Flat plate type laser and method for improving optical power density

A laser, flat-panel technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve problems such as the decrease of optical power density, and achieve the effect of reducing the volume, reducing the volume per unit power, and improving the optical power density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

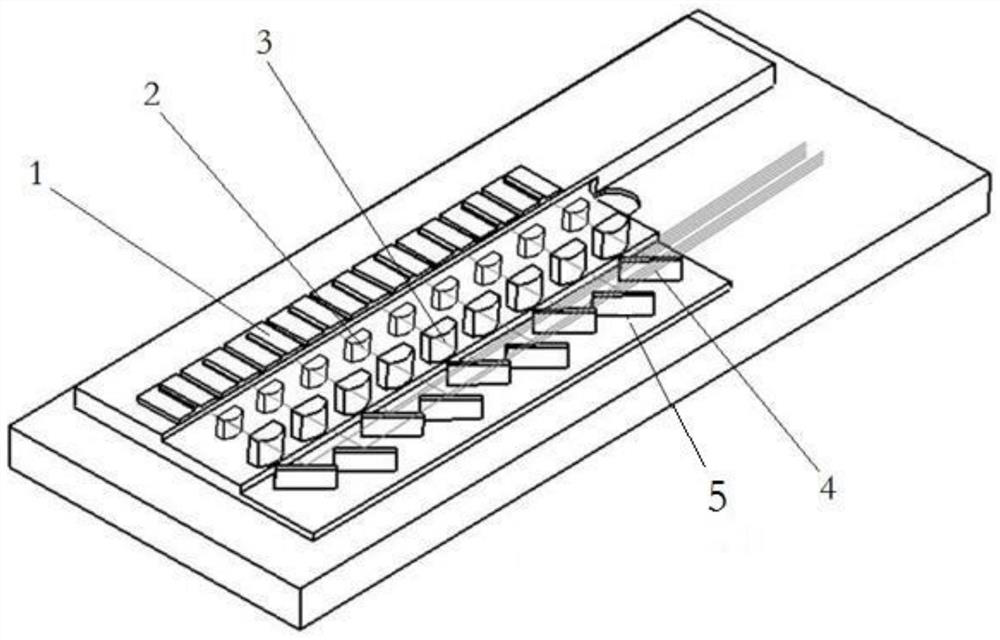

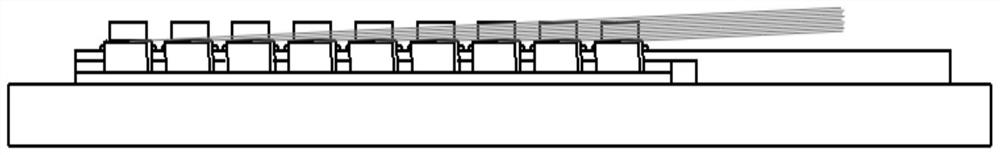

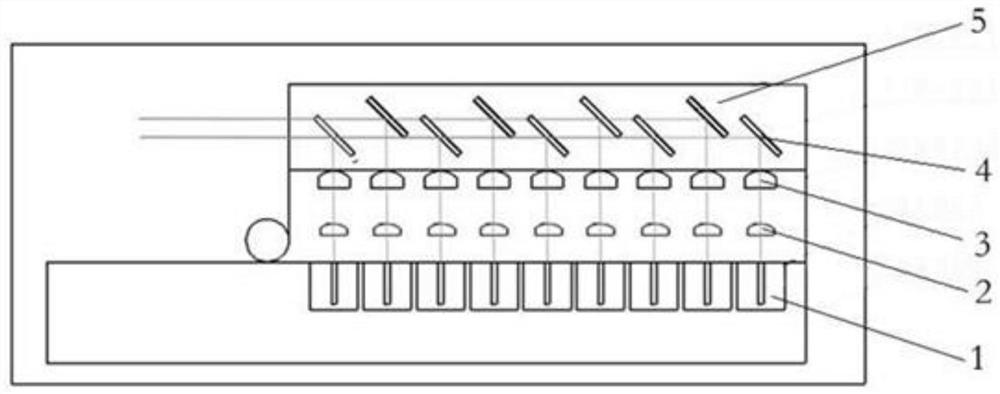

Embodiment 1

[0032] The reflectors include a first row of reflectors and a second row of reflectors, the first row of reflectors and the second row of reflectors are arranged alternately, the central axes of the first row of reflectors and the second row of reflectors do not coincide, and this In the scheme, the far-field spot of the laser beam is hit at one point, and the near-field spot is divided into two rows. There are two types of mirror adjustments. One is the outermost mirror, called the second row of mirrors. After adjustment, adjust the inner mirror, that is, the first row of mirrors 4. A first row of reflectors and a second row of reflectors are arranged alternately. Because the two types of reflectors have two rows of near-field spots, the actual arrangement of the reflectors is also divided into two rows. The laser reflectors with near-field spots in the same row are in the same row. The beam passes through the two rows of mirrors without blocking each other, so the equivalen...

Embodiment 2

[0034] When the number of chips in the laser is large, when the two rows of light spots cannot balance the light spots in the direction of the fast and slow axes, there may be N=3. At this time, three rows of mirrors are arranged alternately. After the laser beam passes through the focusing lens, three rows of light spots are formed in the near field. When the light spot is arranged, the elevation angle of the reflector is further reduced, and the beam density is further increased.

Embodiment 3

[0036] According to a flat-panel laser, a flat-panel laser and a method for increasing optical power density are also provided:

[0037] (1) The laser diodes are arranged in a single row on the bottom plate;

[0038] (2) The light beam emitted by each laser diode is first collimated by the fast-axis collimating lens, and the light beam becomes parallel light in the fast-axis direction, that is, the direction perpendicular to the laser chip;

[0039] (3) The light beam passes through the fast axis collimating lens and then passes through the slow axis collimating lens, and the light beam becomes parallel light in the direction of the slow axis, that is, along the direction of the chip;

[0040] (4) After the fast and slow axes are collimated, the beam is deflected by 90 degrees through the mirror;

[0041] (5) The elevation angle of the first row of reflectors is the same as that of the second row of reflectors, and they are arranged on the base plate at different optical dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com