A kind of selection method of lead-zinc sulfide ore

A lead and zinc sulfide and lead roughing technology, applied in flotation, solid separation and other directions, can solve the problems of low recovery rate of lead and zinc, and achieve the effect of improving grade and recovery rate, reducing dosage and good flotation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

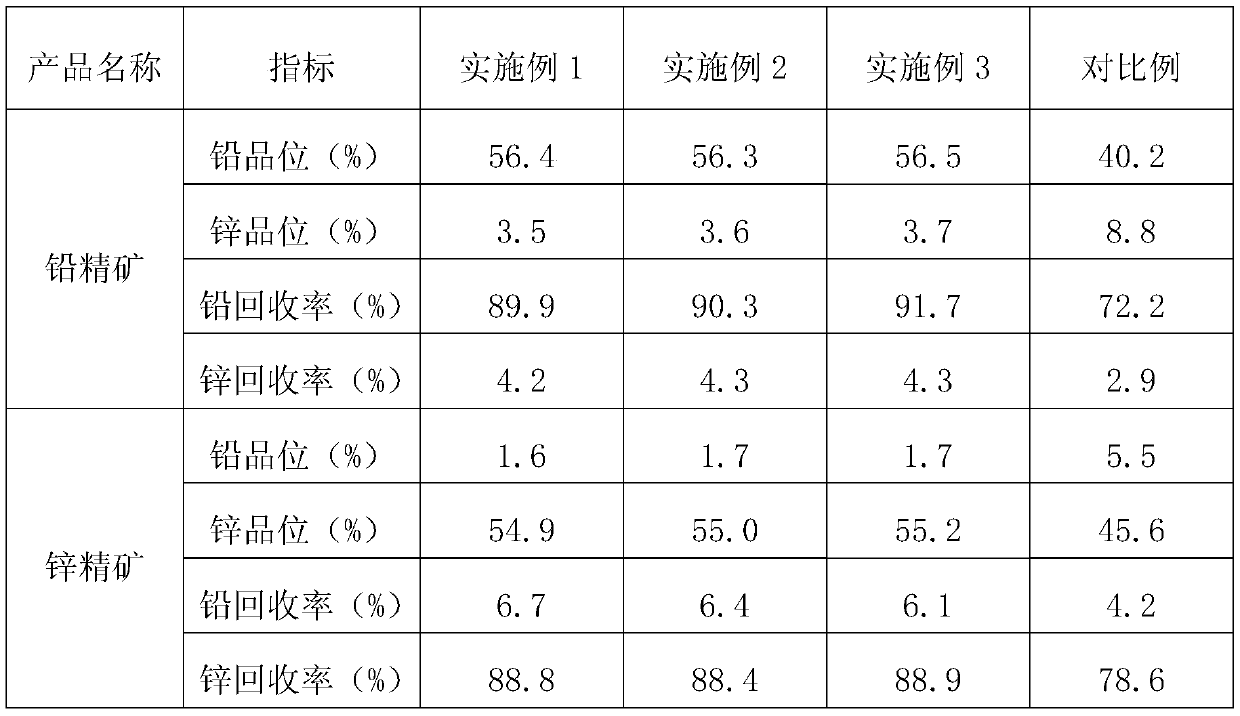

Embodiment 1

[0028] A method for selecting lead-zinc sulfide ore, comprising the following steps:

[0029] (1) Raw ore grinding: Finely grind the selected raw ore to obtain a slurry with an abrasive particle size of -80 μm, accounting for 70%.

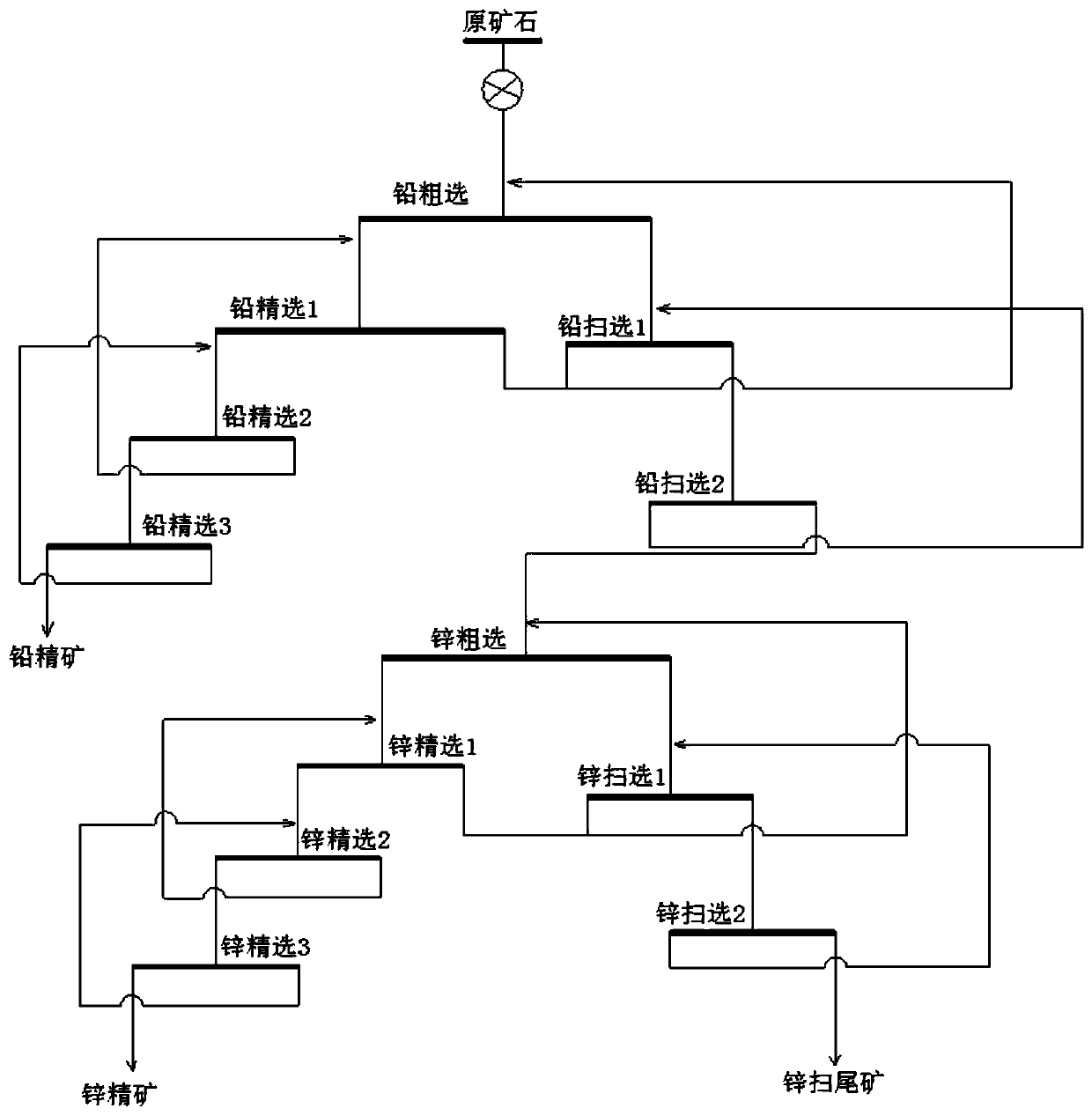

[0030] (2) Lead flotation: the pulp obtained in step (1) is subjected to one lead roughing, three lead concentration and two lead sweeping to obtain lead concentrate and lead sweeping tailings. During lead flotation, the mass percentage concentration of the pulp is adjusted to 30%, the pH is adjusted to 9, and the lead ore produced in the lead flotation process is returned to the previous step process in sequence.

[0031] The following agents are added during the lead roughing process: lime 1800g / t, calcium hypochlorite 600g / t, zinc sulfate 800g / t, sodium sulfite 400g / t, sodium sulfide 300g / t, dimethyl dicarbonate 20g / t, Ethiazide 60g / t, butyl xanthate 40g / t, aniline black medicine 20g / t, diphenylaminodithiophosphoric acid 20g / t and sodium carbon...

Embodiment 2

[0039] A method for selecting lead-zinc sulfide ore, comprising the following steps:

[0040] (1) Raw ore grinding: Finely grind the selected raw ore to obtain an ore slurry with an abrasive particle size of -80 μm, accounting for 75%.

[0041] (2) Lead flotation: the pulp obtained in step (1) is subjected to one lead roughing, three lead concentration and two lead sweeping to obtain lead concentrate and lead sweeping tailings. During lead flotation, the mass percentage concentration of the pulp is adjusted to 40%, the pH is adjusted to 12, and the lead ore produced in the lead flotation process is returned to the previous process in sequence.

[0042]The following agents are added during the lead roughing process: lime 2000g / t, calcium hypochlorite 1000g / t, zinc sulfate 1000g / t, sodium sulfite 600g / t, sodium sulfide 600g / t, dimethyl dicarbonate 40g / t, Ethiazide 80g / t, butyl xanthate 60g / t, aniline black medicine 40g / t, diphenylaminodithiophosphoric acid 40g / t and sodium carb...

Embodiment 3

[0050] A method for selecting lead-zinc sulfide ore, comprising the following steps:

[0051] (1) Raw ore grinding: Finely grind the selected raw ore to obtain an ore slurry with an abrasive grain size of -80 μm, accounting for 72%.

[0052] (2) Lead flotation: the pulp obtained in step (1) is subjected to one lead roughing, three lead concentration and two lead sweeping to obtain lead concentrate and lead sweeping tailings. During lead flotation, the mass percentage concentration of the pulp is adjusted to 35%, the pH is adjusted to 10, and the lead ore produced in the lead flotation process is returned to the previous step process in sequence.

[0053] The following agents are added during the lead roughing process: lime 1900g / t, calcium hypochlorite 800g / t, zinc sulfate 900g / t, sodium sulfite 500g / t, sodium sulfide 450g / t, dimethyl dicarbonate 30g / t, Ethiazide 70g / t, butyl xanthate 50g / t, aniline black medicine 30g / t, diphenylaminodithiophosphoric acid 30g / t and sodium car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com