All-solid-state electrochromic device taking lithium aluminum silicate as electrolyte layer and preparation method of all-solid-state electrochromic device

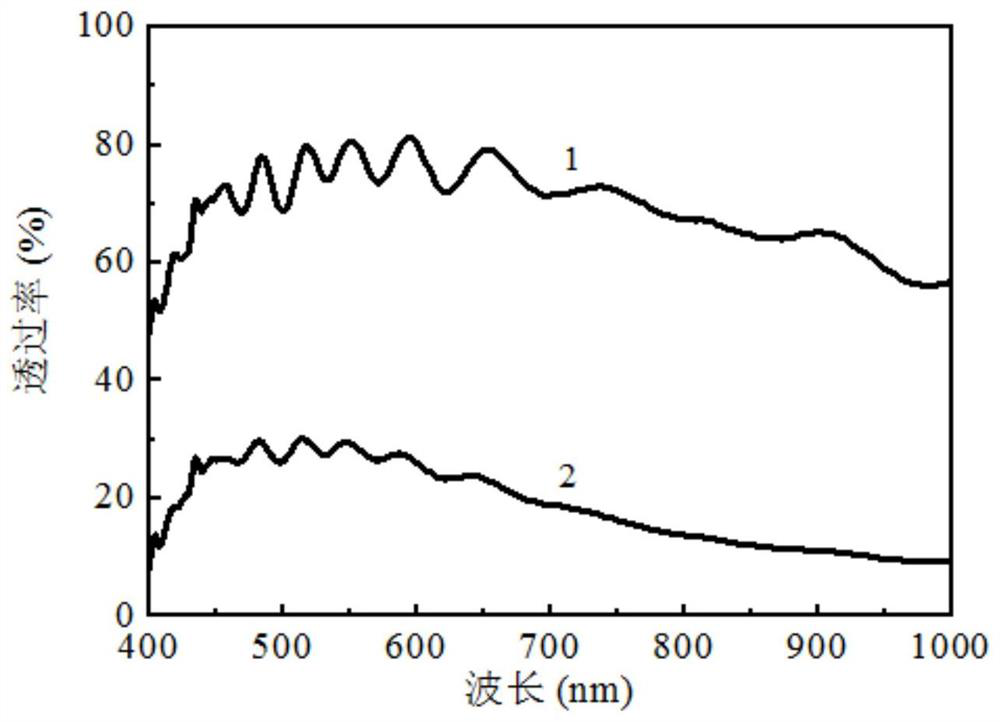

A technology of electrochromic devices and electrolyte layers, applied in instruments, nonlinear optics, optics, etc., can solve the problems of high manufacturing cost, small device transmittance modulation range, slow coloring and fading response speed, etc., and achieve stable chemical properties , excellent stability, the effect of improving the adjustment range and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

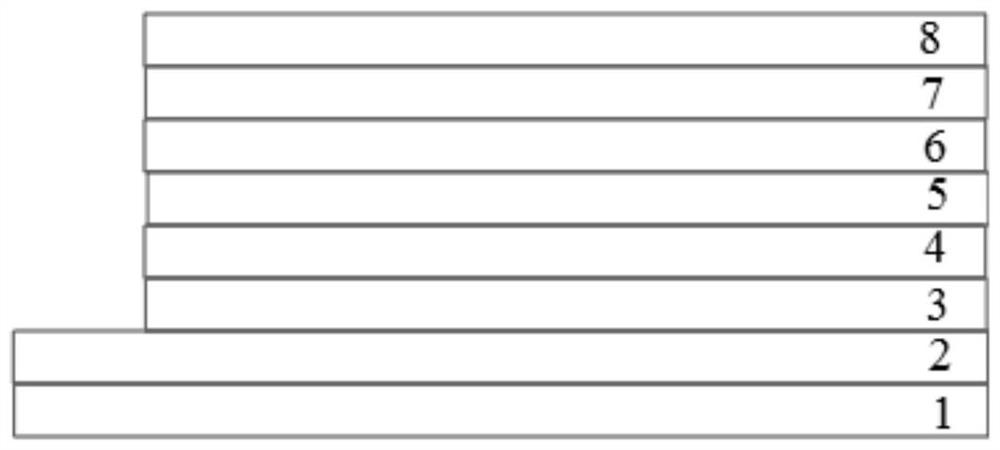

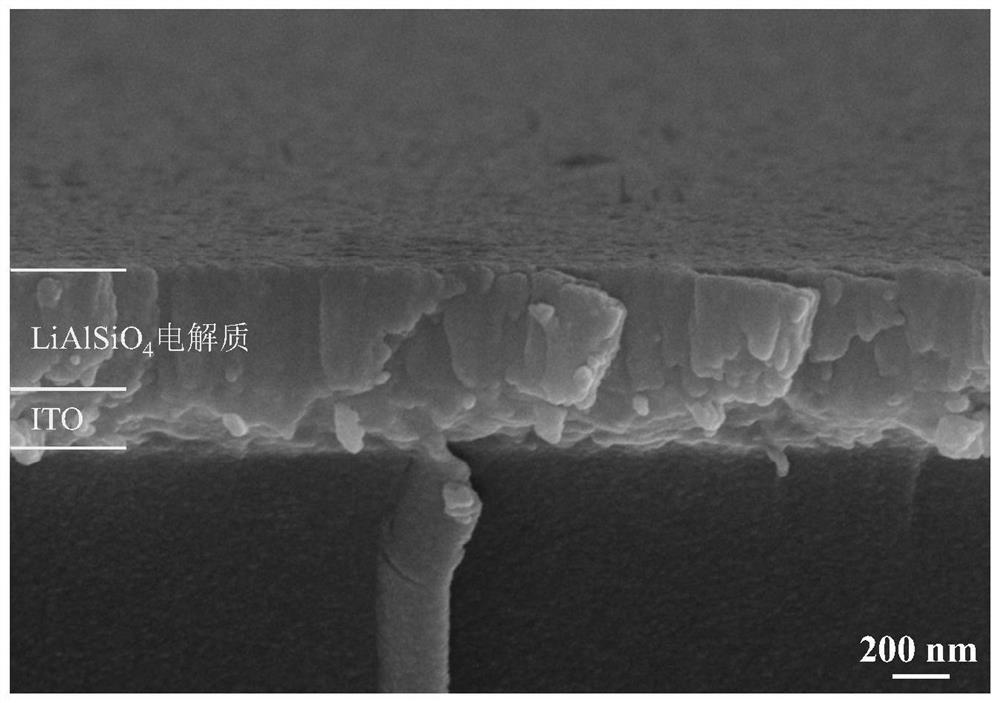

[0029] Embodiment 1: An all-solid-state electrochromic device with lithium aluminum silicate as the electrolyte layer consists of a base, a lower transparent conductive layer, an ion storage layer, a lower protective layer, an electrolyte layer, and an upper protective layer that are sequentially arranged from bottom to top. layer, an electrochromic layer and an upper transparent conductive layer; the electrolyte layer is LiAlSiO 4 ; The lower protective layer is Si 3 N 4 or ZrO 2 ; The upper protective layer is Si 3 N 4 or ZrO 2 .

specific Embodiment approach 2

[0030] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the substrate is a rigid substrate or a flexible substrate; the rigid substrate is silicon, metal or glass; the flexible substrate is polyethylene terephthalate Ethylene glycol formate or dimethicone. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the lower transparent conductive layer is an ITO layer, an FTO layer, an AZO layer, Ag nanowires or Ag nanoframes. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com