Rare earth composite fluorescent material taking carbonate as matrix and preparation method thereof

A fluorescent material and rare earth composite technology, applied in the field of fluorescent materials, can solve the problems of difficult recovery of rare earth complexes, poor light and thermal stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

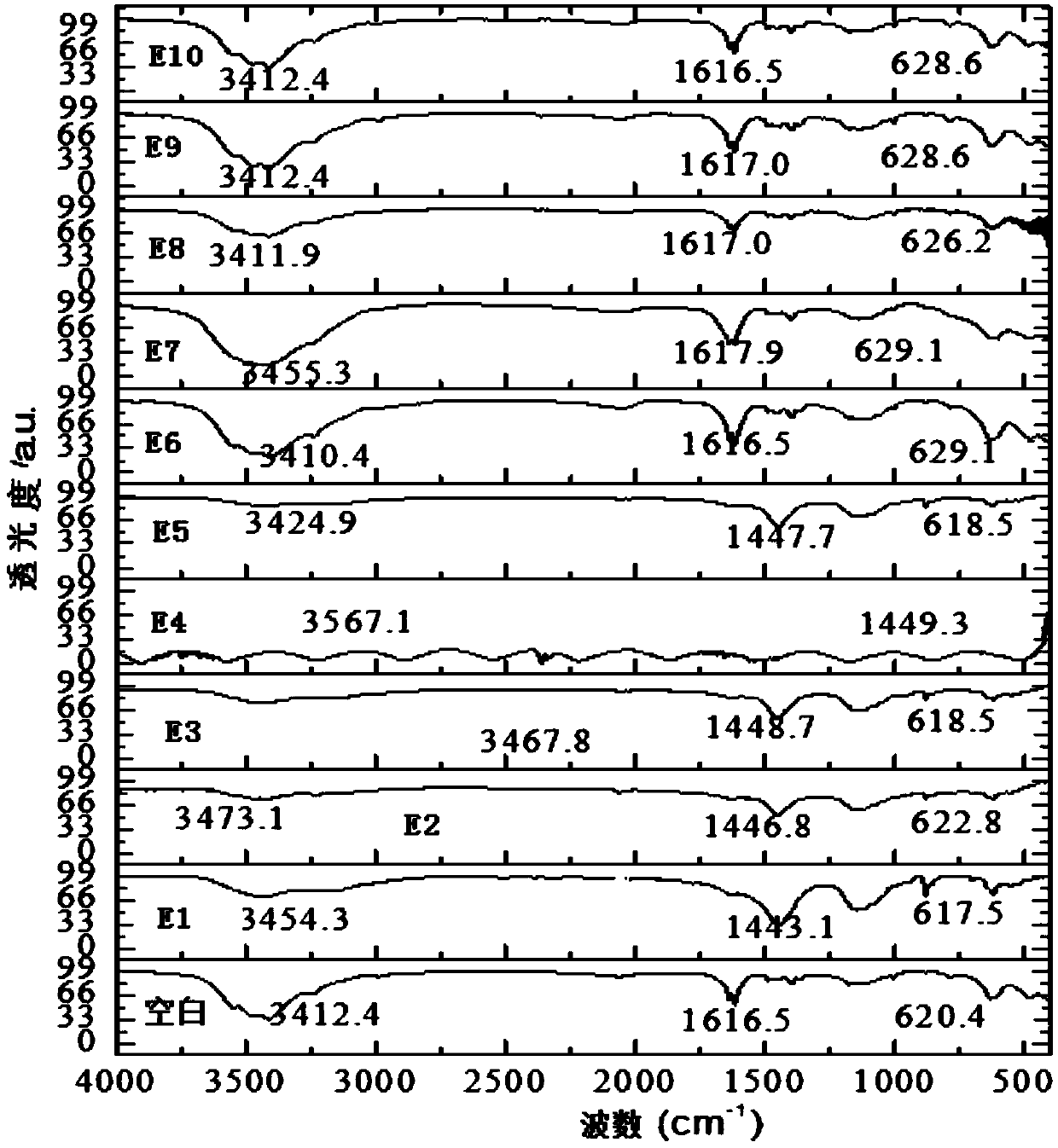

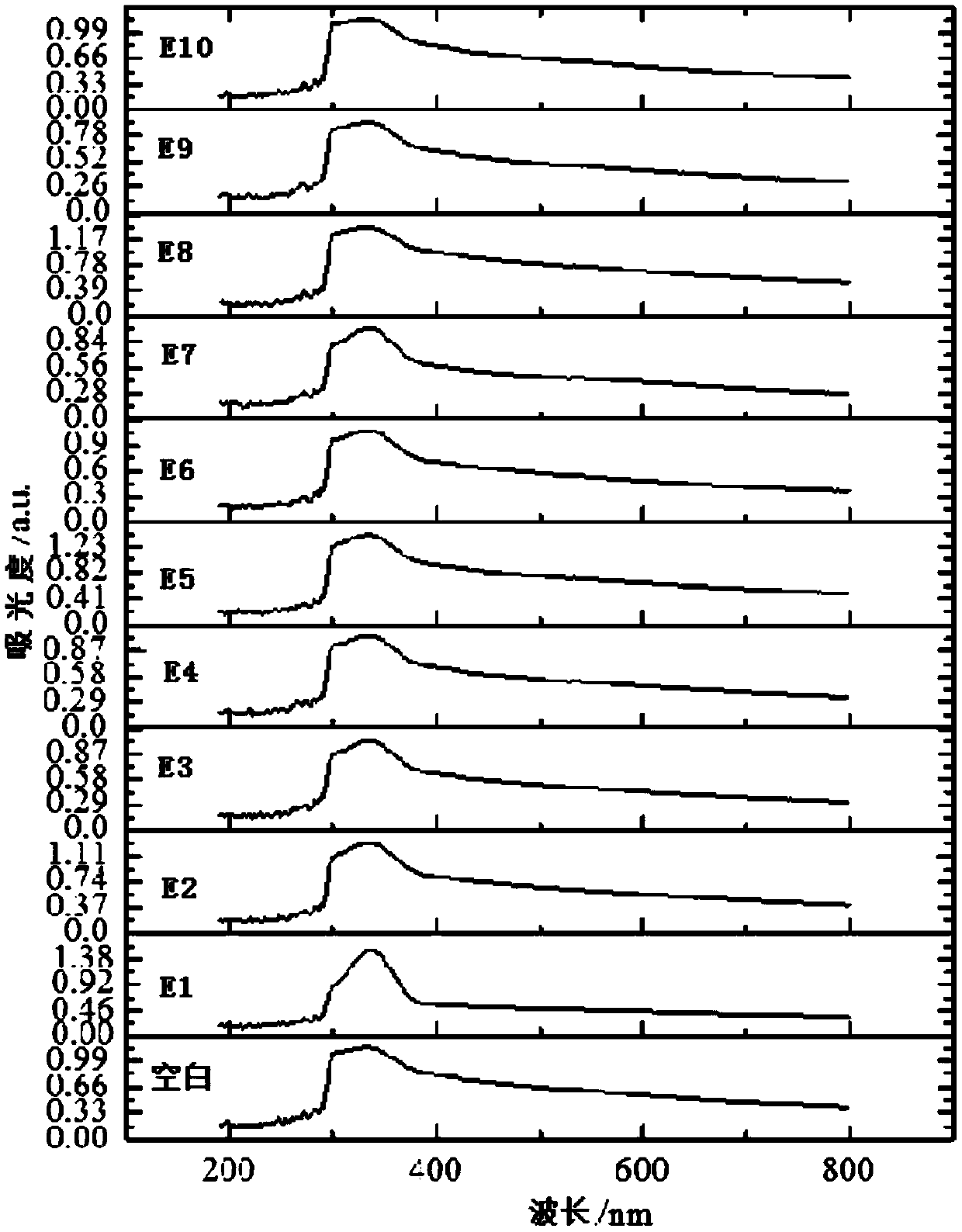

Method used

Image

Examples

preparation example Construction

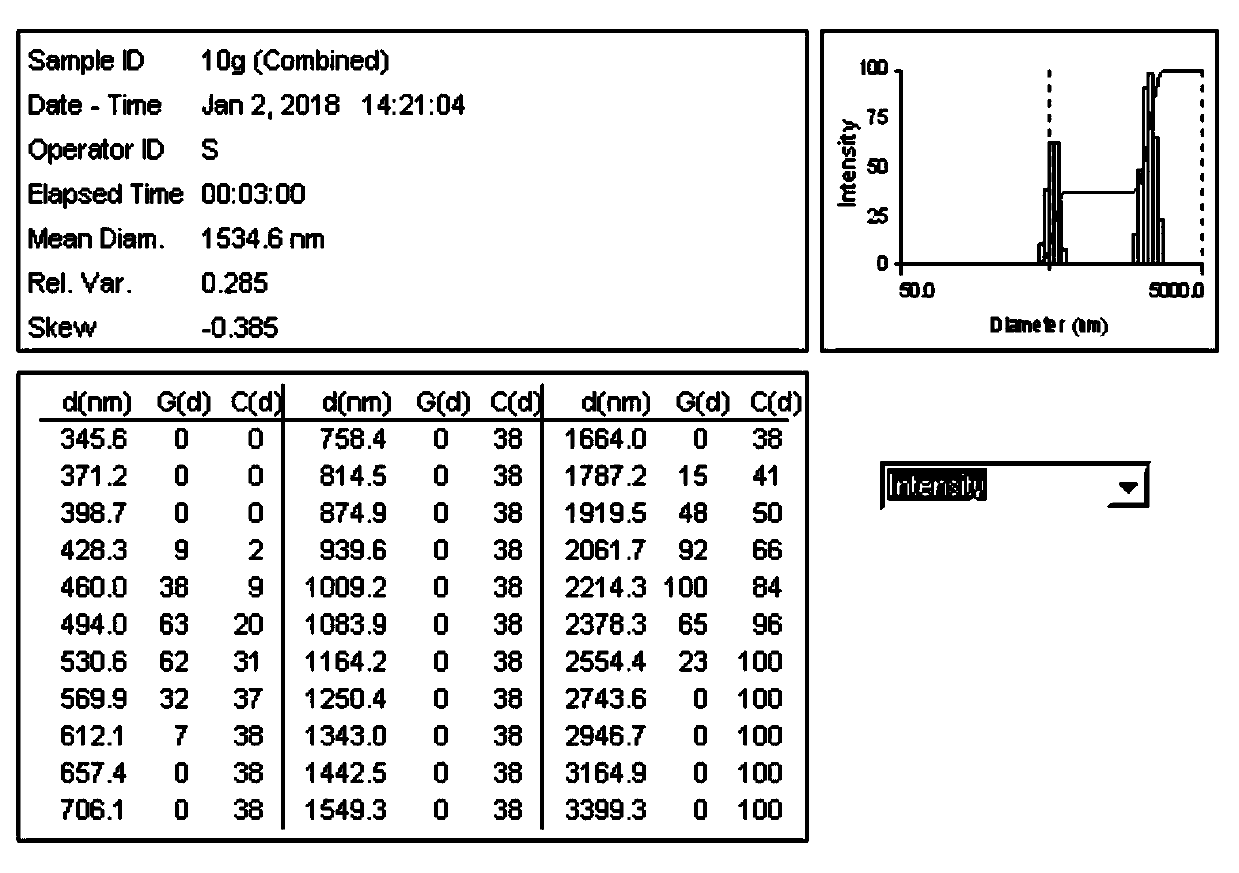

[0094] (1) The preparation method of the composite fluorescent material is simple and easy;

[0095] (2) The composite fluorescent material has high fluorescence excitation intensity, high fluorescence emission intensity, high quantum yield, and long fluorescence lifetime;

[0096] (3) The particle size of the composite fluorescent material prepared by the method of the present invention is uniform and can be controlled within an appropriate particle size range;

[0097] (4) The cost of the composite fluorescent material of the present invention is low, and it is expected to expand the application range of rare earth luminescent materials.

Embodiment 1

[0100] Weigh 1.0000g of dried sodium carbonate into a 50ml beaker, add 10ml of absolute ethanol, put it into an ultrasonic cleaner, seal the mouth of the beaker with plastic wrap, and perform ultrasonic vibration for 30min;

[0101] Weigh 0.2780g of TPPO (1mmol), 0.3339g of TTA (1.5mmol) and 0.1294g of europium chloride hexahydrate respectively into the reaction flask, then add 20mL of absolute ethanol, stir, and ultrasonically vibrate for 30min to obtain a solution ;

[0102] Place the above-mentioned reaction bottle in the heating mantle, turn on the stirring, and connect the reflux device, then drop the pretreated sodium carbonate solution into the reaction bottle, after 10 minutes, the dropwise addition is completed, heat to reflux reaction, and react for 2 hours;

[0103] After completion of the reaction, cool down to room temperature, filter, and put the obtained filter cake into an oven for drying at a temperature of 100°C for 3 hours to obtain the product; denoted as E...

Embodiment 2

[0105] Present embodiment is identical with the method used in embodiment 1, and difference only is that the consumption of sodium carbonate is different, and the consumption of present embodiment sodium carbonate is 2g; The product obtained is denoted as E2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com