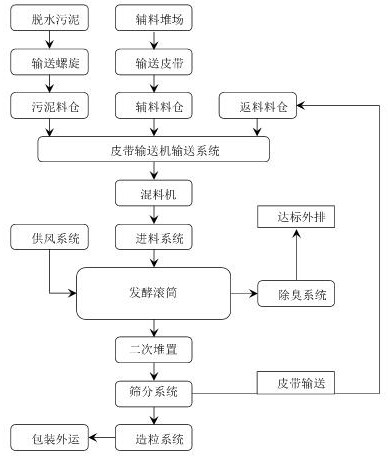

Method for producing organic fertilizer through dynamic fermentation of sludge

A dynamic fermentation and organic fertilizer technology, which is applied in the preparation of organic fertilizers, organic fertilizers, organic fertilizer equipment, etc., can solve the problems of low efficiency and poor fermentation effect, and achieve improved soil environment, enhanced abundance, and good fermentation effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a method for producing organic fertilizer by dynamic fermentation of sludge, said method comprising the steps of:

[0037] Dewater the sludge to a water content of 60%, a pH of 8, and organic matter > 30%.

[0038] Mix 1 part of rice husk, 1 part of corn, 2 parts of mushroom residue, 1 part of peanut shell powder, 1 part of furfural residue, 5 parts of Jerusalem artichoke straw, 1 part of Jerusalem artichoke flower powder, and 0.5 part of grape seed powder. <10%, particle size between 5mm-20mm.

[0039] Mix the dehydrated sludge and auxiliary materials evenly to obtain a mixture. The moisture content of the mixture is 55%, the C / N ratio is 20:1, and the amount of auxiliary materials added is 15% of the weight of the dehydrated sludge.

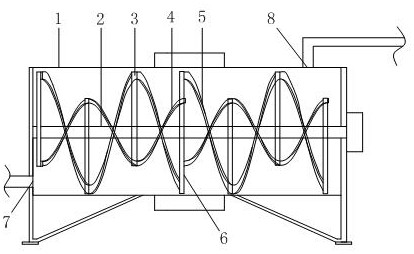

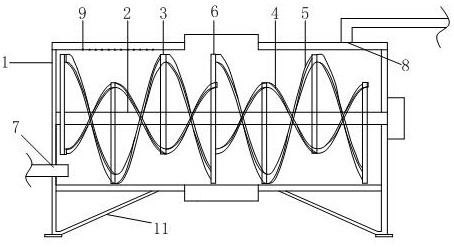

[0040] The mixture and the air are sent into the fermentation drum 1 at the same time, and the fermentation drum 1 is a cylindrical structure placed horizontally, and the internal spiral stirring blade 4 ...

Embodiment 2

[0048] The present embodiment provides a method for producing organic fertilizer by dynamic fermentation of sludge, said method comprising the steps of:

[0049] Dewater the sludge to a water content of 85%, a pH of 6, and organic matter > 30%.

[0050] Mix 3 parts of rice husk, 2 parts of corn, 4 parts of mushroom residue, 3 parts of peanut shell powder, 3 parts of furfural residue, 8 parts of Jerusalem artichoke straw, 2 parts of Jerusalem artichoke flower powder, and 1.5 parts of grape seed powder. <10%, the particle size of the mixture is between 5mm-20mm.

[0051] Mix the dehydrated sludge and auxiliary materials evenly to obtain a mixture. The water content of the mixture is 60%, the C / N ratio is 30:1, and the amount of auxiliary materials added is 15% of the weight of the dehydrated sludge.

[0052] The mixture and the air are sent into the fermentation drum 1 at the same time, and the fermentation drum 1 is a cylindrical structure placed horizontally, and the internal...

Embodiment 3

[0059] The present embodiment provides a method for producing organic fertilizer by dynamic fermentation of sludge, said method comprising the steps of:

[0060] Dewater the sludge to a water content of 80%, a pH of 7, and organic matter > 30%.

[0061] Mix 2 parts of rice husk, 3 parts of wheat straw, 3 parts of mushroom residue, 2 parts of peanut shell powder, 2 parts of furfural residue, 6 parts of Jerusalem artichoke straw, 1 part of Jerusalem artichoke flower powder, and 1 part of grape seed powder to obtain auxiliary materials. Rate <10%, particle size between 5mm-20mm.

[0062] Mix the dehydrated sludge and auxiliary materials evenly to obtain a mixture. The water content of the mixture is 60%, the C / N ratio is 25:1, and the amount of auxiliary materials added is 15% of the weight of the dehydrated sludge.

[0063] The mixture and the air are sent into the fermentation drum 1 at the same time, and the fermentation drum 1 is a cylindrical structure placed horizontally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com