Rectification separation device for light liquid paraffin and five-stage rectification production process

A light liquid paraffin, rectification separation technology, applied in the direction of distillation separation, petroleum industry, separation methods, etc., to achieve the effect of easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

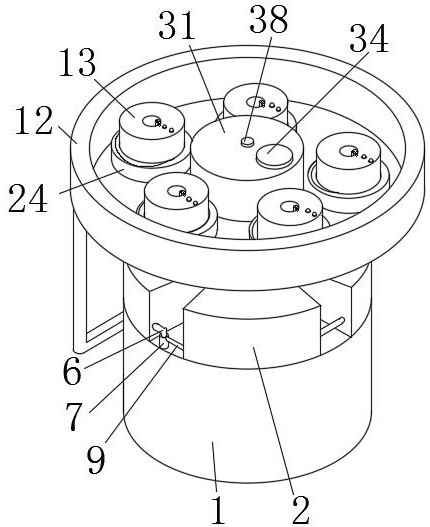

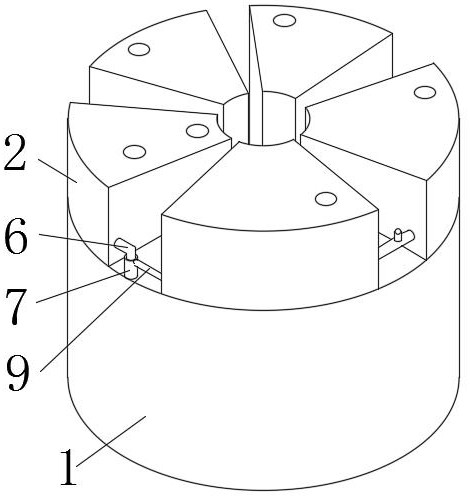

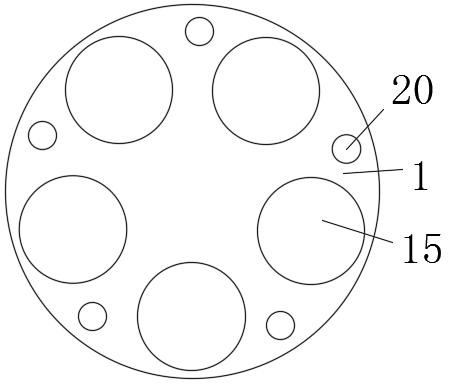

[0042] see Figure 1-12 A rectification and separation device for light liquid paraffin comprises a base 1 and a processing box 2 . The process box 2 is arranged on the top of the base 1 in an annular manner, and a heater 3 is fixedly connected to the inner wall of the process box 2. The structure and working principle of the heater 3 are known, so they will not be described in detail here. The process box 2 One side wall is communicated with a connecting pipe 4, and the outer wall of one end of the connecting pipe 4 is threadedly connected with a blocking block 5, the outer wall of one end of the connecting pipe 4 is provided with a first external thread, and the inner wall of the blocking block 5 is provided with a first external thread. The first internal thread matched with the external thread, while the block 5 is provided with a seal, the block 5 is connected to the connecting pipe 4 to play a sealing role, and the other side wall of the processing box 2 is connected wit...

Embodiment 2

[0058] A five-stage rectification production process of light liquid paraffin: liquid wax is used as raw material, and the hydrocarbon component is between C9-C15. After the raw material liquid wax is pressurized by the feed pump from the tank area, it first enters 1# rectification Rectification is carried out in the separation device, and the product is extracted. The heavy fraction is pumped to 2# rectification separation device. After rectification and separation, the product is extracted, and the heavy fraction is pumped to 3# rectification separation device. After rectification separation, The product is extracted, and the heavy fraction is pumped to the 4# rectification separation device. After rectification and separation, the product is extracted, and the heavy fraction is pumped to the 5# rectification separation device. After the rectification separation, the product and environmental protection liquid wax are extracted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com