A kind of preparation method of temperature-resistant and salt-resistant foam discharge agent

A technology of temperature resistance, salt resistance and foam discharge agent, which is applied in the field of oil and gas field chemistry, can solve the problems of poor foaming and foam stabilization performance of foam discharge agent, and achieve the effects of large foam volume, easy control and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

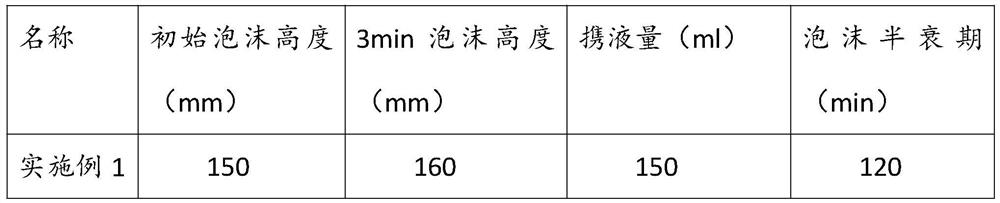

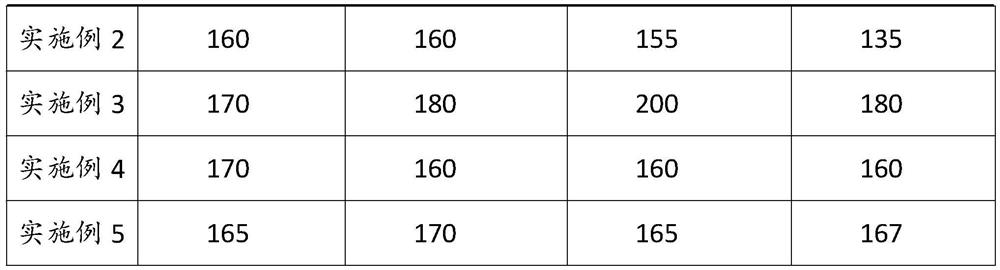

Examples

Embodiment 1

[0017] Add fatty acid methyl ester sodium sulfonate (MES) into the three-necked flask, heat and melt, blow in nitrogen to exhaust oxygen, and then add N,N-dimethyl-1,3-propane dropwise according to the mass ratio of 1:3 Diamine, then condensed and refluxed, stirred evenly at a speed of 1800r / min, and reacted at 180°C for 18 hours to obtain a solid; the resulting solid was recrystallized with a 10% sodium chloride solution, filtered, and dried. That is, the foam discharge agent of Example 1 is prepared.

Embodiment 2

[0019] Add fatty acid methyl ester sodium sulfonate (MES) into the three-necked flask, heat and melt, blow in nitrogen to exhaust oxygen, and then add N,N-dimethyl-1,3-propane dropwise according to the mass ratio of 1:3.5 Diamine, then condensed and refluxed, stirred evenly at a speed of 1800r / min, and reacted at 180°C for 18 hours to obtain a solid; the resulting solid was recrystallized with a 10% sodium chloride solution, filtered, and dried. That is, the foam discharge agent of Example 2 is prepared.

Embodiment 3

[0021] Add fatty acid methyl ester sodium sulfonate (MES) into the three-necked flask, heat and melt, blow in nitrogen to exhaust oxygen, and then add N,N-dimethyl-1,3-propane dropwise according to the mass ratio of 1:4 Diamine, then condensed and refluxed, stirred evenly at a speed of 1800r / min, and reacted at 180°C for 18 hours to obtain a solid; the resulting solid was recrystallized with a 10% sodium chloride solution, filtered, and dried. That is, the foam discharge agent of Example 3 is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com