Paper protection method for improving surface hydrophobicity

A hydrophobic, paper-like technology, used in papermaking, paper coating, physical treatment of paper, etc., can solve the problems of ink marks, dyes, information damage on paper surface, complicated processing technology, etc., and achieve stable hydrophobicity and easy operation. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The filter paper to be treated (double circled filter paper, Waterman Company) was activated with cold plasma, which was generated by air dielectric barrier discharge, with a power supply voltage of 80V and a current of 0.25A. Then soak the filter paper in 0.5 mol / L sodium hydroxide solution to provide an alkaline environment on the surface of the paper, then apply 0.2 mol / L zinc acetate dihydrate solution to the paper, and react for 15 minutes to generate zinc oxide Precursor, and finally put the treated paper into an oven at 80°C for dehydration reaction for 12 hours, so that the zinc oxide precursor on the surface of the paper is dehydrated to form zinc oxide crystals.

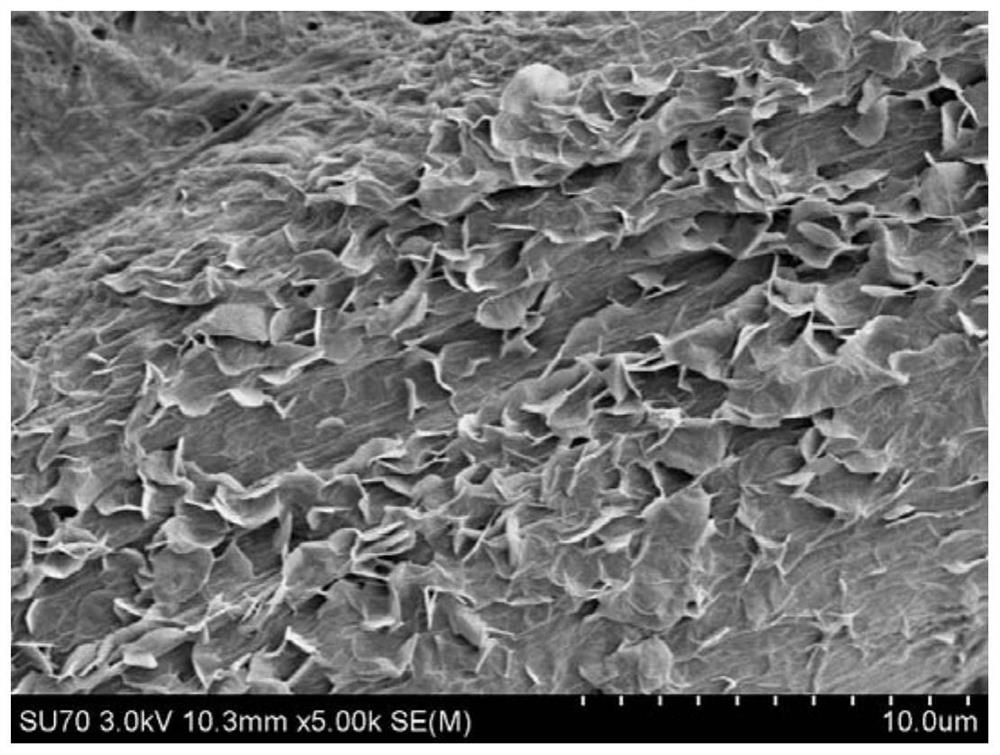

[0041] The SEM picture of the filter paper / zinc oxide composite material prepared in this embodiment is as follows figure 1 As shown, it can be seen that the flaky zinc oxide is uniformly distributed on the paper fiber surface, this is because after the paper is pretreated by plasma activation, the s...

Embodiment 2

[0048] The filter paper to be treated (double delimitation filter paper, Waterman company) is soaked in the sodium hydroxide solution of 0.5mol / L, provides an alkaline environment on the paper surface, and then the dihydrate zinc acetate of 0.2mol / L The solution was applied to the paper and reacted for 15 minutes to form a zinc oxide precursor. Finally, the treated paper was placed in an oven at 80°C for 12 hours for dehydration to dehydrate the zinc oxide precursor on the surface of the paper to form zinc oxide crystals.

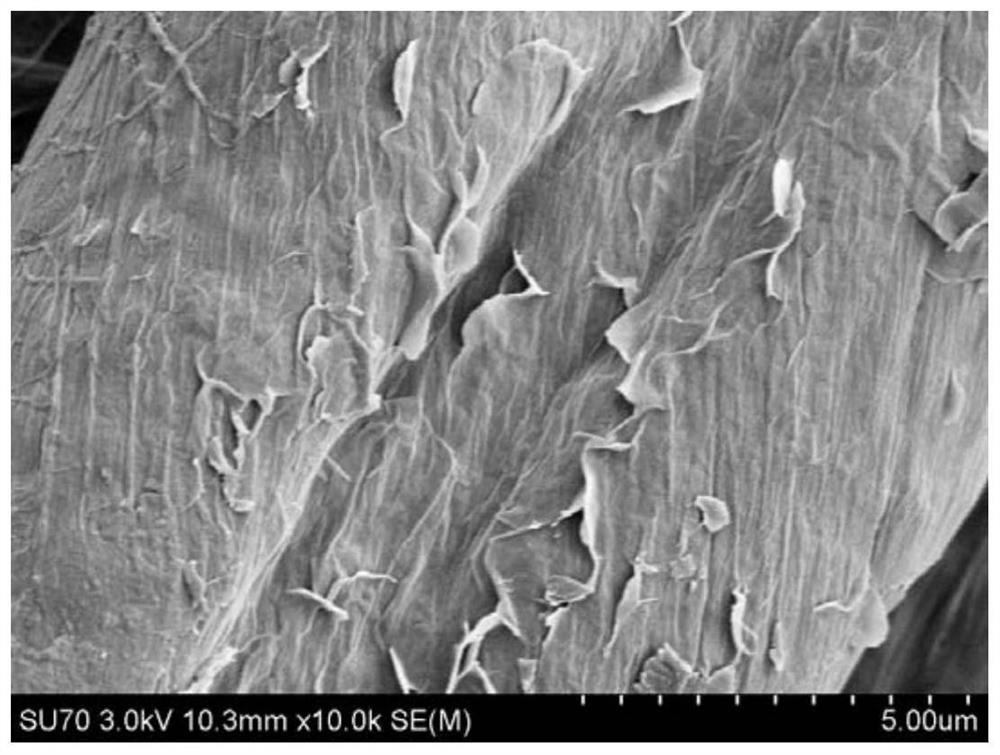

[0049] The SEM picture of the filter paper / zinc oxide composite material prepared in this embodiment is as follows figure 2 As shown, since the paper has not been pretreated by plasma activation, it can be seen that the distribution of zinc oxide on the paper fibers is not uniform, and the loading amount of zinc oxide is not much compared to that of Example 1.

[0050] Performance Testing:

[0051] Get the untreated filter paper of the same type as in Exa...

Embodiment 3

[0056] The concentration of the zinc acetate dihydrate solution in Example 1 was adjusted to 0.1 mol / L, and the rest of the steps were the same as in Example 1.

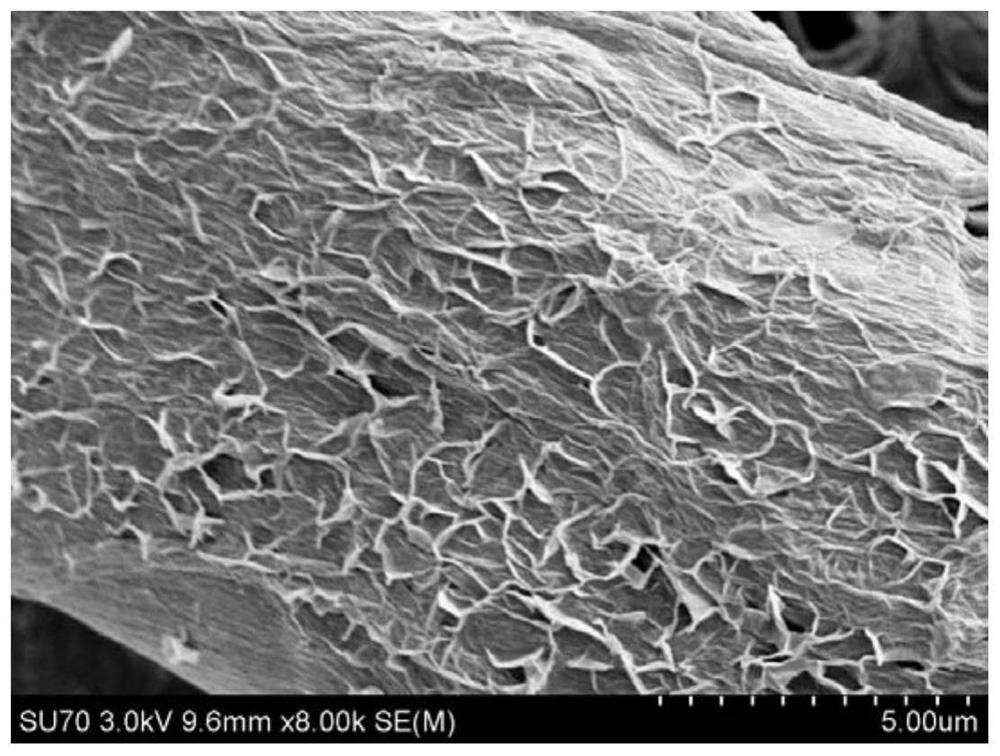

[0057] The SEM of the filter paper / zinc oxide composite material finally prepared after the treatment of embodiment 3 is as follows: image 3 As shown, it can be seen that the morphology of the final loaded zinc oxide is similar to that of Example 1, but due to the low concentration of the zinc source solution, zinc oxide lacks power in the process of nucleation and growth, and most of the loaded zinc oxide does not completely form a sheet shape, eventually leading to a decrease in the contact angle of the filter paper with the aqueous solution after loading zinc oxide compared with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com