Production process and production equipment of breathable antiskid cool jacquard shell fabric

A production process and jacquard surface technology, applied in the field of prevention and treatment, can solve the problems of poor air permeability and wear resistance, defective finished patterns, easy sliding of fabrics, etc., and achieve the effect of increasing the anti-skid type, increasing the dyeing speed, and improving the flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A production process of air-permeable and non-slip cool jacquard face cloth is specifically carried out according to the following steps:

[0031] S1: Prepare raw materials

[0032] Prepare cotton, hemp, silk wool, lyocell fiber, PLA fiber, tencel and cupro fiber yarn, twist the tencel and cupro fiber yarn into double-ply warp yarn, and twist the cotton-linen silk wool and lyocell fiber into double-ply weft yarn , Twist the PLA fibers into one strand individually;

[0033] S2: raw material dyeing

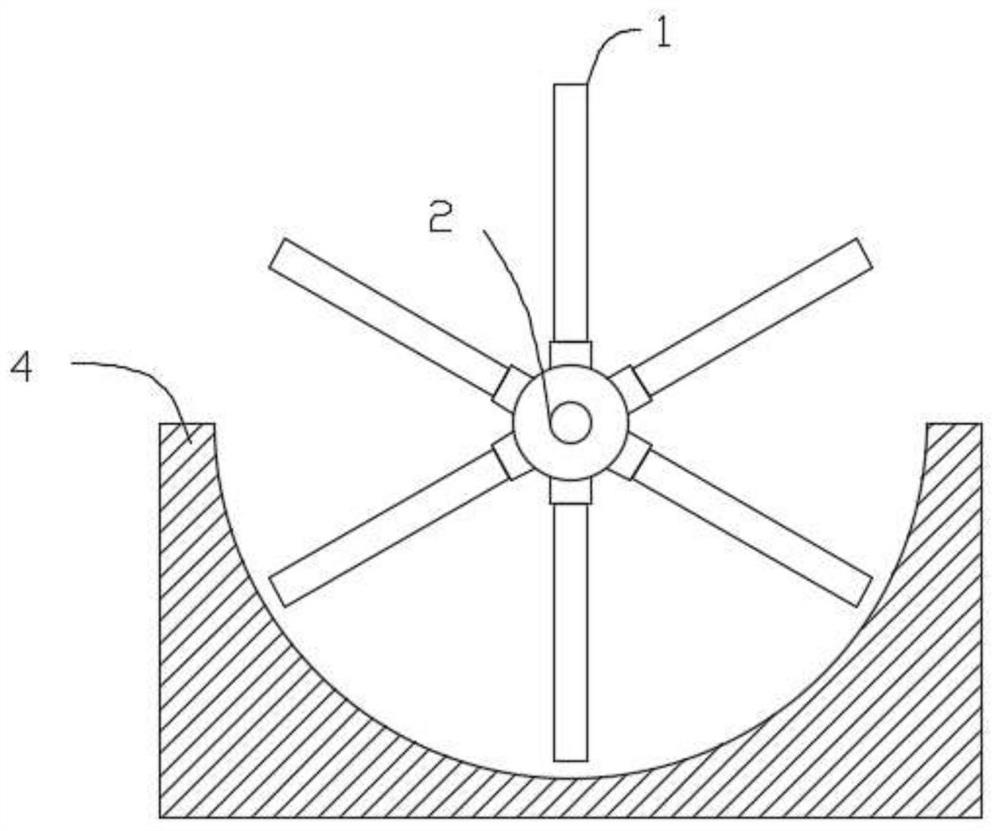

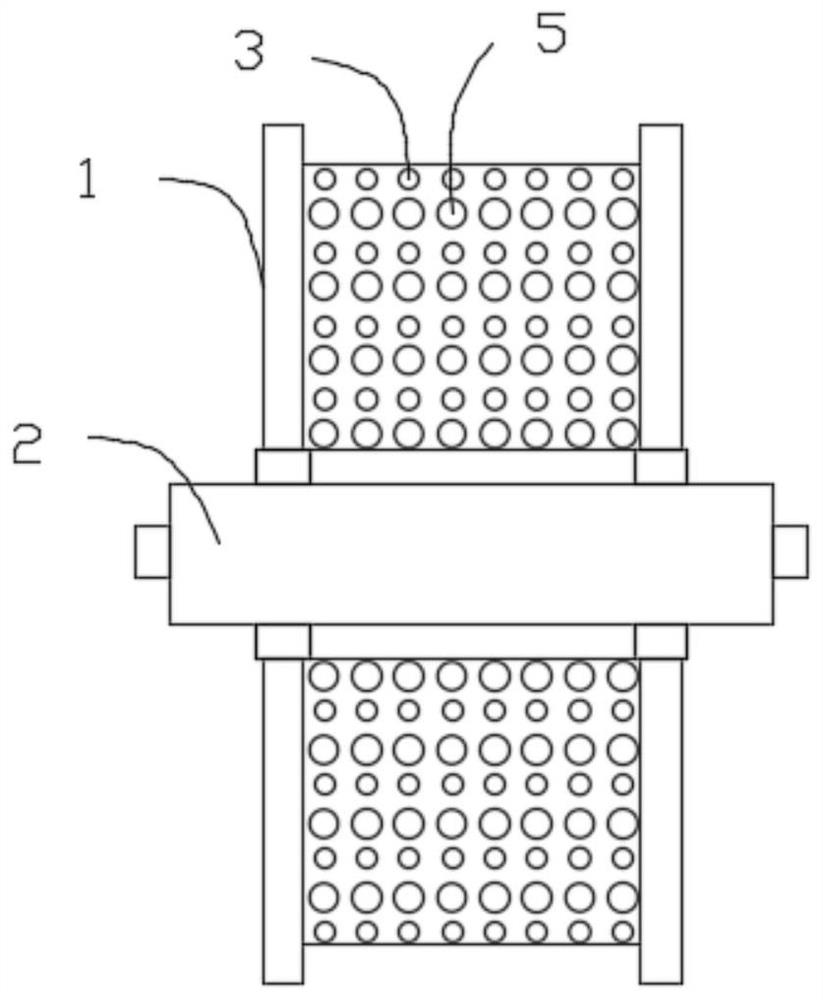

[0034] Pass the woven thread selected in S1 through a metal cylinder with a surface temperature of 220°C, set the rotating speed of the cylinder to 60rmin, remove the fluff on the surface of the woven thread, and support the woven thread from which the fluff has been removed by multiple support rollers 1, and pass through The driving roller 2 in the middle is driven for dyeing, the rotating speed of the driving roller 2 is set to be 2r / h, and the rotation angle is 180°. The...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is:

[0048] A production process of air-permeable and non-slip cool jacquard face cloth is specifically carried out according to the following steps:

[0049] S1: Prepare raw materials

[0050] Prepare cotton, hemp, silk wool, lyocell fiber, PLA fiber, tencel and cupro fiber yarn, twist the tencel and cupro fiber yarn into double-ply warp yarn, and twist the cotton-linen silk wool and lyocell fiber into double-ply weft yarn , Twist the PLA fibers into one strand individually;

[0051] S2: raw material dyeing

[0052] Pass the woven thread selected in S1 through a metal cylinder with a surface temperature of 280°C, set the rotating speed of the cylinder to 70r / min, remove the fluff on the surface of the woven thread, and support the woven thread from which the fluff has been removed by multiple support rollers 1 , dyeing is driven by the driving roller 2 in the middle, the rotating speed of the driving roller 2 is ...

Embodiment 3

[0061] The difference between embodiment 3 and embodiment 2 is:

[0062] A production process of air-permeable and non-slip cool jacquard face cloth is specifically carried out according to the following steps:

[0063] S1: Prepare raw materials

[0064] Prepare cotton, hemp, silk wool, lyocell fiber, PLA fiber, tencel and cupro fiber yarn, twist the tencel and cupro fiber yarn into double-ply warp yarn, and twist the cotton-linen silk wool and lyocell fiber into double-ply weft yarn , Twist the PLA fibers into one strand individually;

[0065] S2: raw material dyeing

[0066] Pass the woven thread selected in S1 through a metal cylinder with a surface temperature of 380°C, set the rotating speed of the cylinder to 80r / min, remove the fluff on the surface of the woven thread, and support the woven thread from which the fluff has been removed by multiple support rollers 1 , dyeing is driven by the drive roller 2 in the middle, the rotating speed of the drive roller 2 is set ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com