Non-contact ultra-low temperature sensing up-conversion nanoprobe and preparation method and application of non-contact ultra-low temperature sensing up-conversion nanoprobe

A non-contact, nano-probe technology, applied in thermometers, chemical instruments and methods, thermometers with physical/chemical changes, etc., can solve the problems of sensitivity, rare earth-doped up-conversion fluorescent probes not suitable for ultra-low temperature ranges, etc. , to achieve the effects of increasing the intensity of fluorescence emission, enhancing the ability to resist interference from environmental factors, and detecting high-sensitivity temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

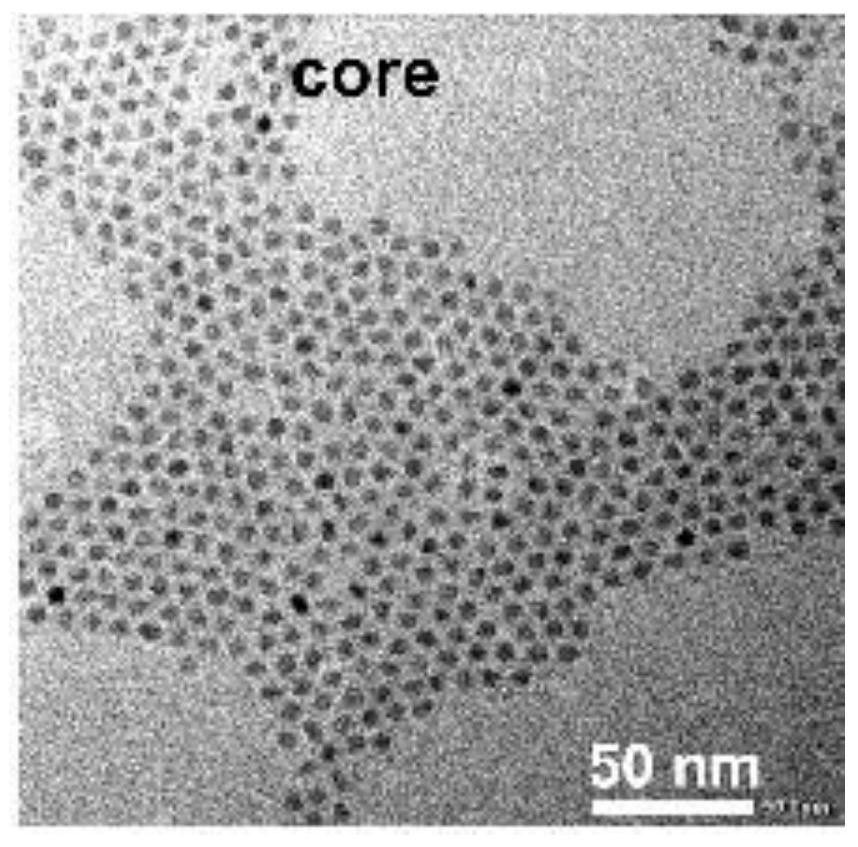

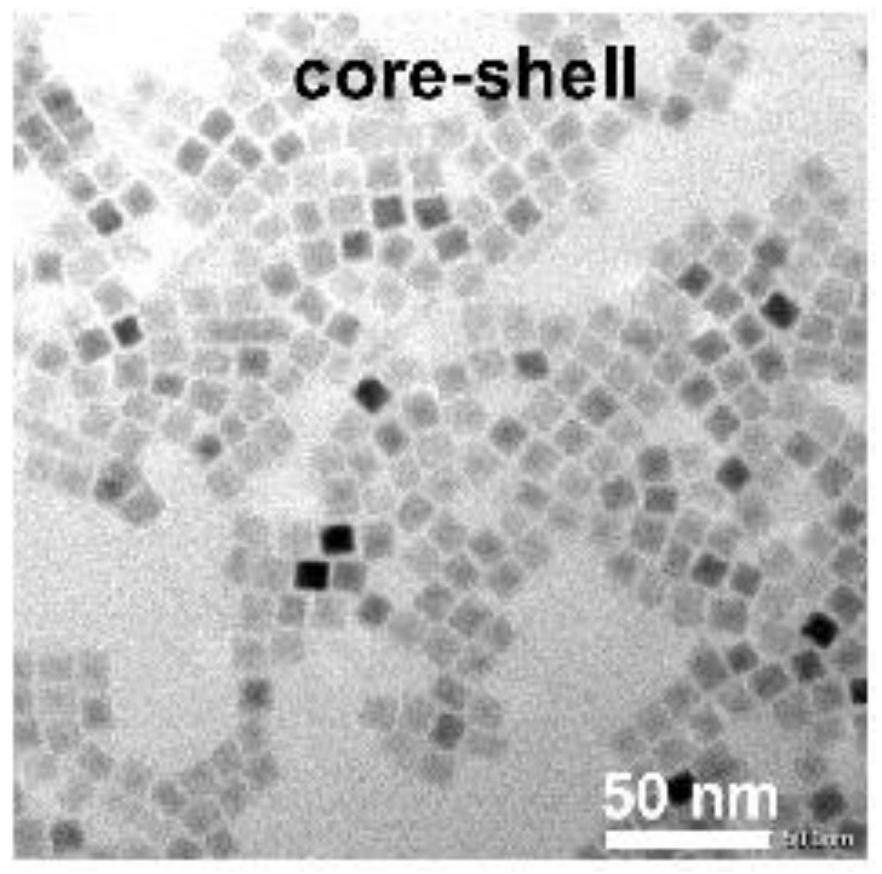

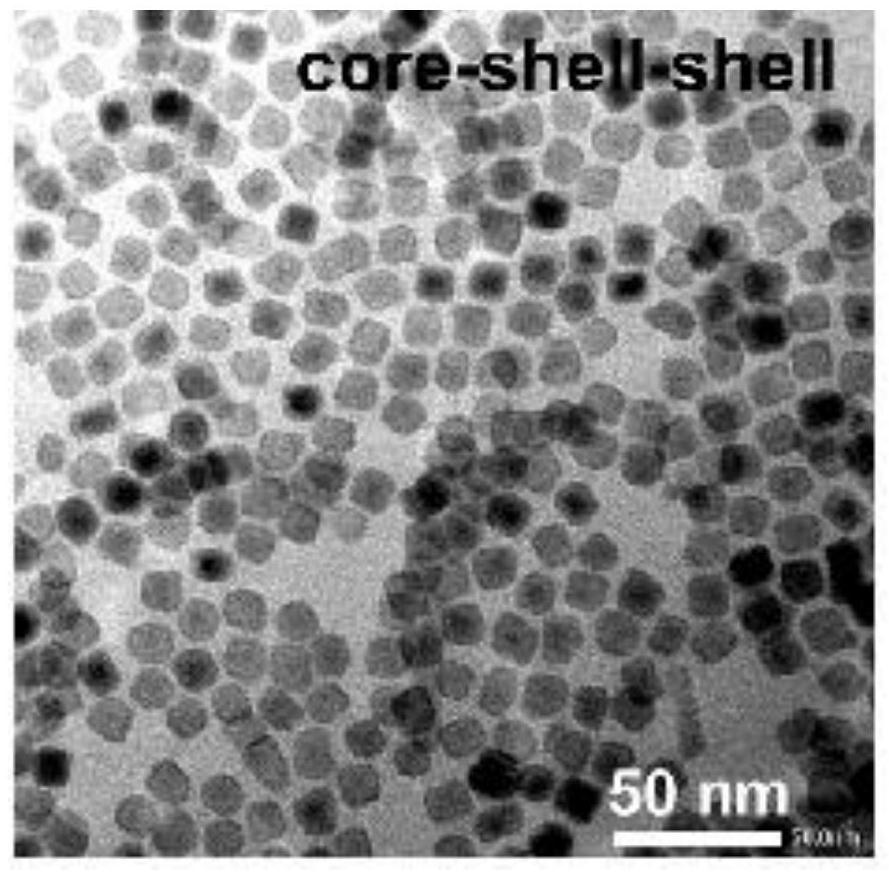

[0055] Example 1: The non-contact ultra-low temperature sensing up-conversion nanoprobe α-NaYF of this example 4 @NaY 0.79 f 4 :Yb 0.20 3+ / Tm 0.01 3+ @CaF 2 The preparation method, carry out according to the following steps:

[0056] 1. Preparation of α-NaYF 4 Nanocrystalline core:

[0057] (1) First take by weighing the yttrium oxide (Yttria) that total amount is 0.5mmol 2 o 3 ) raw materials, and placed in a 100mL three-neck flask, added 5mL of trifluoroacetic acid with a concentration of 50% by mass, and fully stirred at 90°C to completely dissolve the medicine;

[0058] (2) Dry the liquid in the there-necked flask with argon to obtain 1.0mmol yttrium trifluoroacetate [Y(CF 3 COO) 3 ] solid powder, then add 2mmol sodium trifluoroacetate (CF 3 COONa), 8mL oleic acid, 8mL oleylamine and 12mL of octadecene, stir to obtain a mixed solution;

[0059] (3) Heat the mixed solution to 120°C, and blow argon into the mixed solution for 30 minutes under an argon atmosphe...

Embodiment 2

[0082] Example 2: The non-contact ultra-low temperature sensing up-conversion nanoprobe α-NaYF of this example 4 @NaY 0 f 4 :Yb 0.99 3+ / Tm 0.01 3+ @NaYF 4 The preparation method, carry out according to the following steps:

[0083] 1. Preparation of α-NaYF 4 Nanocrystalline Core:

[0084] (1) First take by weighing the yttrium oxide (Yttria) that total amount is 0.5mmol 2 o 3 ) raw materials, and placed in a 100mL three-neck flask, added 5mL of trifluoroacetic acid with a concentration of 50% by mass, and fully stirred at 90°C to completely dissolve the medicine;

[0085] (2) Dry the liquid in the there-necked flask with argon to obtain 1.0mmol yttrium trifluoroacetate [Y(CF 3 COO) 3 ] solid powder, then add 2mmol sodium trifluoroacetate (CF 3 COONa), 8mL oleic acid, 8mL oleylamine and 12mL of octadecene, stir to obtain a mixed solution;

[0086] (3) Heat the mixed solution to 120°C, and blow argon into the mixed solution for 30 minutes under an argon atmosphere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com