Method for preparing fresh rice wine by utilizing ultrahigh-pressure sterilization

A technology for ultra-high pressure sterilization and fresh rice wine, applied in the field of wine preparation, can solve the problems of short storage time of rice wine, low yield of fermented wine, incapability of commercial production, etc. The effect of saccharification fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

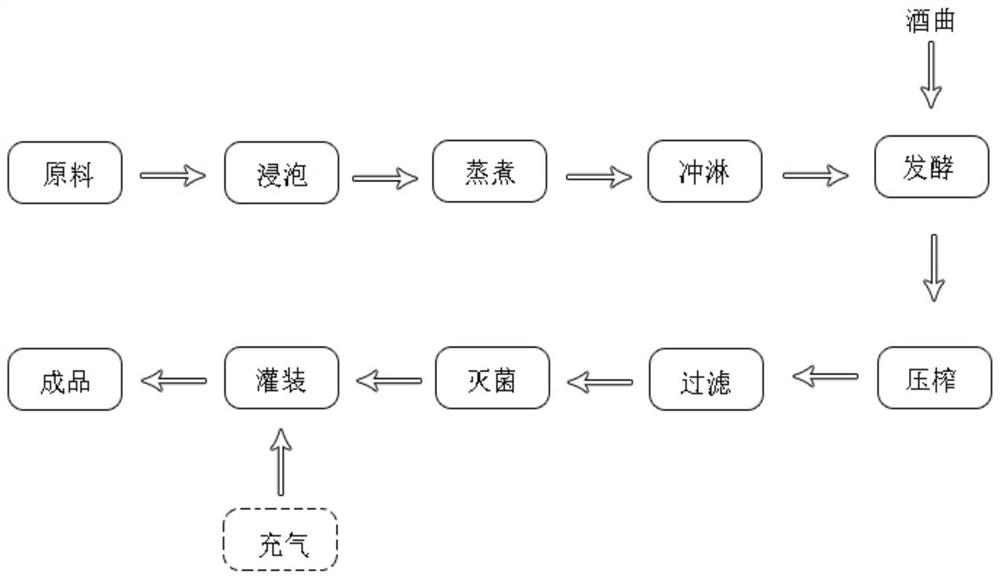

Method used

Image

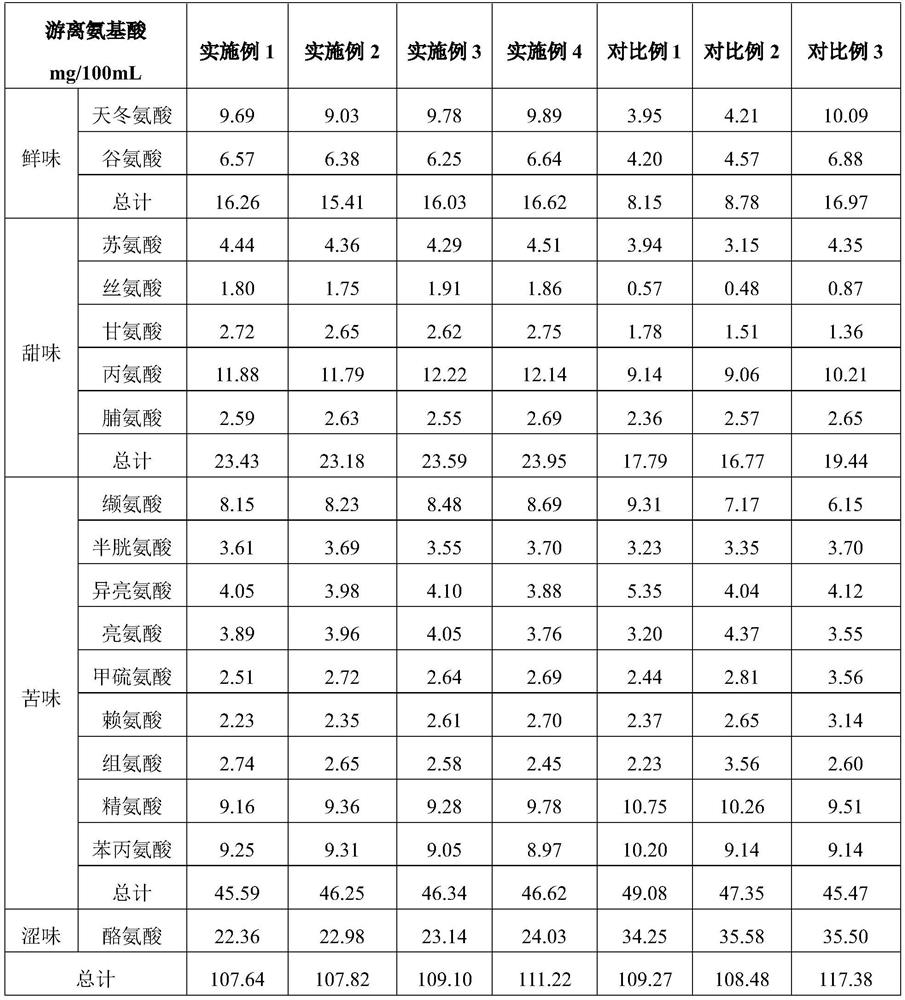

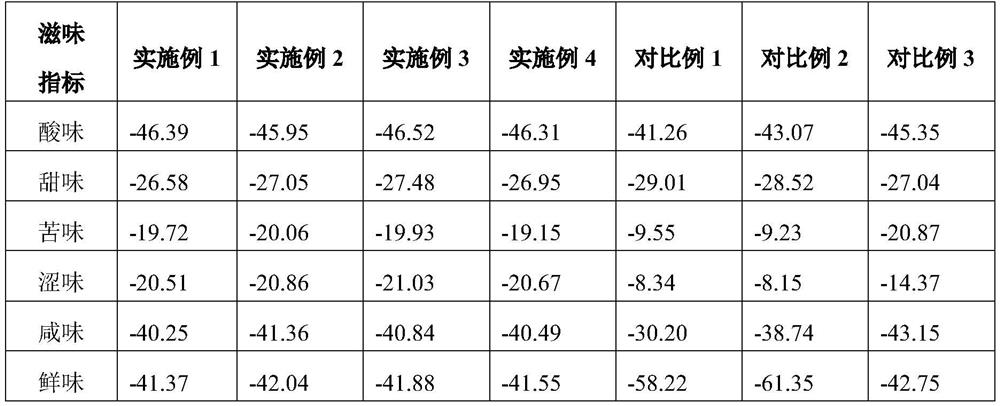

Examples

Embodiment 1

[0090] A preparation method of fresh rice wine mainly comprises the following steps:

[0091] (1) Rice soaking: choose fresh, non-mouldy glutinous rice, remove the dust, chaff and sundries attached to the surface of the rice grains, add water to the glutinous rice so that the mass ratio of glutinous rice to water is 1:2, at room temperature Soak for 10 hours;

[0092] (2) Cooking: steaming the soaked glutinous rice for 20 minutes;

[0093] (3) Rinse: rinse the steamed glutinous rice with tap water to separate and cool the rice grains so that the temperature of the glutinous rice is maintained at 30°C;

[0094] (4) Fermentation: Put glutinous rice and distiller's yeast into the fermenter in turn and stir evenly, wherein the amount of distiller's yeast added is 0.1% of the weight of glutinous rice. After stacking and fermenting at 28°C for 2 days, add water that is 1 times the weight of glutinous rice as the raw material, and stir evenly , continue the incubation and fermentat...

Embodiment 2

[0099] A preparation method of fresh rice wine mainly comprises the following steps:

[0100] (1) Rice soaking: select fresh, non-mouldy glutinous rice, remove the dust, chaff and sundries attached to the surface of the rice grains, add water to the glutinous rice so that the mass ratio of glutinous rice to water is 1:3, and soak at room temperature 15h;

[0101] (2) Cooking: steaming the soaked glutinous rice for 25 minutes;

[0102] (3) Showering: Showering the steamed glutinous rice with tap water to separate and cool the rice grains so that the temperature of the glutinous rice after soaking is kept at 32°C;

[0103] (4) Fermentation: Put glutinous rice and distiller's yeast into the fermenter successively and stir evenly, wherein, the addition amount of distiller's yeast is 0.2% of the weight of glutinous rice, after stacking and fermenting at 30°C for 3 days, add water twice the weight of raw glutinous rice, and stir evenly , continue the incubation and fermentation at...

Embodiment 3

[0108] A preparation method of aerated fresh rice wine mainly comprises the following steps:

[0109] (1) Rice soaking: choose fresh, non-mouldy glutinous rice, remove the dust, chaff and sundries attached to the surface of the rice grains, add water to the glutinous rice so that the mass ratio of glutinous rice to water is 1:2, at room temperature Soak for 12 hours;

[0110] (2) Cooking: steaming the soaked glutinous rice for 20 minutes;

[0111] (3) Rinse: rinse the steamed glutinous rice with tap water to separate and cool the rice grains so that the temperature of the glutinous rice is maintained at 30°C;

[0112] (4) Fermentation: Put glutinous rice and distiller's yeast into the fermenter successively and stir evenly, wherein, the addition amount of distiller's yeast is 0.1% of the weight of glutinous rice, after stacking and fermenting at 28°C for 2 days, add water 4 times the weight of raw glutinous rice, and stir evenly , continue the incubation and fermentation at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com