Heat-preservation and heat-insulation fireproof plate and preparation method and application thereof

A technology of thermal insulation and fireproof board, which is applied in the field of thermal insulation materials, can solve the problems of high cost, complicated preparation process, fragile perlite insulation board, etc., and achieve the effects of low price, lower water absorption rate and lower porosity rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

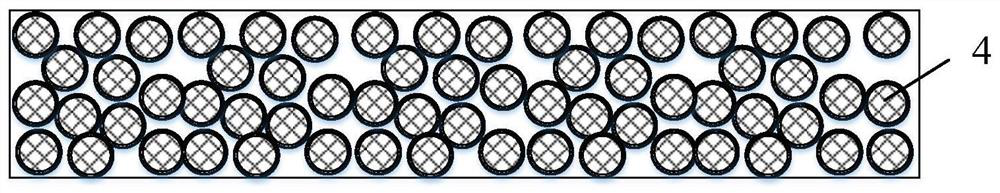

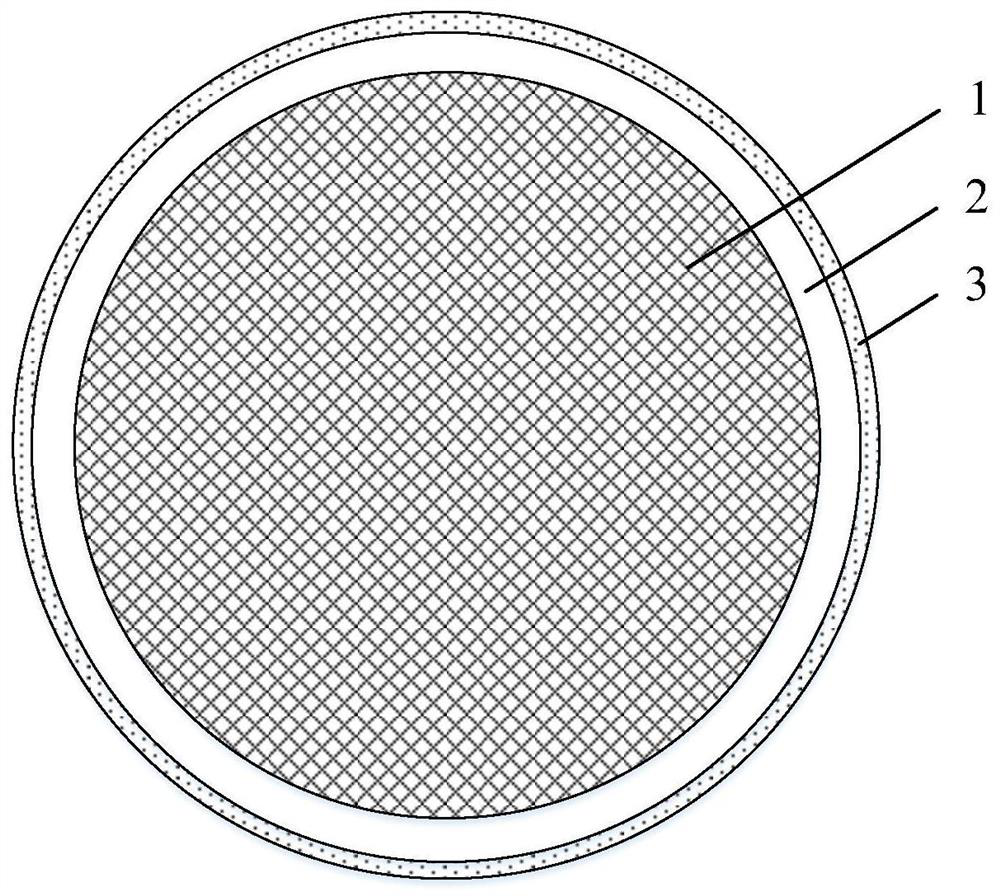

[0071] The present invention also provides a method for preparing a heat-insulating fireproof board, which is used to prepare the above-mentioned heat-insulating fireproof board. The above-mentioned preparation method includes the following steps:

[0072] Step A: mixing foamed glass particles, cement, adhesive and water to obtain a mixture;

[0073] Step B: making boards and curing the mixture to obtain thermal insulation and fireproof boards.

[0074] Compared with the prior art, the beneficial effects of the preparation method of the thermal insulation and fireproof board provided by the present invention are basically the same as those of the above thermal insulation and fireproof board, and will not be repeated here.

[0075] In order to ensure the uniformity of mixing of foamed glass particles, cement, adhesive and water, above-mentioned step A comprises the following steps:

[0076] Step I: mixing cement, bonding agent and water to obtain bonding material;

[0077] St...

Embodiment 1

[0110] The preparation method of the foamed glass particles provided in this embodiment comprises the following steps:

[0111] Step a: mixing 5 g of urea with 320 g of water glass to obtain a mixture, the particle size of which is 2.5 to 2.8 mm;

[0112] Step b: Using high-pressure spraying, spray the mixture into 1000g of glass powder and stir and mix, the stirring speed is 0.5rad / s, the pressure of high-pressure spray is 2000pa, and the addition time of the mixture is 6min to obtain mixed particles;

[0113] Step c: tile the mixed particles, remove the mixed particles with a particle size larger than 15 mm, crush the mixed particles with a particle size larger than 15 mm and remix them into the mixed particles, and dry them naturally for 20 hours;

[0114] Step d: drying the mixed particles after drying, the drying temperature is 500°C, and the drying time is 8 minutes;

[0115] Step e: sieving and grading the dried mixed granules, and dividing the mixed granules into mixe...

Embodiment 2

[0122] The preparation method of the foamed glass particles provided in this embodiment comprises the following steps:

[0123] Step a: mixing 8 g of urea with 450 g of water glass to obtain a mixture, the particle size of which is 2.5 to 2.8 mm;

[0124] Step b: Using high-pressure spraying, spray the mixture into 1000g of glass powder and stir and mix. The stirring speed is 1.0rad / s, the pressure of the high-pressure spray is 3000pa, and the addition time of the mixture is 10min to obtain mixed particles;

[0125] Step c: tile the mixed particles, remove the mixed particles with a particle size larger than 15 mm, crush the mixed particles with a particle size larger than 15 mm and remix them into the mixed particles, and dry them naturally for 10 hours;

[0126] Step d: drying the mixed particles after drying, the drying temperature is 350°C, and the drying time is 5 minutes;

[0127] Step e: sieving and grading the dried mixed granules, and dividing the mixed granules into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com