Preparation method of high-efficiency low-cost acidic color fixing agent

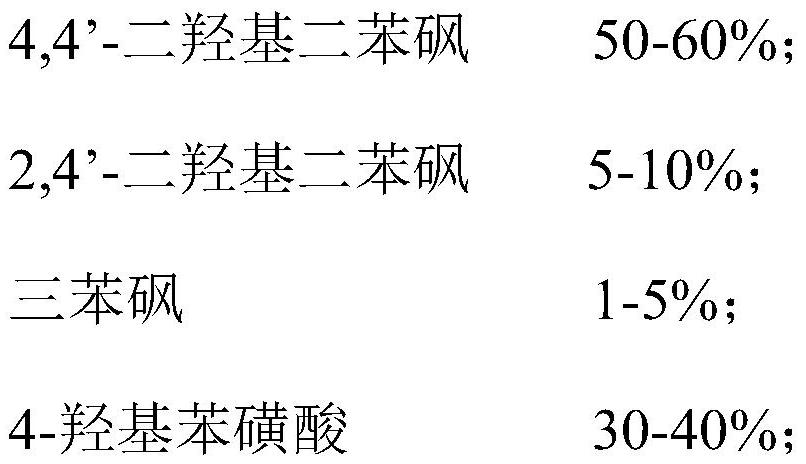

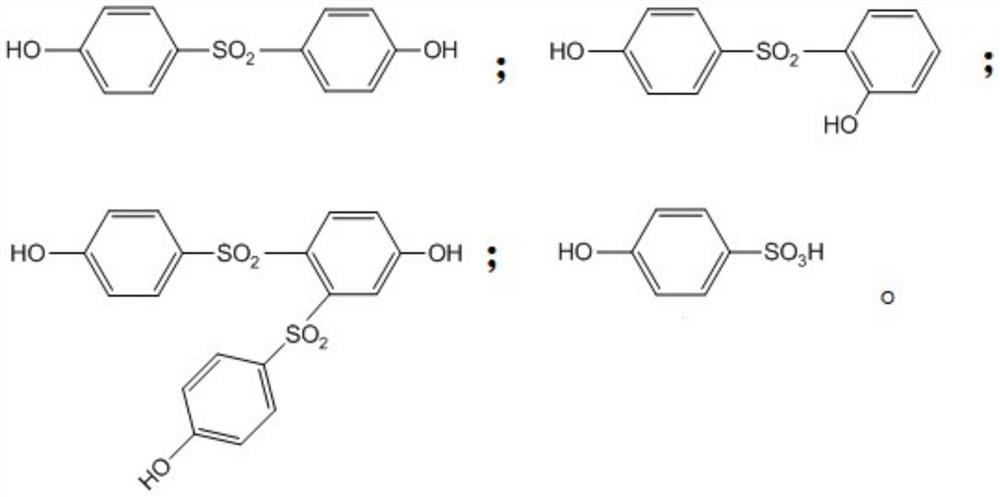

An acid color fixing agent, low-cost technology, applied in the preparation of sulfonic acid, preparation of organic compounds, dyeing method, etc., can solve the problems of poor water fastness, high production cost of raw materials, high processing cost, etc., to achieve production cost reduction , Good color fixing effect and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

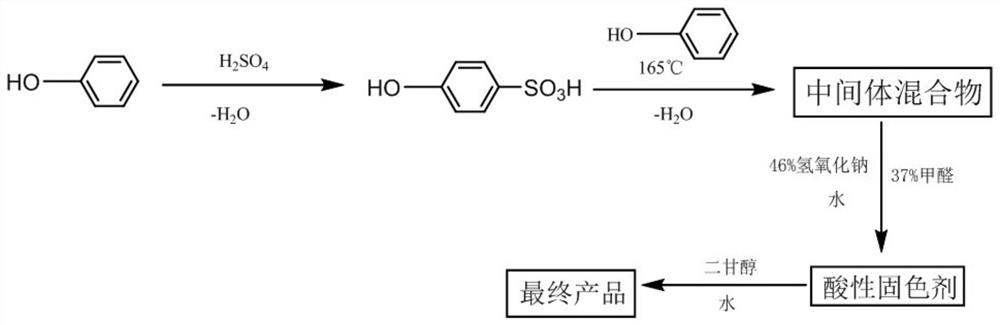

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing an acidic color fixing agent with high efficiency and low cost, comprising the following steps:

[0033] The first step intermediate synthesis:

[0034] Sulfonation reaction: phenol: 188g (2mol); concentrated H 2 SO 4 : 200g (2.04mol);

[0035] Sulfonation reaction: phenol: 178.6g (1.9mol);

[0036] Synthetic steps:

[0037] (1) Put 188g of phenol into a four-necked flask, heat up to 95°C, and slowly add 200g of concentrated H 2 SO 4 , control the dropping speed, so that the temperature is controlled at 95-100 °C, after the dropping is completed, start the heat preservation timer for 3 hours, record the temperature every 30 minutes, and observe the experimental phenomenon;

[0038] (2) The sulfonation is finished, and the acidity is measured, and the correct value is 27;

[0039] (3) Raise the temperature to 130°C, add 89.3g of phenol and continue to heat up to 165°C, start the heat preservation timer, start vacuumi...

Embodiment 2

[0047] This embodiment provides a method for preparing an acidic color fixing agent with high efficiency and low cost, comprising the following steps:

[0048] The first step intermediate synthesis:

[0049]Sulfonation reaction: phenol: 200g; concentrated H 2 SO 4 : 210g;

[0050] Sulfonation reaction: phenol: 188.6g;

[0051] Synthetic steps:

[0052] (1) Put 200g of phenol into a four-neck flask, heat up to 95°C, and slowly add 210g of concentrated H 2 SO 4 , control the dropping speed, so that the temperature is controlled at 95-100 °C, after the dropping is completed, start the heat preservation timer for 3 hours, record the temperature every 30 minutes, and observe the experimental phenomenon;

[0053] (2) The sulfonation is finished, and the acidity is measured, and the correct value is 27;

[0054] (3) Heat up to 130°C, add 94.3g of phenol and continue to heat up to 165°C, start the heat preservation timer, start vacuuming after 20 minutes, increase the vacuum de...

Embodiment 3

[0062] This embodiment provides a method for preparing an acidic color fixing agent with high efficiency and low cost, comprising the following steps:

[0063] The first step intermediate synthesis:

[0064] Sulfonation reaction: phenol: 180g; concentrated H 2 SO 4 : 195g;

[0065] Sulfonation reaction: phenol: 170g;

[0066] Synthetic steps:

[0067] (1) Put 180g of phenol into a four-necked flask, heat up to 95°C, and slowly add 195g of concentrated H 2 SO 4 , control the dropping speed, so that the temperature is controlled at 95-100 °C, after the dropping is completed, start the heat preservation timer for 3 hours, record the temperature every 30 minutes, and observe the experimental phenomenon;

[0068] (2) The sulfonation is finished, and the acidity is measured, and the correct value is 28;

[0069] (3) Raise the temperature to 130°C, add 85g of phenol and continue to heat up to 165°C, start the heat preservation timer, start vacuuming after 20 minutes, increase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com