Clamping rod extrusion test device and use method

A technique of clamping rods and blocks, applied in measuring devices, using stable tension/pressure to test the strength of materials, and using stable torsion to test the strength of materials, etc. , inability to test and other problems, to achieve the effect of improving the efficiency of factory pressure inspection and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

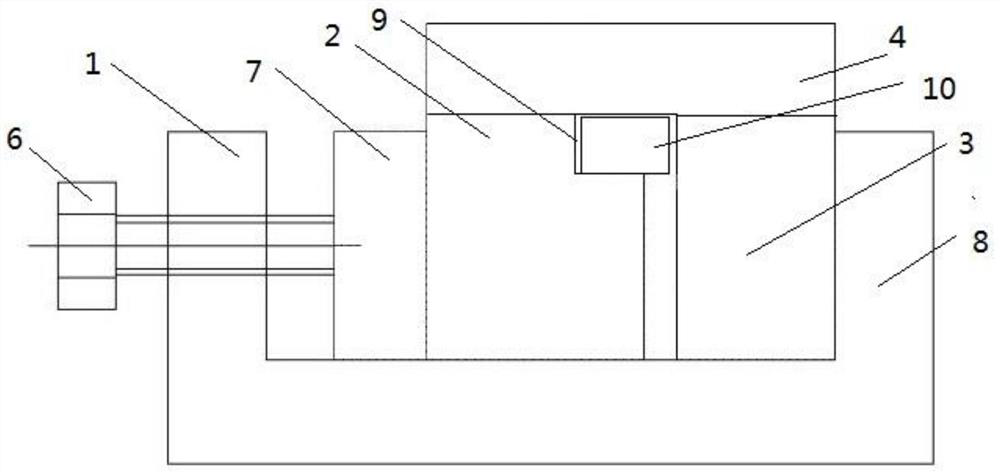

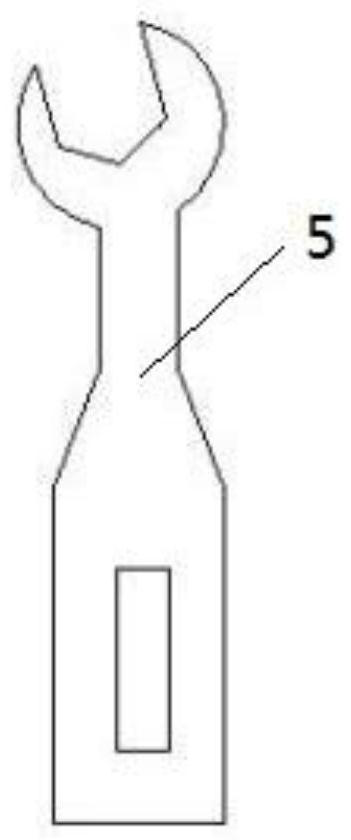

[0029] Such as Figure 1-2 As shown, this embodiment provides a device for clamping rod extrusion testing, including an operation table 1, a clamp block A2, a clamp block B3 and a torque wrench 5. The operation table 1 includes a vise, and the connection between the screw of the vise and the handle is Set as a nut 6, the nut 6 is connected to the torque wrench 5, the clamp block A2 is set on the inside of the movable clamp body 7 of the vise, the clamp block B3 is set on the inside of the fixed clamp body 8 of the vise, and the clamping rod 10 is set on the clamp block A2 and Between clamping block B3.

[0030] A cuboid groove 9 is arranged at the upper end of one side of the clamping block A2 clamping the clamping rod 10, and the clamping rod 10 is arranged in the groove 9, and the clamping rod 10 is clamped by the groove 9 and the clamping block B3 to ensure that the clamping rod 10 Does not flip horizontally after being squeezed.

[0031] The width of the bottom surface o...

Embodiment 2

[0039] A device for clamping rod extrusion test, the structure is as described in embodiment 1, the difference is that the extrusion direction of the clamping rod 10 is consistent with the direction of the layer structure of the clamping rod 10, and the fragility of the clamping rod Test the direction of the layer structure to ensure that the minimum bearing pressure of the clamping rod meets the standard.

Embodiment 3

[0041] A device for clamping rod extrusion test, the structure is as described in embodiment 1, the difference is that clamp block A2, clamp block B3 and clamp block C4 are all cuboids, clamp block A, clamp block B and clamp block C They are all made of die steel, which is not easily deformed, and the processing parallelism is 0.02mm, which ensures that the force on the clamping rod is even and avoids affecting the test results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com