Stainless steel cladding steel plate and manufacturing method thereof

A technology of stainless steel layer and manufacturing method, which is applied in the manufacture of stainless steel clad steel plates and the field of stainless steel clad steel plates, can solve the problems affecting the safety of buildings, the decrease of toughness indicators such as elongation, and low yield strength, so as to improve the corrosion resistance Performance, improved integrity and consistency, improved security effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

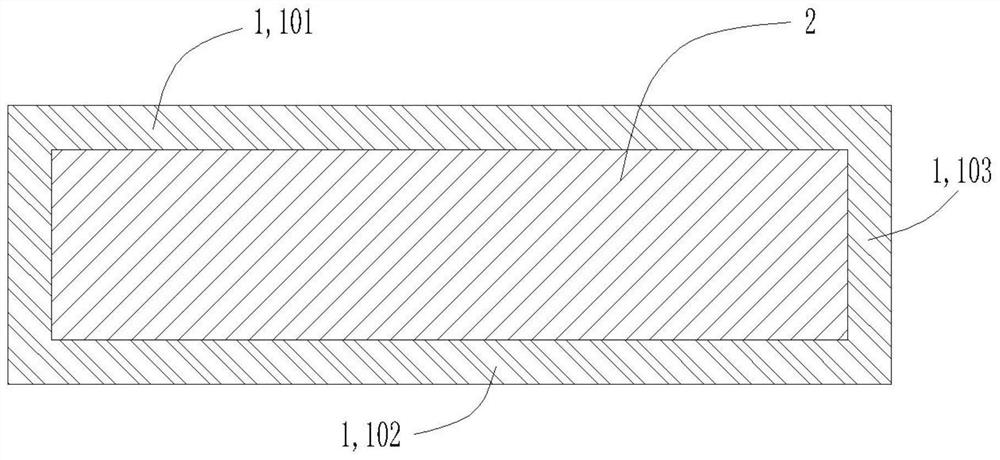

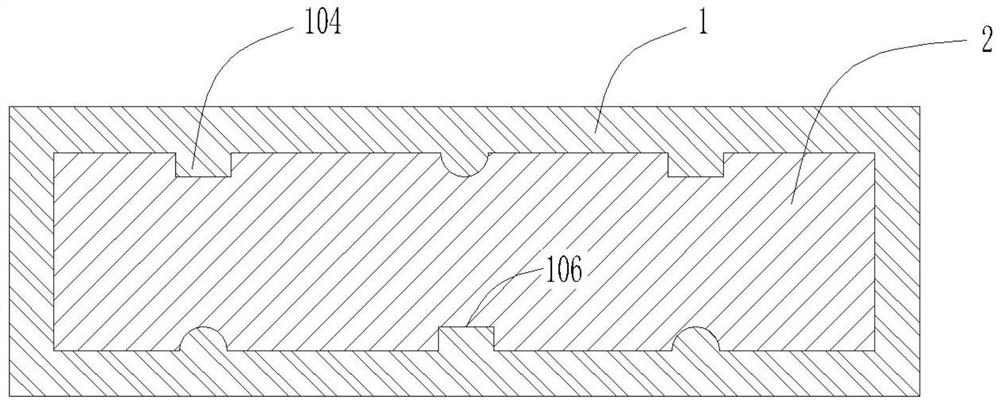

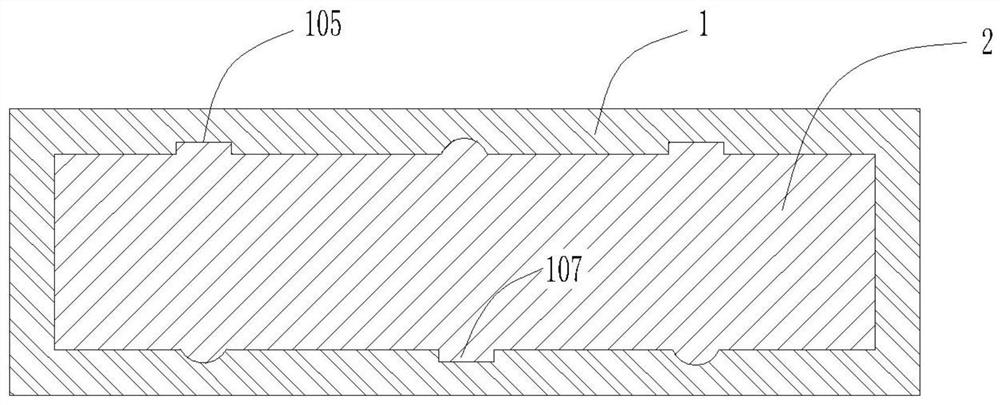

[0041] Please refer to Figure 1 to Figure 5 , a stainless steel clad steel plate in this embodiment, the clad steel plate includes: an outer stainless steel layer 1 and an inner steel core layer 2, the outer stainless steel layer 1 is wrapped around the outer circumference of the inner steel core layer 2, and the outer stainless steel layer The layer 1 and the inner steel core layer 2 are formed by hot rolling, the outer stainless steel layer 1 is formed by hot rolling of stainless steel pipe, and the inner steel core layer 2 is a steel mandrel that is compatible with the outer stainless steel layer 1. Hot-rolled forming, the outer stainless steel layer 1 and the inner steel core layer 2 are metallurgically bonded.

[0042] The outer stainless steel layer 1 includes a stainless steel upper layer 101, a stainless steel lower layer 102 and a stainless steel side wall layer 103. The thickness of the stainless steel upper layer 101, the stainless steel lower layer 102 and the sta...

Embodiment 2

[0048] Please refer to Figure 1 to Figure 7 , the manufacturing method of a kind of stainless steel cladding steel plate of this embodiment, this manufacturing method comprises the following steps:

[0049] In step 1, the stainless steel pipe for making the outer stainless steel layer 1 and the steel mandrel for making the inner steel core layer 2 are respectively cleaned and impurity-removed, and the inner and outer parts of the stainless steel pipe are cleaned by shot blasting, pickling or machining. The oxide scale on the surface is removed, and the oxide scale on the outer surface of the steel mandrel is removed by shot peening or pickling or machining; There is a surface contact fit or a gap fit;

[0050] Put the clad steel sheet blank into the vacuum chamber and then pump it into a vacuum, and seal both ends of the clad steel sheet blank by welding in a vacuum environment, so that a closed vacuum environment is formed between the stainless steel pipe and the steel mand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com