Light source equipment

A light source and equipment technology, applied in the direction of electric light source, mechanical equipment, lighting and heating equipment, etc., can solve the problems of inability to maintain the polarization state of circularly polarized light, difficulty in original polarization state of incident light, low luminous efficiency of light source equipment, etc., to achieve work The effect of long life, small etendue, and high color rendering index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

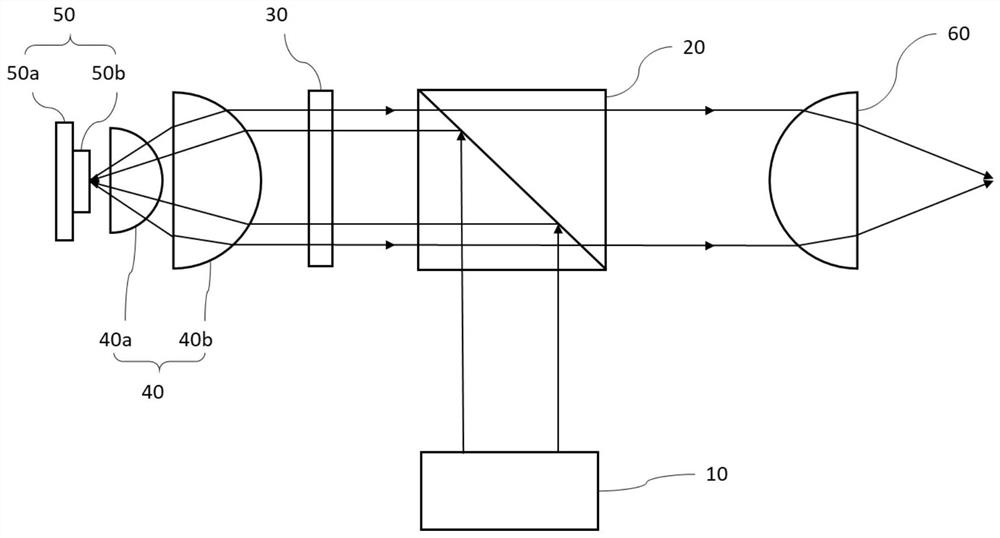

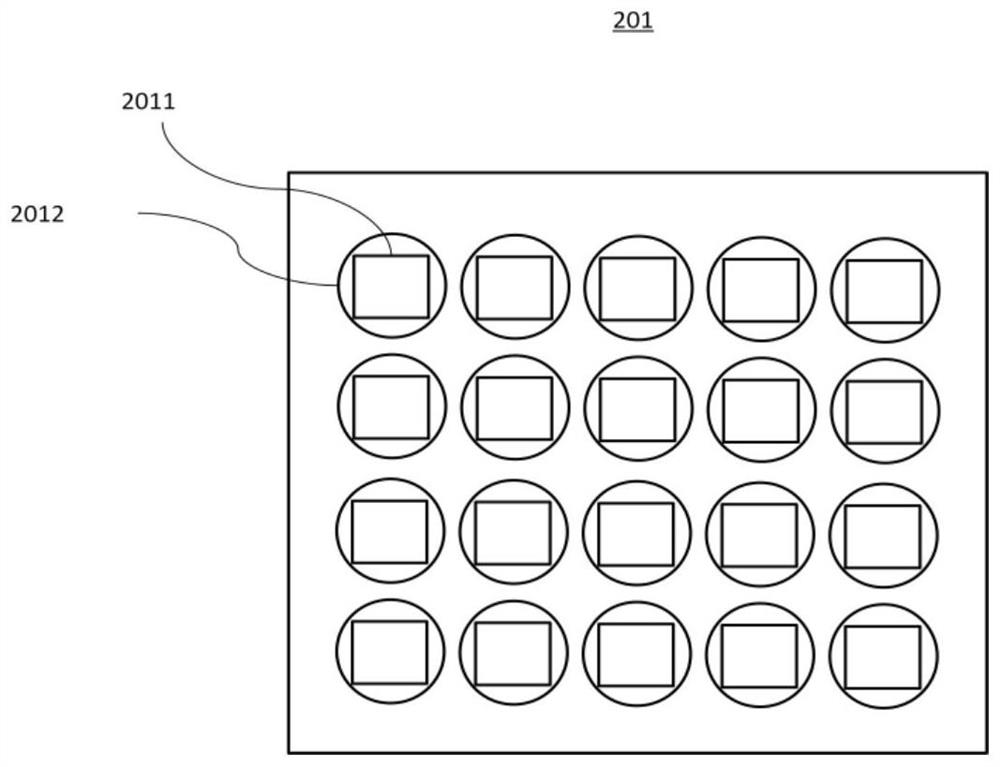

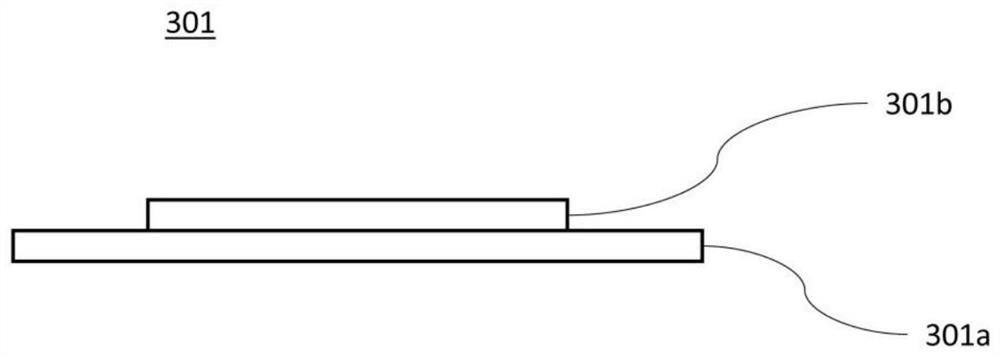

[0079] like Figure 7 As shown, a light source device disclosed in this embodiment includes a light source 701, a light guiding optical system 702, a reflective element 703, a polarizing beam splitter 704, a collecting optical system, a wavelength conversion device 706, and a light concentrating optical system. The polarization beam splitter 704 is a cubic polarization beam splitter, and the transmission area of the reflective element 703 is a light through hole 703a. The light guiding optical system 702 is composed of a positive lens 702a and a positive lens 702b, and the positive lens 702b is located at the light aperture 703a of the reflective element 703 . The collection optical system is composed of a lens group 705 including a lens 705a and a lens 705b. The wavelength converting device 706 includes a reflective layer 706a and a wavelength converting layer 706b disposed on the reflective layer 706a. The condensing optical system is constituted by a focusing lens 707 ....

Embodiment 2

[0082] like Figure 8As shown, a light source device disclosed in this embodiment includes a light source 801, a light guide optical system 802 (consisting of a positive lens 802a and a positive lens 802b), a reflective element 803 (the transmission area is a light hole 803a), and a polarizing beam splitter 804 , a collecting optical system (consisting of a lens group 805 including a lens 805a and a lens 805b), a wavelength conversion device 806, a light collecting optical system (consisting of a focusing lens 807) and a quarter-wave plate 808.

[0083] The difference between this embodiment and Embodiment 1 is that a quarter-wave plate 808 is provided between the polarization beam splitter 804 and the lens group 805 . The blue light of the S polarized light emitted by the light source 801 is guided by the positive lens 802 a and the positive lens 802 b to the polarization beam splitter 804 , and then is reflected by the polarization beam splitter 804 and then goes to the quar...

Embodiment 3

[0085] like Figure 9 As shown, a light source device disclosed in this embodiment includes a light source 901, a light guiding optical system 902 (composed of a positive lens 902a and a positive lens 902b), a reflective element 903, a polarizing beam splitter 904, and a collection optical system (composed of a lens 905a and a positive lens 902b). Lens group 905 of lens 905b), wavelength conversion device 906 (including reflective layer 906a and wavelength conversion layer 906b disposed on reflective layer 906a), light-condensing optical system (composed of a focusing lens 907), quarter-wave Sheet 908 and uniform light optical system.

[0086] The difference between this embodiment and Embodiment 2 lies in the addition of a uniform light optical system. The uniform light optical system is composed of a diffuser 909, and the diffuser 909 is located at the light hole 903a of the reflective element 903 for uniform blue light emitted by the light source 901, thereby reducing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com