

An abrasive water jet, metal matrix technology, applied in used abrasive processing devices, abrasive jet machine tools, abrasives, etc., can solve problems such as leakage, affecting detection accuracy, and achieve a consistent recognition accuracy and removal rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

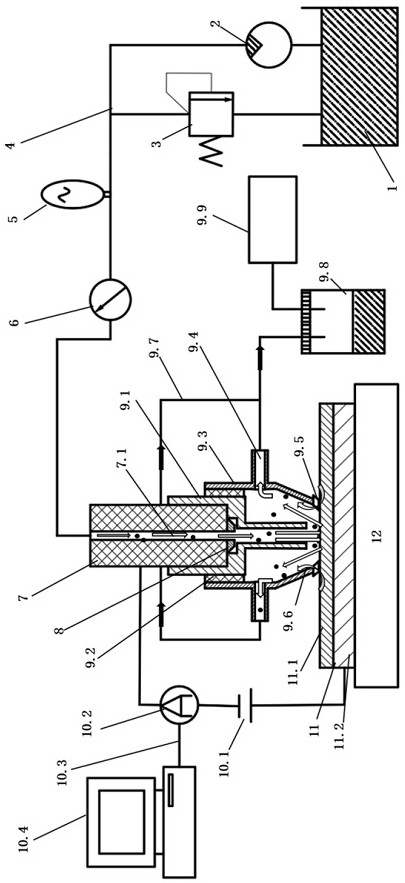

[0026] Such as figure 1 shown.

[0027]An online identification device for the exposed rate of metal substrates when abrasive water jets remove thermal barrier coatings, characterized in that it includes an abrasive working fluid tank 1, an infusion pump 2, an infusion pipeline 4, a jet nozzle 7, a nozzle 8, and a workbench 12. Working fluid return device and weak current detection device; workpiece 11 is installed on workbench 12, workpiece 11 is composed of thermal barrier coating 11.1 and metal substrate 11.2, jet nozzle 7 is connected with infusion pump 2 through infusion pipeline 4, The infusion pump 2 is connected with the working fluid tank 1 and pumps the working fluid in the working fluid tank 1 into the jet nozzle 7, and the infusion pipeline 4 connecting the jet nozzle 7 and the working fluid tank 1 is installed with an overflow valve 3 and a pulsation valve. Damper 5 and pressure gauge 6. The nozzle 8 is installed on the jet nozzle 7, and the jet nozzle 7 is made...

Embodiment 2

[0030] Such as figure 1 shown.

[0031] An on-line identification method for the exposure rate of a metal substrate when removing a thermal barrier coating by erosion, comprising the following steps:

[0032] 1. Clamp the workpiece on the insulating fixture, adjust the relative distance (target distance) between the nozzle and the workpiece surface to be processed to 10mm; add the jet working fluid made of abrasive and tap water into the working fluid tank, and the working fluid The abrasive content in the medium reaches 1% mass fraction, and continuous stirring is required to keep the mixture evenly, and the conductivity value of the abrasive working fluid is detected 350μS / cm; use a nozzle with a diameter of 0.6mm;

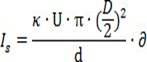

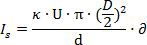

[0033] 2. Connect the cathode of the DC power supply in the current detection device to the jet nozzle, connect the anode of the DC power supply to the metal substrate of the workpiece, and apply a DC voltage of 100V between the jet nozzle and the metal subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com