A kind of high-efficiency flotation method of talc inhibitor and talc-containing molybdenum ore

A talc-molybdenum and inhibitor technology is applied in the field of high-efficiency flotation of talc-inhibitor and talc-containing molybdenum ore, which can solve the recovery rate of molybdenum concentrate, low grade, difficulty in reuse of tailings water, interference with molybdenum mineral flotation, etc. problems, to achieve the effect of improving grade, improving utilization rate, and efficient separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

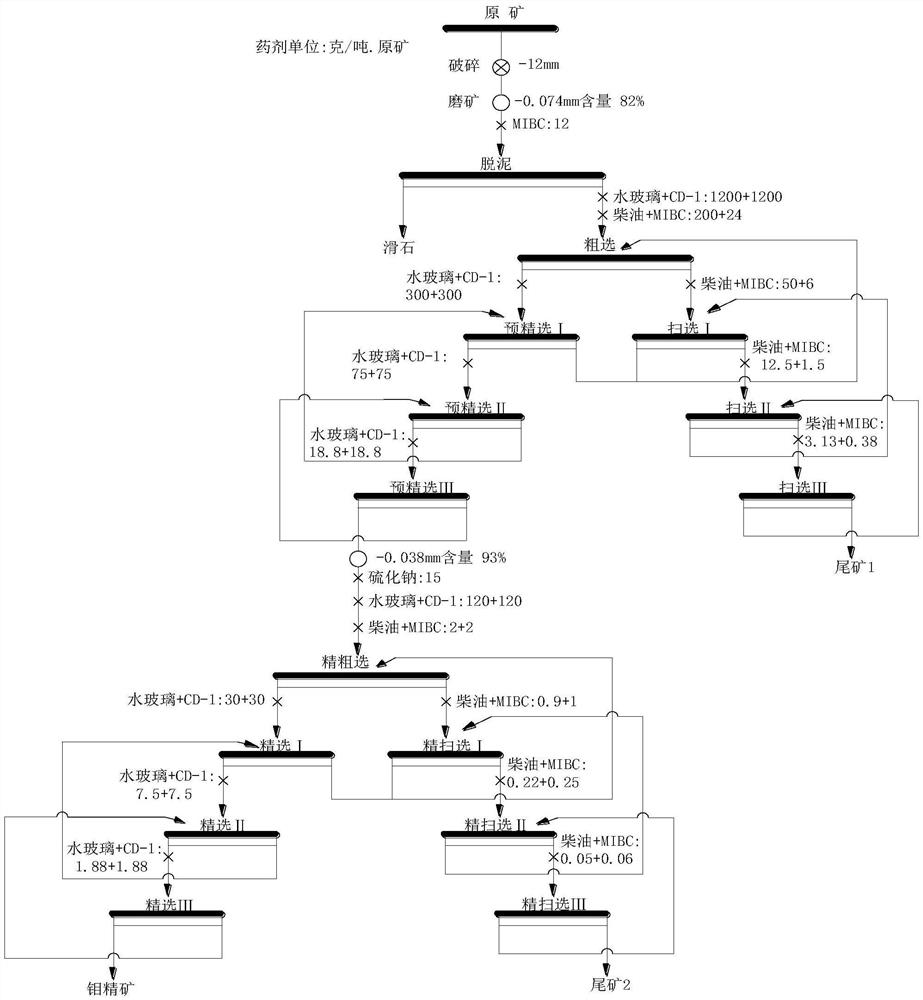

[0051] see figure 1 As shown, the present embodiment provides a kind of high-efficiency flotation method of talc-containing molybdenum ore, molybdenum raw ore contains Mo 0.14%, talc 16%, S 0.64%, Fe 10.56%, SiO 2 46.82%.

[0052] Specific steps are as follows:

[0053] S1. Grinding and classification: The raw ore in the mining area is crushed in three stages to below 12mm, and then the crushed ore is fed into a ball mill for grinding. The grinding products are classified by a cyclone to obtain 82% of the fineness below 0.074mm. % cyclone classification overflow product, the hydrocyclone classification overflow slurry adjustment to a concentration of 30% to 35%, fed into the flotation talc removal operation.

[0054] S2. Talc removal: Since the talc content is higher than 15%, the graded overflow of the cyclone is fed into the strong mixing tank, and methyl isobutyl carbinol (MIBC) is added in the strong mixing tank as a talc collector. The amount is 12 grams / ton of raw or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com