Novel asphalt pavement regeneration method

A technology of asphalt pavement and asphalt rejuvenation agent, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problem of volatilization of harmful components in asphalt fume, and achieve the goal of improving reusability, performance, and aggregate volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

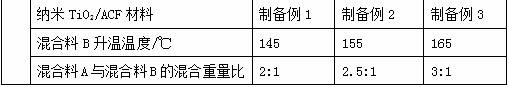

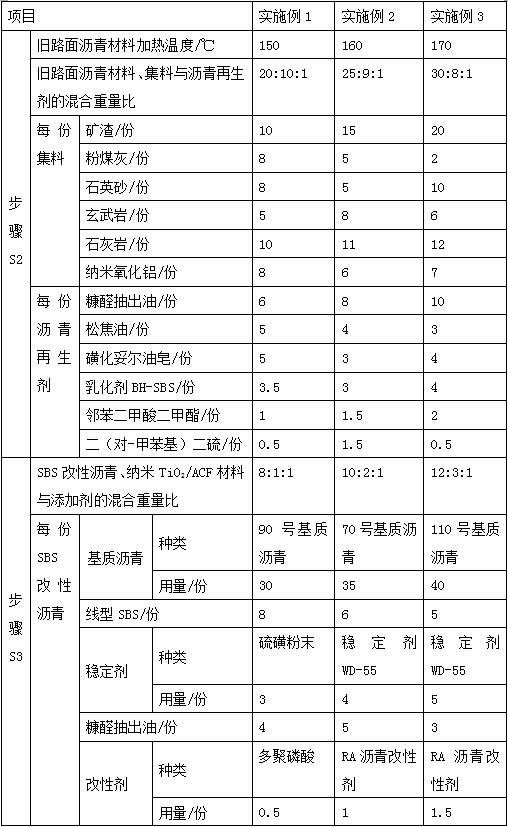

Examples

preparation example 1

[0056] Nano-TiO 2 / ACF material is prepared by the following steps:

[0057]Step A: Take 10 parts by weight of activated carbon fibers, condense and reflux with isopropanol for 25 minutes at a temperature of 82° C.; wherein the fiber diameter of the activated carbon fibers is 5 μm;

[0058] Step B: adding the activated carbon fiber after the condensing and reflux treatment in step A to 80 parts by weight of nitric acid solution, in an oil bath at a temperature of 120° C. for 4 hours, then filtering, and repeatedly washing the filtered activated carbon fiber with deionized water, Modified activated carbon fibers are obtained; wherein the massfraction of nitric acid solution is 60%;

[0059] Step C: Take 5 parts by weight of nano-titanium dioxide, add it to 100 parts by weight of isopropanol aqueous solution, and ultrasonically disperse it for 15 minutes at a frequency of 15000 Hz to obtain a dispersion; wherein the particle size of nano-titanium dioxide is 20 nm, and the isopr...

preparation example 2

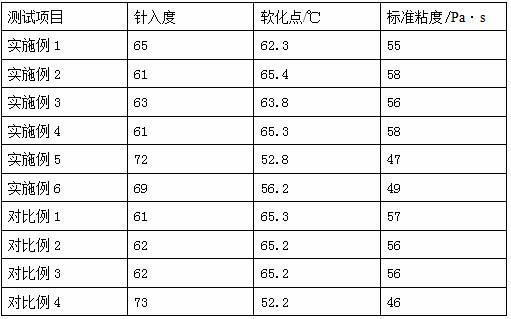

[0062] The difference between Preparation Example 2 and Preparation Example 3 and the above-mentioned Preparation Example 1 lies in the amount of materials and process conditions, see Table 2 below for details:

[0063] Table 2 Condition parameter table of preparation examples 1-3

[0064]

preparation example 4

[0066] The difference between this preparation example and the above-mentioned preparation example 2 is: the activated carbon fiber is treated with microwave heating, and the specific steps are as follows:

[0067] Step A: Take 13 parts by weight of activated carbon fibers, condense and reflux with isopropanol for 23 minutes at a temperature of 83° C.; wherein the fiber diameter of the activated carbon fibers is 10 μm;

[0068] Step B: Put the activated carbon fiber after the condensing and reflux treatment in step A into 800W, 150V microwave radiation treatment for 3 minutes, take it out, and prepare the modified activated carbon fiber;

[0069] Step C: Take 8 parts by weight of nano-titanium dioxide, add it to 105 parts by weight of isopropanol aqueous solution, and ultrasonically disperse it for 13 minutes at a frequency of 16000 Hz to obtain a dispersion; wherein the particle size of nano-titanium dioxide is 30 nm, and the isopropanol aqueous solution The mass fraction is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com