SnO2 modified MoS2 hollow microsphere loaded sulfur positive electrode composite material and application thereof in lithium-sulfur battery

A composite material and sulfur positive electrode technology, applied in the direction of lithium batteries, positive electrodes, battery electrodes, etc., can solve the problems of weak chemical interaction, poor Coulombic efficiency capacity decay, etc., to improve electrochemical performance, promote penetration, excellent electrochemical performance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

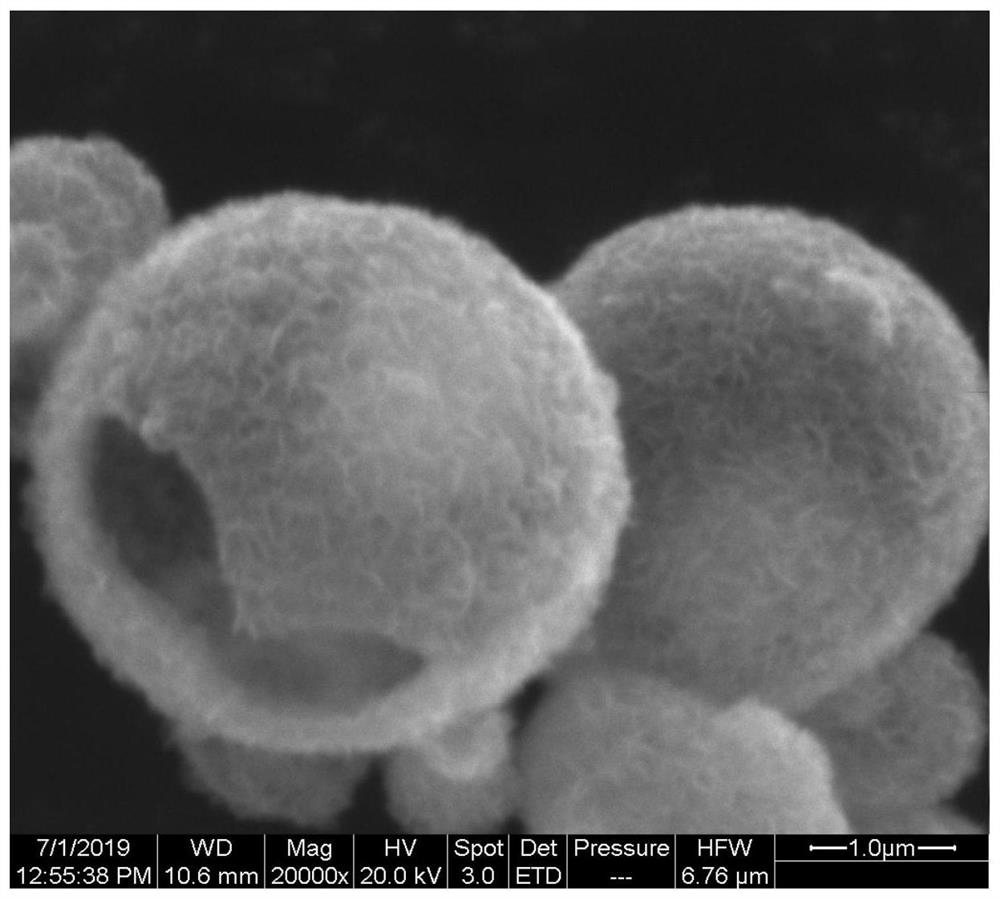

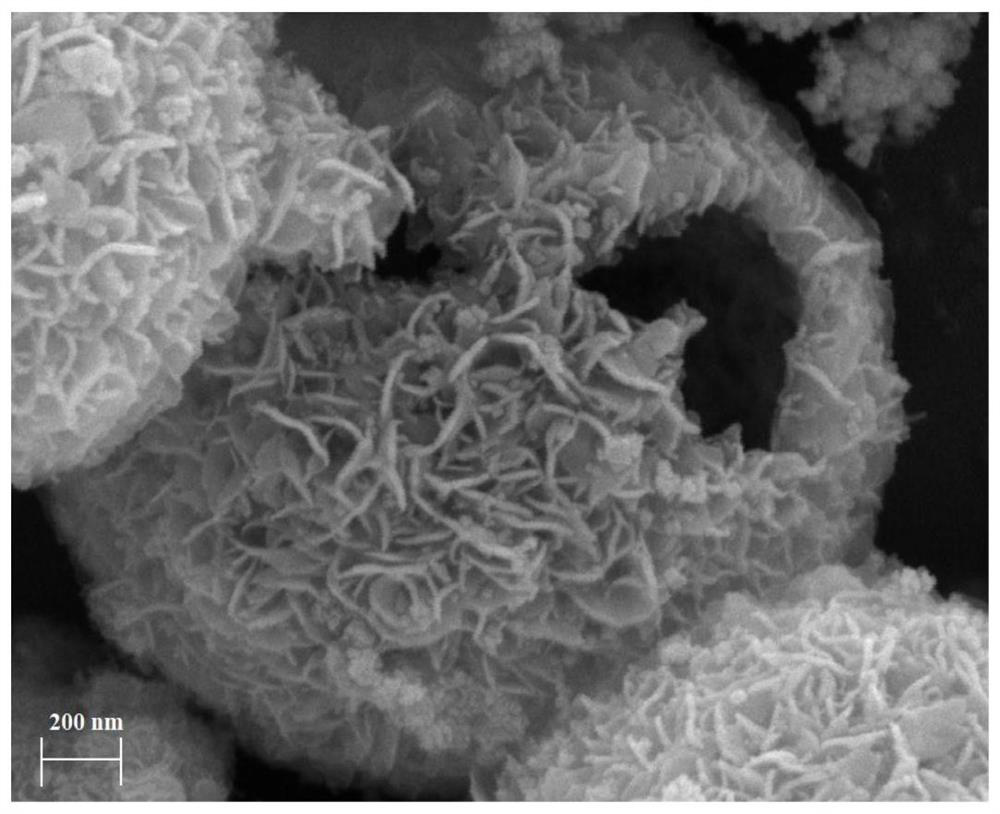

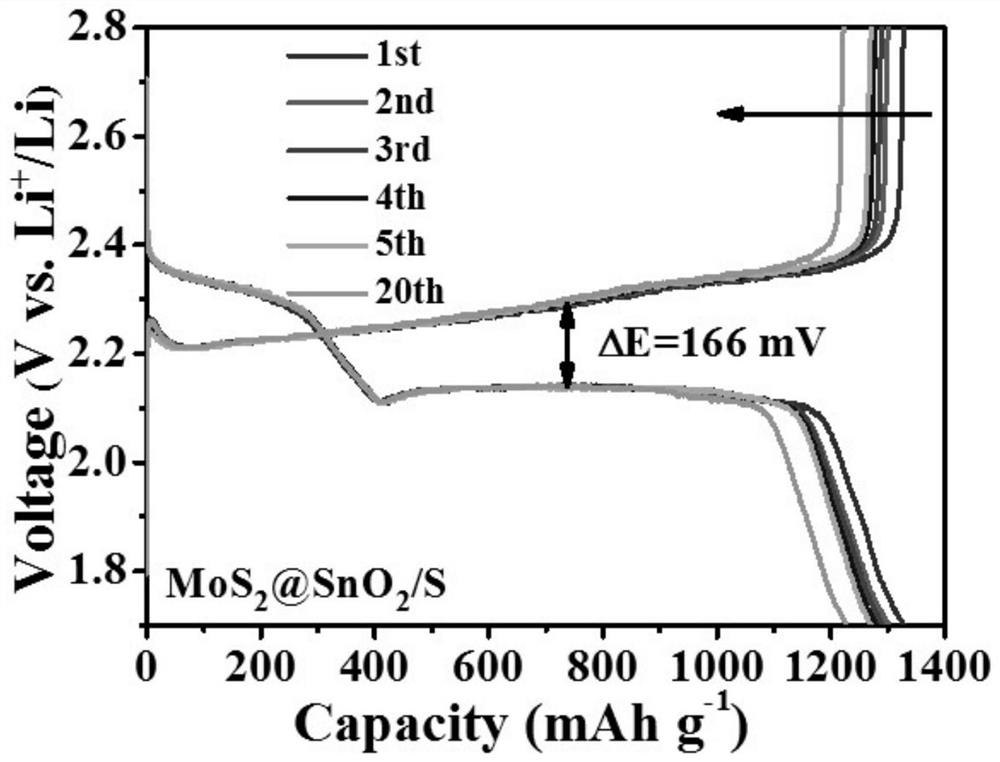

[0055] The present invention SnO 2 Modified MoS 2 The detailed steps of the hollow microsphere-loaded sulfur cathode composite material are as follows:

[0056] 1) MnCO 3 Preparation of microsphere template:

[0057] a. Add 0.01mol of NaHCO 3 Dissolve in 70ml deionized water, and obtain A solution after fully dissolving;

[0058] b. Mix 0.001mol of MnSO 4 ·H 2 O was dissolved in 70ml of deionized water, and 7ml of absolute ethanol was added under the condition of constant stirring, and the B solution was obtained after stirring evenly;

[0059] c. Then, under the condition of constant stirring, slowly pour the obtained A solution into the B solution, seal the container, and then put it into an oven for reaction. The reaction temperature is 60°C, and the reaction time is 4h. After the reaction, collect the white precipitate Wash and dry in vacuum (washing is to use deionized water and absolute ethanol to wash alternately until the supernatant obtained is neutral; when va...

Embodiment 2

[0069] The present invention SnO 2 Modified MoS 2 The detailed steps of the hollow microsphere-loaded sulfur cathode composite material are as follows:

[0070] 1) MnCO 3 Preparation of microsphere template:

[0071] a. Add 0.01mol of NaHCO 3 Dissolve in 70ml deionized water, and obtain A solution after fully dissolving;

[0072] b. Mix 0.001mol of MnSO 4 ·H 2 O was dissolved in 70ml of deionized water, and 7ml of absolute ethanol was added under the condition of constant stirring, and the B solution was obtained after stirring evenly;

[0073] c. Then, under the condition of constant stirring, slowly pour the obtained A solution into the B solution, seal the container, and then put it into an oven for reaction. The reaction temperature is 60°C, and the reaction time is 4h. After the reaction, collect the white precipitate Wash and dry in vacuum (washing is to use deionized water and absolute ethanol to wash alternately until the supernatant obtained is neutral; when va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible capacity | aaaaa | aaaaa |

| Initial discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com