Resin composition

A resin composition, polyimide resin technology, applied in the direction of electrical components, printed circuits, circuit substrate materials, etc., to achieve the effect of low thermal expansion coefficient and warpage suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0240] Hereinafter, the present invention will be specifically described by way of examples. The present invention is not limited by these examples. In addition, below, unless otherwise specified, "part" and "%" which show an amount mean "mass part" and "mass %", respectively.

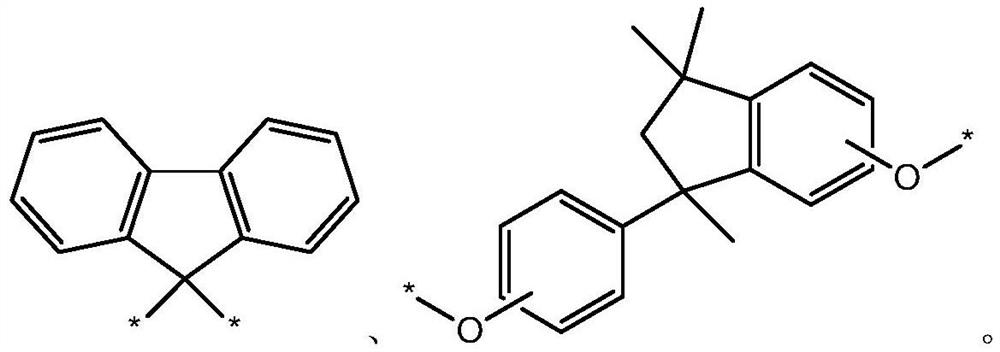

Synthetic example 1

[0241]

[0242] In a 500ml detachable flask equipped with a nitrogen introduction tube and a stirring device, 9.13 g (30 mmoles) of 4-aminobenzoic acid 5-amino-1,1'-biphenyl-2-yl ester, 4,4' -(4,4'-isopropylidenediphenoxy)diphthalic dianhydride 15.61g (30mmol), N-methyl-2-pyrrolidone 94.64g, pyridine 0.47g (6mmol) 10 g of toluene, under a nitrogen atmosphere, at 180° C., carry out imidization reaction for 4 hours while discharging toluene to the outside of the system on the way, thereby obtaining a polyimide solution containing polyimide resin 1 (20% by mass of non-volatile components). In the polyimide solution, precipitation of the synthesized polyimide resin 1 was not observed.

Synthetic example 2

[0243]

[0244] Aromatic tetracarboxylic dianhydride ("BisDA-1000" manufactured by SABIC Japan, 4,4'-(4,4'-isopropylene (diphenoxy) diphthalic dianhydride) 65.0 g, cyclohexanone 266.5 g, and methylcyclohexane 44.4 g, and the solution was heated to 60°C. Next, 43.7 g of dimer diamine (“PRIAMINE 1075” manufactured by Croda Japan Co., Ltd.) and 5.4 g of 1,3-bis(aminomethyl)cyclohexane were added dropwise, and then allowed to cool at 140° C. for 1 hour. Carry out imidization reaction. Thereby, the polyimide solution (30 mass % of non-volatile matter) containing the polyimide resin 2 was obtained. In addition, the weight average molecular weight of the polyimide resin 2 was 25,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com