PUR hot melt adhesive for composite board and preparation method of PUR hot melt adhesive

A technology of hot-melt adhesive and composite board, applied in the direction of adhesive, adhesive type, polyurea/polyurethane adhesive, etc., can solve the problems of high preparation cost, complicated preparation process, unfavorable industrialization development, etc., and achieve final adhesion High, excellent aging resistance, good tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

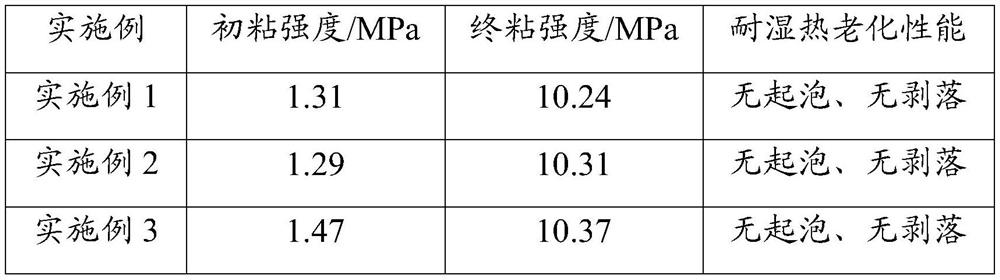

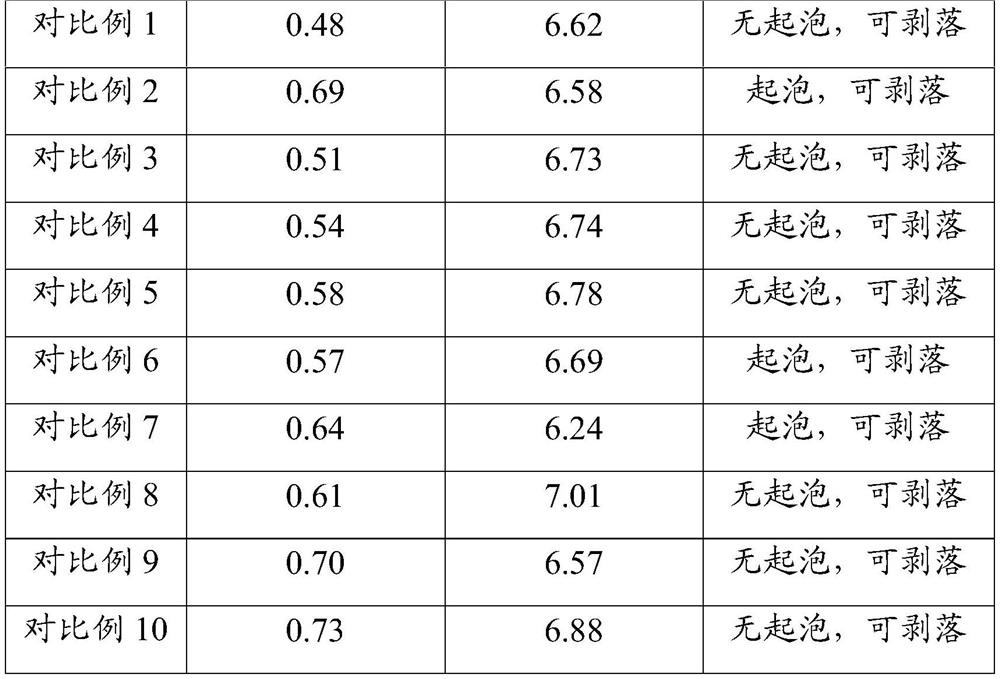

Examples

preparation example Construction

[0042] The second aspect of the present invention also provides a kind of preparation method of PUR hot-melt adhesive for composite board as described above, comprising the following steps:

[0043] S1, put the polyol polymer and thermoplastic resin into the reaction kettle, heat it to 110-120°C to melt it completely, vacuum dehydrate it under the condition of constant stirring until the water content is lower than 200ppm, then add polyisocyanate, under the protection of inert gas Next, stir and react for 2 to 3 hours, then add silane coupling agent and other additives, stir and react for 0.5 to 1 hour to obtain PUR hot melt adhesive.

[0044] The third aspect of the present invention provides an application of PUR hot melt adhesive for composite boards in the field of board composites.

Embodiment 1

[0048] Example 1 provides a PUR hot melt adhesive for composite boards, including 60 parts of polyol polymer, 25 parts of polyisocyanate, 20 parts of thermoplastic resin, 1 part of silane coupling agent, and 3 parts of other auxiliary agents in parts by weight. .

[0049] The polyol polymer includes 10% of crystalline polyester polyol, 45% of non-crystalline polyester polyol, 25% of polypropylene glycol and 20% of castor oil modified polyol by mass percentage.

[0050] The number-average molecular weight of the crystalline polyester polyol is 2000, and the hydroxyl value is 47-54 mgKOH / g (purchased from Kaiyin Chemical, brand: Evonik, model: Dynacoll 7362).

[0051] The number-average molecular weight of the non-crystalline polyester polyol is 2000, and the hydroxyl value is 50-60 mgKOH / g (purchased from Kaiyin Chemical, brand: Evonik, model: Dynacoll 7110).

[0052] The number average molecular weight of the polypropylene glycol is 900-1100, and the hydroxyl value is 102-125...

Embodiment 2

[0063] Embodiment 2 provides a PUR hot melt adhesive for composite boards, including 80 parts of polyol polymer, 35 parts of polyisocyanate, 30 parts of thermoplastic resin, 3 parts of silane coupling agent, and 7 parts of other auxiliary agents in parts by weight. .

[0064] The polyol polymer includes 15% of crystalline polyester polyol, 30% of non-crystalline polyester polyol, 25% of polypropylene glycol and 30% of castor oil modified polyol in terms of mass percentage.

[0065] The number-average molecular weight of the crystalline polyester polyol is 3500, and the hydroxyl value is 27-34 mgKOH / g (purchased from Kaiyin Chemical, brand: Evonik, model: Dynacoll 7360).

[0066] The number-average molecular weight of the non-crystalline polyester polyol is 3000, and the hydroxyl value is 31-39 mgKOH / g (purchased from Kaiyin Chemical, brand: Evonik, model: Dynacoll 7130).

[0067] The number average molecular weight of the polypropylene glycol is 1800-2200, and the hydroxyl va...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com